Updated December 26, 2024 Authors: Dr. Chris Cloney and Jon Barrett of Dust Safety Science

in a Food Processing Manufacturing Facility

Dust Explosion Risks in Wisconsin

Wisconsin, like many other states in the United States, has experienced its share of combustible dust incidents. These combustible dust hazards and incidents pose serious risks to workers, property, and the environment. The State of Wisconsin falls under the Occupational Safety and Health Administration, OSHA, which means that the federal National Emphasis Program on Combustible Dust standard, and the OSHA State Plans applies to this state. Wisconsin is under federal OSHA jurisdiction which covers most private sector workers within the state.

Sources such as the National Fire Protection Association, (NFPA), provide invaluable data on combustible dust incidents. Additionally, platforms like the U.S. Chemical Safety Board, (CSB), archive detailed investigations into major incidents, shedding light on root causes of combustible dust hazards, explosions, and lessons learned. The Dust Safety Science combustible dust incident database provides combustible dust incidents worldwide, including grain dust incidents in Wisconsin.

Combustible Dust and Explosions

Understanding what combustible dust is and why it poses a significant hazard in industrial settings, is a crucial first step in preventing a combustible dust explosion and combustible dust incidents. Combustible dust refers to fine particles or powders that accumulate during manufacturing, the milling process and processing, or grain handling facilities, grain elevators, grain dryers, and operations. These particles can originate from various materials, including metals, plastics, dry corn milling, grains, and chemicals. Combustible dust, such as grain dust, becomes highly explosive when dispersed in the air in high concentrations, causing explosions. Even a small spark or heat source can ignite the grain dust cloud, leading to fire spread, combustible dust hazards, deadly explosions, and a rapid combustion reaction known as a deflagration, causing major property damage. Most processing equipment can’t handle combustible dust hazards.

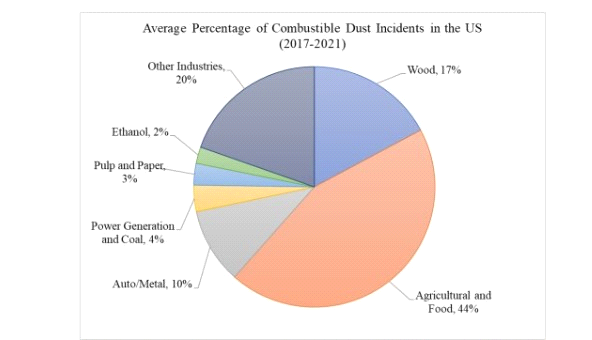

Combustible Dust Incidents

The State of Wisconsin has been grappling with a series of explosive, combustible dust incidents, presenting a concerning trend over the past five years. Over 46 explosions, and incidents have occurred in the State of Wisconsin, in just the last 5 years, according to research from the Dust Safety Science Incident Database. According to the Chemical Safety Board, Dust Safety Science began compiling data on combustible dust incidents in 2016.

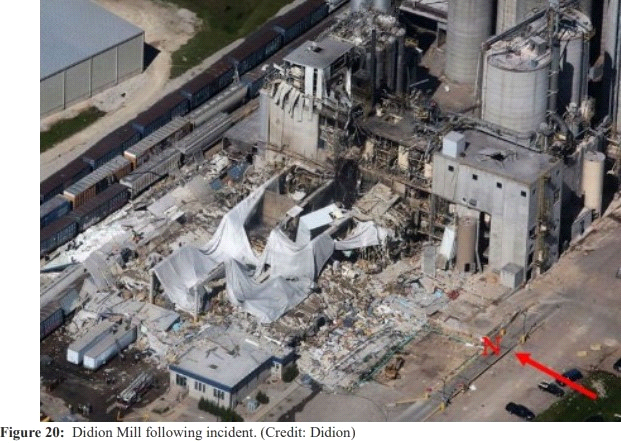

The Didion Milling Company Explosion and OSHA and CSB Results

On May 31, 2017, a grain dust explosion and fire led through the Didion Corn Milling facility and equipment facility in Cambria, Wisconsin. The tragic corn dust incident at Didion Milling Inc in May 2017, resulted in three fatalities and 13 injuries, from the dry corn milling process. Two of the other Didion Milling employees injured later died in hospital bringing the total to five lives lost from the Didion Milling dust explosion. Flame resistant personal protective equipment could have saved other employees lives. Some of the Didion Milling personnel pleaded guilty to the fatal explosion. The Didion Milling food safety and technical superintendent, were convicted of falsifying records, obstructing investigations, and other related charges, endangering workplace safety and environmental protection. The former environmental manager Joseph Winch for conspiring to conceal violations from regulators by falsifying compliance certifications and providing falsified logs, and was sentenced.

On November 11, 2017, OSHA hazard investigation board released their report outlining the safety issues, citations and penalties to Didion Milling facility in Cambria, Wisconsin. Here is the the Occupational Safety and Health Administration, OSHA Summary of Penalties, Citations, and Violations, regarding the Didion Milling Company Explosion and Fire. In addition, a criminal prosecution was led by the US justice department, with fatal dust explosion. Some documents presented to the US justice department were false Clean Air Act compliance certifications, from the operation of air pollution prevention equipment, environmental and sanitation logs and environmental laws.

The Chemical Safety Board released its Final Report regarding the Didion Milling Company Explosion and Fire on December 6, 2023. The Chemical Safety Board, CSB, determined the cause of the Didion Milling explosions and collapsed buildings was igniting combustible corn dust inside milling process equipment and additional mill equipment which transitioned to secondary explosions. CSB hazard investigation board also cited Didion Million for neglect to provide personal protective equipment to employees. As a result, U.S. District Court Judge James D. Peterson for the Western District of Wisconsin sentenced Didion Milling Inc. officials – including a corporate vice president and former food safety, environmental, and operations managers pleaded guilty for their role and falsifying records in a fatal corn dust explosion in May 2017, at a corn mill operated by Didion milling facility in Cambria, Wisconsin.

Building Codes

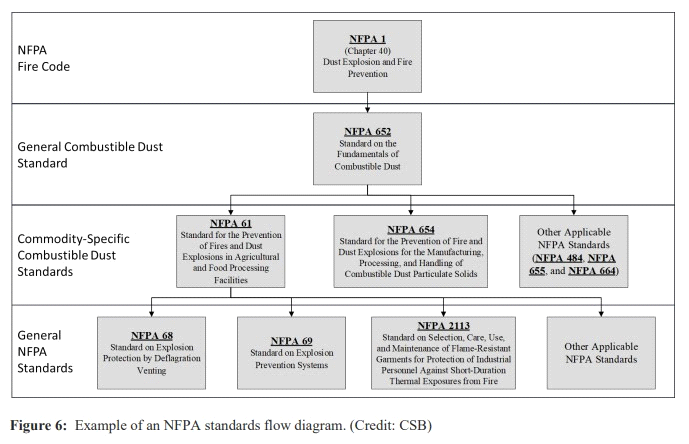

According to the Chemical Safety Board, state building codes regulate the design and construction of building structures within their jurisdiction. The Wisconsin Building Codes can also be researched on the International Code Council website. The Wisconsin building codes are outlined accordingly:

- The IBC incorporates its fire code, which is the International Fire Code (IFC). Chapter 22 of the IFC, Combustible Dust-Producing Operations, incorporates NFPA combustible dust standards by reference. Alternatively, states may choose to adopt NFPA standards directly within the state codes or by reference. Adoption of NFPA requirements is typically via the NFPA 1 Fire Code standard.

- The Wisconsin State Commercial Building Code applies to all commercial and industrial building structures in the state of Wisconsin. Wisconsin applied a state-specific Wisconsin Commercial Building Code before adopting the NFPA, IFC, and IBC standards.

Building Risk Prevention

- Wisconsin Department of Justice, State Fire Marshal: The director of the Arson Bureau within the Division of Criminal Investigation (DCI) serves as the State Fire Marshal. Special Agents and the Special Agent in Charge assigned to the Office of the State Fire Marshal report to the Arson Bureau director, who manages the Office of the State Fire Marshal. Source: https://www.doj.state.wi.us/dci/state-fire-marshal

Root Causes of Incidents

OSHA and the CSB have provided insights into the root causes of combustible dust incidents. Some common factors of workplace safety management systems, and a safety and health complaint include:

- Dust Hazard Analysis, (DHA): The National Fire Protection Association, NFPA 652 Standard requires that the DHA be reviewed and updated every 5 years. A key component of NFPA 652 is the Dust Hazard Analysis, (DHA), a systematic assessment aimed at hazard recognition of combustible dust hazards and implementing appropriate safety measures, and mitigate combustible dust hazards.

- Inadequate Housekeeping: Improper dust cleaning practices and failure to properly clean and maintain combustible dust operations or milling process equipment, can lead to the accumulation of combustible dust. Particulate matter and dust buildup on surfaces, equipment, dust collection equipment, interconnected dust collection systems, and ventilation systems increases the risk of ignition, and fire spread.

- Ventilation Maintenance: Inadequate ventilation systems allow dust particles to remain suspended in the air, creating an environment conducive to explosions.

- Equipment Malfunction: Malfunctioning machinery or equipment can generate sparks or heat, increasing fire spread, and igniting nearby dust accumulations, or the interconnected dust collection systems equipment which can’t handle combustible dust.

- Static Electricity: Static electricity can accumulate on surfaces and materials, especially in dry environments. When discharged, static electricity can ignite combustible dust clouds, leading to explosions. Implementing static control measures and engineering controls, is critical for mitigating this risk, in the immediate vicinity, and to implement safety management systems for static prevention.

- Ignition Sources: External ignition sources, such as open flames, hot surfaces, electrical sparks, and frictional heat, can trigger explosions. Identifying and eliminating potential ignition sources as safety issues are essential for preventing accidents.

Conclusion

Understanding and obtaining knowledge of the combustible dust regulations in Wisconsin is important for safeguarding workplaces, from dust hazards and incidents such as the Didion Milling explosion. In addition, increased awareness and training is required in the grain industry, grain handling facilities, and communities against the risks and poor safety culture, posed by these combustible dust hazards and hazardous materials. By adhering to federal Occupational Safety and Health Administration, OSHA combustible dust standard, the National Fire Protection Association standards, as well as state-specific regulations overseen by the Wisconsin Department of Safety and Professional Services (DSPS), employers can ensure compliance, engineering controls, emergency preparedness, workplace safety and health, safety management systems, and mitigate the potential for combustible dust incidents.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust Incidents in Wisconsin information, with this Podcast Link: Plastic Dust Collector Fire in Sheboygan, Wisconsin

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art fire and explosion protection.