Updated December 12, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A picture of a Combustible Dust Fire and Hazard, and bags of Grain, inside a Grain Manufacturing Facility

Key Takeaways:

- Industry Dynamics: The grain and agriculture industry along with feed mills, play a pivotal role in global food production and supply. However, this multifaceted sector also harbors an often-overlooked dust hazard: combustible grain dust, and grain dust explosions, derived from the processing and handling of grains and agricultural materials like wheat, corn, barley, and rice.

- Hazards of Combustible Dust: Combustible grain dust, prevalent in grain facilities, poses a significant safety and health risk due to its inherent flammability. Factors such as fine particulate nature, dust suspension in a confined area, dust clouds, and susceptibility to ignition sources contribute to the potential for dust hazards, grain dust explosions, or fire.

- Specific Concerns: Grain bins, essential for storing harvested crops, represent a key concern due to the potential for smoldering incidents leading to combustible grain dust accumulation, dust clouds or grain dust explosions. Equipment used in handling and processing, such as conveyors and dryers, contributes to dust generation and increases the risk of mechanical sparks, elevating the hazard level, and grain dust explosions.

Understanding the Combustible Dust Hazards in the Grain and Agricultural Industries

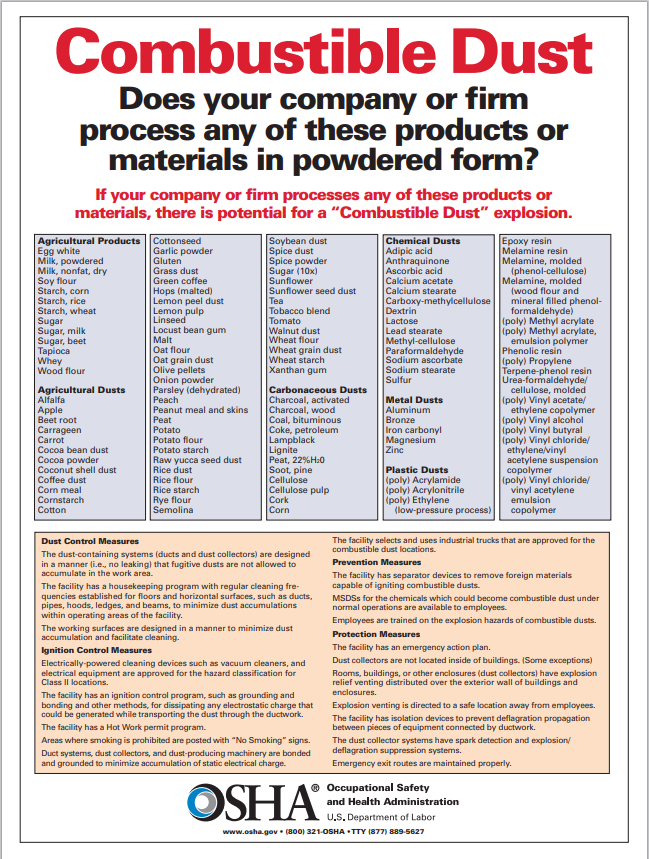

The grain and agriculture industry stands as an indispensable cornerstone of our global economy, providing sustenance to populations worldwide and serving as a linchpin for various industries. The Occupational Safety and Health Administration, (OSHA), identifies Grain as a Combustible Dust. Fine particles generated during various stages of grain and agricultural processing, and feed mills, such as mixing, drying, and transporting, constitute the primary source of combustible dust in these facilities. This multifaceted sector encompasses the cultivation, harvesting, processing, and distribution of grains, cereals, oilseeds, flours, and other agricultural commodities. It not only fuels the food supply chain but also contributes significantly to biofuels, animal feed, and various industrial products. However, within this industrious domain lies a hidden safety and health risk—a potential hazard that has garnered increased attention over the years: combustible dust suspended in air as dust clouds, and how grain dust explosions occur. According to Oklahoma State University Extension, OSHA regulations for grain elevators require that grain dust not exceed a 1/8-inch depth within 35 feet of a bucket elevator. Keeping grain dust depths at less than 1/8-inch deep on any working floor of an elevator generally would not keep that facility below the MEC. The MEC concentration of 0.05 ounces per cubic foot, 50 grams per cubic meter, is more than three times the OSHA standard for worker exposure 15 grams per cubic meter.

In the grain and agriculture industry, the presence of combustible dust represents a significant peril, creating grain dust explosions. This fine particulate matter is often a byproduct of processing and handling grains or agricultural materials like wheat flour, grain flour, corn, corn starch, oat flour, barley, and rice, and is inherently combustible, and how grain dust explosions and secondary dust explosions occur. The nature of these materials, when finely ground, such as flour, during various processing stages or stored in silos, or a confined area, elevates the risk of dust hazards, grain dust explosions, and secondary dust explosions. These particles, when suspended in the air in certain concentrations, as a dust cloud, can ignite swiftly when exposed to an ignition source, like electrical wires, triggering grain dust explosions or fires with devastating consequences. This dust, composed of organic materials, possesses the potential for rapid combustion when exposed to ignition sources, such as static electricity, setting the stage for combustible grain dust explosions, possible grain dust explosions or fires within a dust bin, feed mills, grain processing facilities, silos, or storage areas. In addition, if coal is being used as a power source at an agriculture or food processing facility, then there is also a potential for coal dust explosions from coal dust. This situation could create a hybrid mix of combustible material and hazardous materials, and many potential dust explosion hazards, with grain dust and coal dust.

The fine, granular composition of these materials facilitates the dispersion and suspension of grain dust particles, as dust clouds, suspended in air, increasing the likelihood of their interaction with ignition sources such as electrical equipment, friction, sparks, or even static electricity. As grains are processed and handled—whether through milling, grinding, conveying, or storage—a considerable amount of grain dust is produced, along with airborne dust clouds. This combustible material and dust, when allowed to accumulate, creates an environment ripe for grain dust explosions. Factors like particle size concentration in the air, and the presence of oxygen concentration contribute to the combustibility of this dust, emphasizing the critical need for dust control, and stringent safety protocols and preventive measures, from a possible grain dust explosion. In addition, the control of grain dust emissions is required by the U.S. Clean Air Act of 1990 and the Oklahoma Clean Air Act of 1991. Mitigation of explosions, can be enforced and requires dust safety training. Any fire needs three elements. These elements are known as the “fire triangle”: 1. Fuel to burn 2. Oxygen 3. Ignition source. The four basic elements must be present for a grain dust explosion to occur are fuel, oxygen, confinement, and an ignition source. Confinement is the final element creating what is known as the dust explosion Pentagon.

- Fuel: dust particles from wheat, oats, barley, or other types of grain that are suspended in the air or layers of grain dust in a confined area

- Oxygen: normal oxygen levels and a continuous air supply

- Confinement: areas of confined area such as grain bins, basement tunnels, bin deck galleries, silos, downspouts, belt conveyors, and enclosed drag conveyors

- Ignition source: short circuits, static electricity, electrical equipment, electrical arc, lit cigarettes or cigarette lighter, overheated bearings, friction, cutting torches or welding devices, grinder sparks, lightning, and so on

Moreover, the confined areas inherent in grain storage facilities and processing plants exacerbate the combustible grain dust explosion hazard. Grain silos and grain elevators, the standard equipment of the industry, provide an enclosed or confined space environment where accumulation of combustible dust can occur unnoticed, catch fire, and create an explosion hazard. The combination of combustible dust, and dust particles in a confined space, and potential ignition sources, such as grain elevators, and normal oxygen levels, increases the chance for free grain dust recirculating, and potential grain dust explosions, and poses a considerable safety and health risk to workers, as well as for integrated pest management (IPM) purposes, infrastructure, and surrounding communities. Understanding these specific challenges is pivotal for implementing proactive strategies to mitigate the potential hazards posed by combustible dust in the grain and agriculture sectors, preventing grain dust explosion conditions and secondary dust explosions.

A picture of the NFPA 61 Guide and the NFPA 61 Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

The Grain and Agriculture Industry Specific Concerns and Root Causes with Combustible Dust

Within the grain and agriculture industry, specific equipment and operational procedures can exacerbate the risks associated with combustible dust and grain explosions. Grain bins, vital structures for storing harvested crops, present a notable concern due to the potential for smoldering incidents. When grains are stored in bulk, heat generated by microbial activity or chemical reactions within the stored material can lead to spontaneous combustion. This smoldering process, and heat source, if undetected or unmanaged, can catch fire and accelerate and contribute to the accumulation of combustible dust, augmenting grain dust explosion elements, and secondary grain explosions, within the storage facility. Temperature monitors can be assistive, in preventing this type of combustion, and explosion hazard.

Moreover, the handling and processing equipment used in grain facilities, such as grain elevators, bucket elevators conveyors, belt conveyors, grinders, separators, and dryers, can generate significant dust as a byproduct, requiring dust collection and a grain and dust cleanout. Installing dust aspiration systems or a ventilation system at grain handling transfer points is a preventative measure. Dust aspiration systems, also known as dust extraction or dust collection systems, remove dust and other particles from the air to create a safer and cleaner work environment. According to the OSU Extension, examples of two ignition, preventive grain dust explosion measures are: belt rub sensors installed inside bucket elevator leg casings to detect belt misalignment to prevent friction heating. Replace steel cups with plastic cups in elevator legs. The intricate machinery involved in these operations increases the risk of friction, and mechanical sparks, or a possible electrical short, which, when combined with the combustible dust suspended in the air, as suspended dust particles and airborne dust, heightens the potential for grain explosions and catastrophic primary and secondary explosions, creating a chain reaction and series of explosions, like rolling thunder, as a destructive force.

Combustible dust is a serious workplace hazard that can lead to catastrophic incidents if not properly managed. To mitigate the risks associated with combustible dust, various standards and regulations have been put in place. The Occupational Safety and Health provided a special combustible dust bulletin with grain handling mentioned. A Dust Hazard Analysis DHA, should also be performed and documented. A Dust Hazard Analysis (DHA), is a systematic review to identify and evaluate the potential flash fires, or combustible dust explosion hazards, such as a dust cloud associated with the presence of one or more combustible particulate solids in a process or facility, NFPA 652-19. The goal of a combustible Dust Hazard Analysis is identifying and mitigating dust hazards such as combustible dust fires, and combustible dust explosion hazards that pose a risk to people and property. A Dust Hazard Analysis DHA can uncover the risk of combustible dust hazards and combustible dust explosions, from combustible particulate solids forming a dust cloud. Identifying explosion hazards and dust explosion prevention in a Dust Hazard Analysis, DHA is paramount to establishing comprehensive safety measures.

In the year 1923, was when the NFPA published the first standard on combustible dust, as no national regulations were enacted to address the problem of combustible dust directly, and grain dust explosions and fires, along with loss of life and property, continued to occur. Listed are the important combustible dust standards and regulations, and why they are crucial for the safety and health of workers and the prevention of industrial disasters:

- NFPA 61, Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities NFPA 61 protects lives and property from fires and explosions in facilities handling, processing, or storing bulk agricultural materials, their by-products, or other agricultural-related dust and materials.

- NFPA 68, Standard on Explosion Protection by Deflagration Venting applies to the design, location, installation, maintenance, and use of devices and systems that vent the combustion gases and pressures resulting from a deflagration within an enclosure or confined area, so that structural and mechanical damage is minimized. Chapter 8 of the NFPA 68 provides guidance on Venting of Deflagrations of Dusts and Hybrid Mixtures, Effects of Vent Ducts, Bins, Hoppers, and Silos, Venting of Dust Collectors Using Bags, Filters, or Cartridges, Bucket Elevators, Venting Internal to Building with Flame-Arresting and Particulate Retention Device, Venting Silos or Other Storage Vessel Provided with Integral Bin Vents, and Deflagration Venting of Enclosures Interconnected with Pipelines.

- NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids. The NFPA 654 Standard is referenced by OSHA’s Combustible Dust National Emphasis Program (NEP) to identify dust hazards and define mitigation strategies that help protect life and property. The standard provides industry-recognized explosion hazard and safety practices for facility and systems design, dust collection systems, electrical equipment, process equipment protection, fugitive dust control and controlling grain dust emissions, good housekeeping, ignition source identification and control, fire protection, training and procedures, inspection, and maintenance. Annexes offer guidance on the application of area electrical classification for various accumulation of dust levels, to prevent a primary explosion.

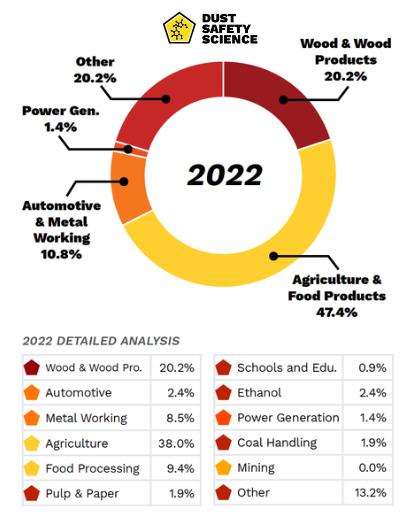

A picture of a detailed analysis and percentages of several Industries, including Grain and Agriculture and Food Products, affected by Combustible Dust, from Dust Safety Science

Historic Grain and Agriculture Industry Combustible Dust Explosions

Combustible dust incidents and combustible dust explosions happen worldwide, in the Grain and Agriculture and Agribusiness industry, as presented in this combustible dust research and incident database from Dust Safety Science. In addition, statistics of the most prevalent industries, regarding combustible dust incidents, are also captured in this Annual Incident Report Database, from Dust Safety Science. Over the past decade, an average of 7.8 agricultural grain dust explosions were reported per year in the United States, according to statistics from Purdue University. During 2022, the Grain and Agriculture dust occurred in 38% of combustible dust incidents. In addition, the Dust Safety Science Podcast educates the public on Safety Share – Explosion at Wood Pellet Receiving Port. Some of the historic Grain and Agriculture Industry combustible dust explosions, grain explosions, and incidents include:

- The Great Mill Disaster (1878): Also known as the Washburn A Mill explosion, occurred on May 2, 1878, in Minneapolis, Minnesota, United States Two professors from the University of Minnesota, S. F. Peckham, and Louis W. Peck, later confirmed that abundant flour dust had been the cause of the explosion after reviewing controlled experiments regarding flour dust combustion They concluded that two dry millstones had rubbed against each other and caused a spark that ignited the dust, causing the primary explosion.

- According to the NFPA, the Year 1919 was especially trying. On May 20, a blast at a feed grinding plant in Milwaukee, Wisconsin, destroyed the facility and killed three people. Two days later, in Cedar Rapids, Iowa, an immense explosion, one reportedly felt 30 miles away, such an explosion, leveled the Douglas Starch Works, killing 43 and injuring 30. In September, a large grain elevator in Kansas City, Missouri, exploded, killing 14 and injuring 10. In all of these incidents and many more, dust was identified as the culprit. Source: NFPA Journal A Century of Dust

- The Murray Grain Elevator Explosion of 1919: The Murray Grain Elevator was torn apart by an explosion on September 13, 1919, fourteen men were killed and 10 seriously injured. The elevator failed two inspections in the same month and was pronounced ‘dangerous’ both times. After inspecting the damage and interviewing witnesses, they concluded that the explosion and flash fire originated in the basement. The flash fire and explosion propagated up through the man lift tower on the side of the elevator and blew out the lower level walls with unusually aggressive force. Pieces of the 16-inch concrete wall were found dozens and, in some cases, hundreds of feet from the site, and the entire working shed was blown away, leaving a demolished grain dryer behind.

Historical incidents of combustible grain dust explosions within the grain and agriculture industry provide the continuous grain dust explosion risks inherent in this vital sector. From grain silos, and grain elevators to processing facilities, these grain handling and grain dust incidents have highlighted the devastating consequences of combustible dust accumulation, stored grain, grain dust emissions, grain dust emission control, and ignition. Each major grain explosion serves as a stark reminder of the need for continuous grain dust control, dust explosion prevention, safety, health vigilance, and robust safety protocols. Training employees and proactive risk management strategies are required for dust explosion prevention, preventing a dust cloud, a flash fire, and a major explosion, and future primary and secondary explosions, and grain dust explosions worldwide.

Conclusion

Combustible dust and grain explosion incidents, and dust hazards continue to pose significant risks worldwide, particularly in industries such as Grain and Agriculture and Agribusiness. The data compiled in the Dust Safety Science research and incident database sheds light on the prevalence and severity of these grain handling and grain dust explosion incidents, with the Grain and Agriculture Industry accounting for 38% of reported incidents in 2022. Additionally, historic and major dust explosion events such as the Great Mill Disaster of 1878 and the Murray Grain Elevator Explosion of 1919 serve as poignant reminders of the catastrophic consequences of combustible grain dust mishaps. These grain handling and grain dust incidents underscore the critical importance of inspecting grain dust accumulating in processing areas, proactive health administration and safety measures, ongoing education to prevent future combustible dust explosion tragedies, and a major dust explosion, including primary and secondary explosions. Simple safety changes, such as substituting steel cups with plastic cups in elevator legs, and installing belt rub sensors inside bucket elevator leg casings, can provide quick safety measures, from combustible dust hazards.

Through incident analysis, it becomes evident that factors such as grain dust accumulation, confined areas, equipment malfunction, and ignition sources contribute to a flash fire and the occurrence and severity of these incidents. Confinement is the final element creating what is known as the dust explosion Pentagon, and increases the risks of secondary explosions. Resources such as preventing grain dust explosions, from Oklahoma State University Cooperative Extension Service, and the National Fire Protection Association, are extremely beneficial. Amidst the grain dust explosion statistics, there is hope in the form of education, lessons learned, dust explosion prevention, and preventive measures implemented. A Dust Hazard Analysis DHA can uncover the risk of combustible dust hazards and combustible dust explosions, from combustible particulate solids forming a dust cloud. Industry-wide initiatives, preventive maintenance, improved equipment design, enhanced ventilation systems, and comprehensive training programs have all played pivotal roles and top priorities, in mitigating the grain dust explosion risks associated with combustible grain dust in the grain and agriculture industry.

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible in the Grain and Agriculture Industry, visit this podcast episode: Typical Hazards in Grain Milling, Sifting, and Sorting Applications With Matt Williamson and Case Study – The Murray Grain Elevator Explosion of 1919

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.