Updated December 4, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is the DeBruce Grain Elevator Dust Explosion?

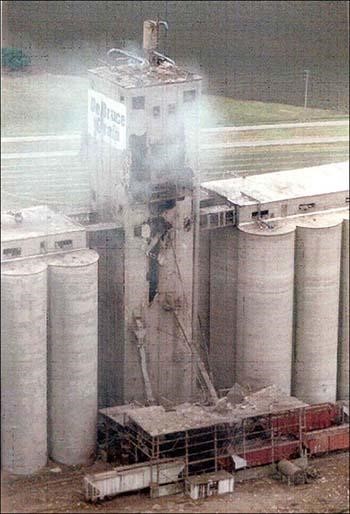

The DeBruce Grain Elevator explosion on June 8, 1998, remains one of the most significant industrial disasters in the agricultural sector. Located in Wichita, Kansas, the DeBruce Grain Elevator was, at the time, one of the largest grain storage facilities in the world. This catastrophic event, resulting from a grain dust explosion, highlights the critical importance of safety measures in grain handling operations, with grain dust control systems, and suspended grain dust. On that fateful day, a series of explosions and the blast wave traveled through the DeBruce Grain Elevator, resulting in the deaths of seven workers and injuring ten others. The explosions were so powerful that they caused extensive structural damage to the facility, leading to significant financial losses and highlighting severe safety deficiencies. According to the Occupational Safety and Health Administration, OSHA, Grain Elevator Explosion Investigation Team, (GEEIT), the Federal Emergency Management Agency sent 20 trained searchers and 42 support personnel to help local rescue crews with the Debruce grain incident.

What Caused the DeBruce Dust Explosion

According to OSHA, The DeBruce Grain Elevator explosion was primarily caused by a series of additional explosions of increasing severity, which occurred when grain dust was ignited in the east tunnel of the south array of silos. The most probable ignition source of the initial explosion and blast wave, was created when a concentrator roller bearing, which had seized due to no lubrication, caused the roller to lock into a static position as the conveyor belt continued to roll over it. This “razor strop” effect on the roller raised its temperature to 260oC, well beyond the 220oC required to ignite layered grain dust which was plentiful inside the roller.

Previous Accidents at the DeBruce Grain Elevator

Several workers had died in this elevator throughout its history before the 8 June 1998 Debruce grain explosion. For example, during confined space entry work in 1978 and 1983, two workers died while treating badly injured survivors. The 1983 death resulted in both an OSHA investigation of the death as well as an inspection of the elevator. This was the last time OSHA had visited this elevator until the explosion.

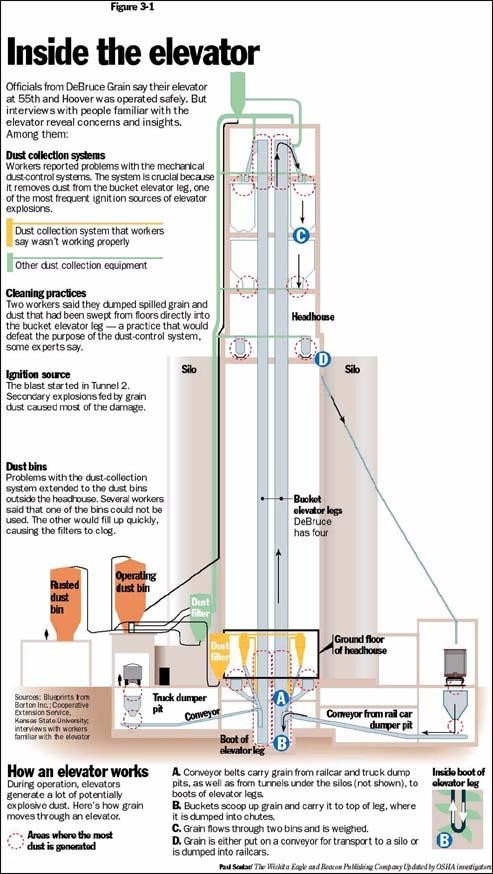

The Chimney Effect and Its Role

The design of the DeBruce Grain Elevator also played a significant role in the disaster. The structure’s vertical design created a “chimney effect,” where hot gases and grain dust could easily rise through the building. This effect exacerbated the spread of the explosion, causing more extensive damage.

OSHA and NFPA Safety Measures and Regulations

In response to such incidents, OSHA has established comprehensive guidelines for grain handling facilities. These guidelines emphasize the importance of proper housekeeping, dust control, and regular maintenance of equipment. The OSHA Grain Handling Safety standards outline specific requirements for managing combustible dust, and elevator structure, including the implementation of dust collector systems and controlling ignition sources.

The Occupational Safety and Health Administration, OSHA, sets forth regulations related to grain handling facilities in the United States. These regulations, outlined in OSHA’s Grain Handling Facilities Standard (29 CFR 1910.272), cover requirements for:

- Housekeeping: Mandating regular cleaning to control dust accumulation.

- Grain Dryer Safety: Establishing guidelines for the safe operation of grain dryers.

- Preventative Maintenance: Requiring regular inspection and maintenance of equipment.

- Emergency Planning: Ensuring facilities have emergency action plans in place.

The National Fire Protection Association, NFPA, provides guidelines for the prevention of dust explosions in agricultural and industrial settings. NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities, includes recommendations for:

- Dust Control: Implementing measures to minimize dust generation and accumulation.

- Ignition Source Control: Identifying and mitigating potential ignition sources.

- Explosion Protection: Installing explosion protection systems to mitigate the impact of explosions.

The Impact on Industry Practices

Since the DeBruce explosion, there has been a heightened focus on improving safety standards in the grain industry. Facilities are now more vigilant in implementing dust control measures and adhering to safety regulations. The disaster prompted significant changes in industry practices, including the design of grain elevators such as the grain elevator at the Garvey Grain Company, to minimize the chimney effect and the use of explosion-proof equipment.

What is Combustible Dust

The National Fire Protection Association, (NFPA), defines combustible dust as “a combustible particulate solid that presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape.”

Combustible particulates with an effective diameter of 420 μm or smaller are generally considered combustible dust. The vast majority of natural and synthetic organic materials, and some metals, can form combustible dust. The NFPA’s Industrial Fire Hazards Handbook states, “Any industrial process that reduces a combustible material and some normally non-combustible materials to a finely divided state presents a potential for a serious fire or explosion.”

Combustible dust refers to fine particles that, when suspended in the air, can ignite and cause explosions. Common examples of combustible dust include flour, sugar, and wood dust. These materials are often harmless in bulk form but can become hazardous when finely divided and dispersed in the air.

What Causes a Dust Explosion?

Combustible dust refers to fine particles suspended in the air, capable of igniting under certain conditions, leading to fires or dust explosions. When these particles accumulate on surfaces and suspended ceilings and encounter an ignition source, the resulting dust explosion and blast wave can be devastating. These airborne particles can ignite with a spark or flame, leading to combustion and potentially causing a fire or dust explosion.

Other materials and products, such as grain dust, flour, paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are not combustible in larger pieces but can be when pulverized to fine dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials. Various materials can produce combustible dust. Some common combustibility examples include:

- Metals: Aluminum, magnesium, titanium

- Organic materials: Wood, grain, sugar, flour

- Chemicals: Pharmaceuticals, certain plastics, coal

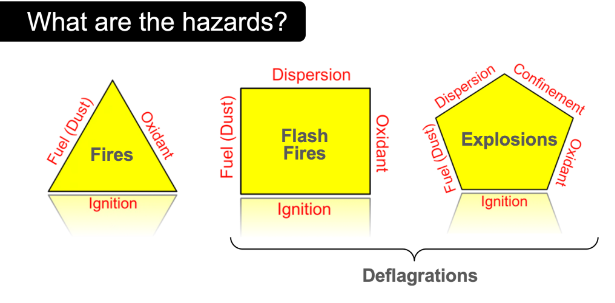

The Dust Explosion Pentagon

The Dust Explosion Pentagon illustrates the five elements necessary for a dust explosion:

- Fuel: Combustible dust particles.

- Oxygen: Present in the air.

- Heat Source: An ignition source like a spark, hot surface, or flame.

- Dispersion: Dust particles must be suspended in the air.

- Confinement: The dust and or dust cloud must be within an enclosed or semi-enclosed space.

Removing any one of these elements can prevent a dust explosion.

Combustible Dust Explosion Prevention

Preventing combustible dust explosions requires a multi-faceted, strategic approach:

- Housekeeping: Regular and Safe cleaning methods to prevent dust accumulation.

- Dust Collection Systems: Installing dust collector systems to capture and contain dust.

- Ignition Control: Eliminating or controlling potential ignition sources.

- Dust Hazard Analysis: (DHA), is a systematic review to identify and evaluate the potential fire, flash fire, or explosion hazards associated with the presence of one or more combustible particulate solids in a process or facility (NFPA 652-19).

Conclusion

The DeBruce Grain Elevator explosion is a tragic reminder of the potential dangers in grain handling facilities. By understanding the causes and implementing stringent safety measures, the industry can prevent such disasters in the future. Continuous vigilance, adherence to regulations, and a commitment to safety are essential to protect workers and ensure the safe operation of grain handling facilities, preventing a loud explosion. By learning, from past incidents such as the Debruce grain incident, and continuously improving safety practices, a safer working environment will be created for everyone in the grain handling industry.

Additional References:

National Fire Protection Association (NFPA): Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

OSHA Grain Handling Safety: Comprehensive guidelines and regulations for grain handling facilities.

EPA Superfund Site Information: Detailed reports on environmental impacts and investigations.

Dust Safety Science: Dust Explosion Hazards in the Grain and Agriculture Industries

Wikipedia: Grain Elevator: General background information on grain elevators and their operation.

About Dust Safety Science

For more from Dr. Chris Cloney on Grain Explosions, visit this Podcast: Case Study – Grain Dust Explosion in a Milling Facility

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.