Updated April 10, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A combustible dust explosion happens when finely divided solid particles suspended in the air ignite, causing a rapid and intense blast. Learn about its causes, risks, and effective prevention methods to keep your workplace safe.

A combustible dust explosion happens when tiny dust particles—like wood, metal, sugar, or grain—mix with air and catch fire. Common causes include sparks, hot surfaces, and static. Industries like factories, farms, and mining are at high risk.

To prevent explosions, businesses must clean dust often, improve airflow, use safe tools, and control ignition sources. By understanding the risks and using safety steps, companies can protect workers and prevent costly accidents.

Key Takeaways:

-

- Lethal Threat: Dust explosions represent a lethal and often underestimated hazard in various industries, including manufacturing, agriculture, and energy production.

- Regulatory Framework: Regulations, standards, and practices for mitigating dust explosions vary globally, making it imperative for organizations to understand and adhere to regional guidelines for combustible dusts.

- Modern Innovations: Tools and technologies for monitoring and preventing an explosion have evolved, offering comprehensive solutions that encompass risk assessment, real-time monitoring, and rapid response systems for combustible dust as an explosion hazard.

- International Perspective: International case studies provide valuable lessons, demonstrating the consequences of neglecting safety measures and highlighting the benefits of international harmonization in safety standards for combustible dust and explosions.

- Cultural and Organizational Factors: The culture of safety within an organization and adherence to compliance are key determinants in preventing dust explosions.

Need answers? Our experts are ready to help—click for support!

Table of Contents:

-

- What are Combustible Dust Explosions?

- The Science Behind Combustible Dust Explosions

- Industries Most Affected by Combustible Dust Explosions

- Historical Dust Explosions Incidents and Lessons Learned

- Prevention and Mitigation Techniques for Dust Explosions

- Tools and Technologies for Monitoring and Prevention of Dust Explosions

- Conclusion

- Recommendations for Further Reading and Resources

What are Combustible Dust Explosions?

Explosions from combustible dust are violent and often devastating events that occur when fine, dry particles of combustible materials and explosive dust become suspended in air and then ignite, leading to a rapid release of energy and a primary explosion. Key elements necessary for such an explosion include fuel (the dust), oxygen (present in the air), and an ignition source (typically a spark, open flame, or even hot surfaces).

The sequence of events leading to an explosion involves the dispersion of combustible dust particles in the air, the formation of a dust cloud, ignition, and the subsequent rapid combustion of the combustible dust cloud, resulting in pressure waves, fireballs, and potential damage. The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations”.

Historical Context:

The history of combustible dust fires, dust explosions, and combustible material is marred by numerous catastrophic incidents. During the 18th and 19th centuries, industries of grain milling, flour, and textiles experienced devastating grain dust explosions and a possible flour dust explosion. Giacomelli’s Bakery Warehouse (1785): According to historical accounts from The Repertory of Arts and Manufactures, Volume 2, Publisher G. & T. Wilkie., 1795 Original, from the New York Public Library, Digitized Aug 19, 2011, Count Carlo Ludovico Morozzo di Bianzè investigated and recorded December 14th, 1785. The flour dust explosion occurred when one worker was pouring flour into a bolter from a second floor level of the bakery.

The Washburn “A” Mill explosion in 1878 in Minneapolis, Minnesota, is a notable example, where a grain dust explosion killed 18 workers. Later on, in June 1998, the largest debruce grain elevator at the time suffered the tragic consequences of a grain dust explosion, with accumulated dust, in a grain elevator.

Throughout the 20th century, industries such as mining, woodworking, and food processing continued to grapple with dust hazards, fires and dust explosions. The Benxihu Colliery explosion in China in 1942, one of the deadliest coal explosions in history, claimed over 1,500 lives.

Relevance in the Modern Era:

Combustible dust hazards remain a significant concern in the modern era. A wide range of industries, including agriculture, metalworking, pharmaceuticals, and chemical processing, generate dust as a byproduct of their operations. These industries face the ongoing challenge of managing the risks associated with dust.

In response to the dangers posed by combustible dust, various safety regulations and standards have been developed worldwide. In the United States, the OSHA and the National Fire Protection Association (NFPA) have issued guidelines and standards, such as NFPA 652, to help industries prevent and mitigate explosions.

Modern technology and research have also contributed to better understanding and managing combustible dust risks, with fires and explosions. Advanced combustible dust collection and suppression systems, along with training programs for personnel, have become essential components of preventing dust-related incidents.

Combustible dust hazards have a long history of causing harm, and they continue to be a relevant concern in the modern industrial landscape. As long as combustible dust and combustible materials are present in various industries, businesses and regulatory authorities to remain vigilant and proactive in addressing the fires and explosions risks associated with combustible dust to ensure the safety of workers and the public.

The Science Behind Combustible Dust Explosions

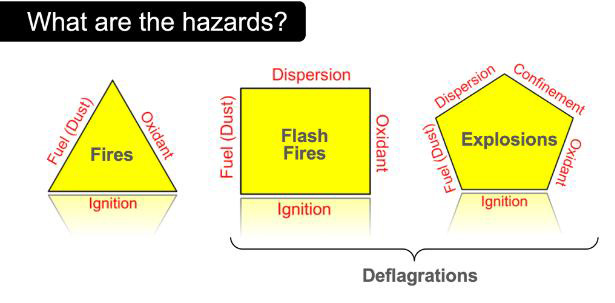

The scientific principles underlying explosions include the detailed breakdown of the combustion process, the factors that influence explosions, and key concepts such as Minimum Ignition Energy (MIE), Minimum Explosible Concentration (MEC), particle size, and others. The fire triangle starts with fuel, oxygen, and an ignition source. So if you have these three elements at the same time, in the right concentration, you can get a fire. The dust explosion pentagon is an expansion of the fire triangle as it relates to combustible dust.

An explosion can be thought of as a “violent and destructive shattering or blowing apart of something” and a chain reaction. In order to have an explosion, there must be confinement of the flame propagating in the dust-air mixture.

Confinement is the final element making up the dust explosion pentagon. With confinement of the propagating flame front, pressure will rise, which may cause rupture of the enclosure, which describes the dust explosion pentagon, and may lead to secondary dust explosions.

Detailed Breakdown of the Combustion Process: Explosions follow a sequence of events that can be understood as a complex chemical reaction and how they have the ability to catch fire and explode as dust:

Fuel: Fine particulate matter, fine particles, and very small particles, such as dust or powdered materials, serve as the fuel. In dust form, combustible dust can originate from various sources, including wood, metals, plastics, chemicals, and organic materials, and have a various particle size, and energy concentrations.

Oxygen: The oxygen in the air acts as an oxidizer, required for combustion to occur.

Ignition Source: An ignition source, which can be a spark, static electricity, open flame, hot surface, friction, or electrical discharge, initiates the combustion process.

Dust Suspension: Combustible dust particles become suspended in the air, forming a dust cloud. The concentration of dust in the cloud, suspended in air, must be within a specific range to support an explosion hazard when the dust explosion occurs.

Ignition: Combustible dust explosions happen when the dust cloud encounters an ignition source, such as static electricity, causing the combustion of the suspended dust particles.

Rapid Combustion: The combustion propagates throughout the dust cloud at an astonishingly high rate, generating pressure waves and fireballs, leading to an explosive release of energy.

Factors Influencing a Dust Explosion (Fire Triangle for Dust):

The three elements and factors that influence explosions under certain conditions can be conceptualized using a “Fire Triangle” analogy, which includes these three key elements:

Fuel (Combustible Dust): The type and properties of the combustible dust play a significant role in the likelihood of an explosion. Factors such as particle size, shape, chemical composition, and moisture content affect the explosiveness of the combustible dust.

Oxygen (Air): The availability of oxygen in the air, often expressed as oxygen concentration or some other oxidizing medium, must be within a specific range to support combustion. Insufficient or excess oxygen can inhibit explosion propagation.

Ignition Source: The presence of an ignition source is critical. Common sources include electrical equipment, welding operations, friction from moving machinery, and hot surfaces. Preventing or mitigating potential ignition hazards is a key safety measure with combustible dust.

Key Terms and Concepts:

Minimum Ignition Energy (MIE): MIE is the minimum amount of energy required to ignite a dust cloud when the air-fuel mixture is within its explosible range. It is typically measured in millijoules (mJ).

Minimum Explosible Concentration (MEC): MEC is the lowest concentration of combustible dust in the air that can support a dust explosion when an ignition source is present. Below this right concentration, the mixture is too lean to explode; above it, the mixture is too rich.

Dust Cloud Flammability Limits: These limits define the range of dust concentrations in which an explosion can occur. The lower explosive limit (LEL) and upper explosive limit (UEL) are specific concentrations below and above which explosions cannot occur.

Dust Deflagration: A dust deflagration is a rapid combustion of dust that propagates at subsonic speed, generating pressure and flash fire but not a shockwave.

Dust Detonation: A dust detonation is a supersonic combustion that produces shockwaves, leading to more destructive explosions. These are uncommon in most industrial processes but may be possible in coal mining applications.

Understanding the science behind explosions, along with these key terms and concepts, is crucial for industries that handle combustible materials.

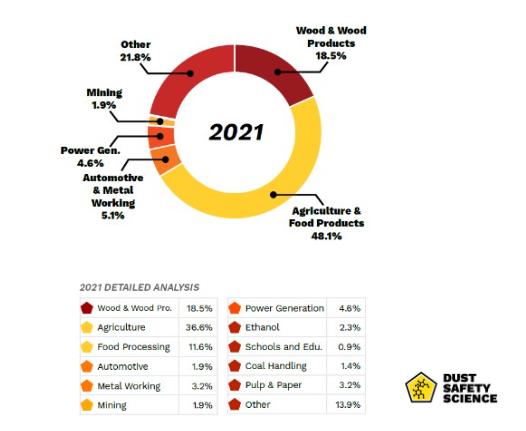

Industries Most Affected by Dust Explosions

Overview of Sectors with Heightened Risks: Some of the industries with explosions include:

Agriculture and Food Processing: Industries dealing with grains, cereals, and agricultural products are particularly susceptible to explosions. Flour mills, Silos, milling facilities, food processing, and agricultural products manufacturing processes plants often create fine particles and conditions conducive to grain dust explosions. Grain handling is a cornerstone of both agriculture and food industries, serving as the initial step in processing grains like wheat, oats, barley, and more. However, this essential process includes hazards, chief among them being grain dust explosions. An average of 10.6 agricultural grain dust explosions are reported per year in the U.S., resulting in 1.6 deaths, 12.6 injuries, and millions of dollars in damages (Schoeff, 2006). Historically, grain dust explosions have caused significant damage and loss of life. One of the most infamous examples is the grain dust explosion at the DeBruce Grain elevator in Kansas in 1998, where six workers lost their lives due to a massive blast triggered by the ignition of grain dust. Over the past decade, an average of 7.8 agricultural grain dust explosions were reported per year in the United States, according to statistics from Purdue University. Grain explosions are rapid combustion reactions fueled by the ignition of suspended particles in the air. These grain dust explosions occur when finely ground particles of grain dust, or wheat flour, typically generated during handling and processing operations, or in flour mills, grain silos, bucket elevators, grain elevators, or in a grain storage facility, become suspended in the air at concentrations within a specific range known as the minimum explosive concentration (MEC). When an ignition hazard, such as a spark or flame from a grain elevator, comes into contact with this combustible dust cloud, it can result in a devastating primary explosion and lead to a catastrophic secondary explosion. Such incidents underscore the urgent need for preventive measures and safety protocols in flour mills, grain facilities, bucket elevators, grain elevators, and confined spaces to prevent grain dust explosions.

Woodworking and Sawmills: Wood dust, generated from cutting, sanding, and processing wood, can lead to hazardous airborne dust and dust clouds. Woodworking shops, lumber mills, and furniture manufacturing are at risk.

Metalworking: Metal dust, generated during grinding, cutting, and polishing, can ignite and explode. Metalworking facilities, metal processing, and metal recycling operations, including foundries and machining shops, must manage the risk of metal dust explosions.

Chemical and Pharmaceutical Manufacturing: Chemicals and pharmaceuticals can produce combustible dust, especially when they are in powdered form, including chemical dust. Ensuring safe handling and storage is vital in the chemical manufacturing industry.

Plastics and Rubber Industries: These industries produce fine dust during processing and molding. Explosions can occur in plastic and rubber manufacturing facilities, making dust control crucial.

Textile Mills: The textile industry generates significant finely divided dust from fibers and dyes. Cotton, wool, and synthetic materials can all contribute to dust risks.

Energy and Utilities: Power plants, particularly coal-fired ones, can experience coal dust explosions. Finely divided dust generated from the handling and transportation of coal as a solid material poses significant risks.

OSHA Guidelines for Combustible Dust

The OSHA gives comprehensive guidelines to manage combustible dust hazards in the workplace. However, OSHA implements safety through the General Duty Clause of the OSH Act of 1970 and other standards. These are the key elements:

1. Definition and Examples

Combustible dust are fine particles that can cause an explosion hazard when they’re suspended in air under specific conditions. Common examples are wood, grain, plastics, chemicals, pharmaceuticals, metals, and coal.

2. Applicable Standards

While there isn’t any combustible dust standard, OSHA uses these to address dust hazards:

- 29 CFR 1910.22 (Housekeeping)

- 29 CFR 1910.94 (Ventilation)

- 29 CFR 1910.147 (Lockout/Tagout)

- 29 CFR 1910.178 (Powered industrial trucks)

- 29 CFR 1910.307 [Hazardous (classified) locations]

3. National Emphasis Program (NEP)

OSHA’s Combustible Dust NEP details inspection procedures and targets industries at higher risk of explosions. This allows OSHA inspectors to identify combustible dust hazards, review safety programs, and examine housekeeping practices and ignition sources.

4. Key Safety Practices

To keep everyone safe from workplace fires, employers must:

- Identify and examine dust hazards

- Implement rigorous housekeeping for dust accumulation prevention

- Control all ignition sources, such as open flames, equipment heat, and static electricity

- Use proper dust collection systems

- Train employees to put out workplace fires

- Keep explosion protection and emergency action plans in place in case of disaster

5. NFPA Guidance

OSHA recommends these NFPA standards:

- NFPA 652: Fundamentals of Combustible Dust

- NFPA 654: Prevention of Fire and Dust Explosions

- NFPA 61, 484, 655, and more for specific industries

Combustible Dust Safety Standards: OSHA vs. NFPA

|

Category |

OSHA |

NFPA |

|

Regulatory Status |

Federal enforcement agency (mandatory compliance) |

Private organization (voluntary but widely adopted) |

|

Primary Focus |

Employee safety and health |

Fire and explosion prevention and control |

|

Legal Authority |

Enforced under the OSH Act, including the General Duty Clause |

Referenced in codes and can be adopted by AHJs (Authorities Having Jurisdiction) |

|

Key Regulations for Dust Hazards |

– 29 CFR 1910.22 (Housekeeping) – 29 CFR 1910.94 (Ventilation) – 29 CFR 1910.307 (Hazardous locations) – General Duty Clause (5(a)(1)) |

– NFPA 652 (Fundamentals of Combustible Dust) – NFPA 654 (Prevention of Fire and Dust Explosions) – NFPA 61, 484, 655, etc. for industry-specific guidance |

|

Enforcement Mechanism |

Inspections, citations, and fines |

Guidance for design and best practices; can be adopted into local codes |

|

Inspection Program |

NEP for combustible dust |

No inspections, but used by OSHA as a resource |

|

Training Requirements |

Employers must provide training on hazards (per General Industry Standards) |

NFPA recommends training but does not enforce |

|

Hazard Assessment Requirement |

Required under the General Duty Clause and NEP |

Required under NFPA 652 (Dust Hazard Analysis – DHA) |

|

Ignition Source Control |

Must address under 1910.307 and General Duty Clause |

Detailed control measures outlined (e.g., grounding, bonding, spark detection) |

|

Dust Collection Systems |

Should prevent dust accumulation and fire hazards |

Gives technical specifications for dust collection and suppression |

Historical Combustible Dust Incidents and Lessons Learned

Significant historical explosion incidents and the valuable lessons and insights gained from these tragedies. By examining notable past events with combustible dusts, and process equipment, we can better understand the importance of dust explosion prevention and safety measures in various industries.

Notable Explosions from the Past:

The Washburn “A” Mill Explosion (1878): Located in Minneapolis, Minnesota, this explosion was one of the deadliest in American history, resulting in the loss of 18 lives. The incident was a harsh reminder of the dangers of dust-related explosions in flour mills.

The Monongah Mining Disaster (1907): This coal dust explosion in Monongah, West Virginia, claimed the lives of 362 miners, making it one of the deadliest mining disasters in the United States. It highlighted the need for better dust control in mining operations.

The Benxihu Colliery Explosion (1942): Occurring in China’s Benxihu Colliery, this coal dust explosion was one of the world’s deadliest, leading to over 1,500 fatalities. The event underscored the global significance of controlling coal dust in mining.

The Imperial Sugar Refinery Explosion (2008): This explosion in Port Wentworth, Georgia, resulted from a sugar dust cloud ignition, leading to 14 fatalities and dozens of injuries. The incident emphasized the risks in the sugar industry and the need for strict dust management with combustible dust.

The West Fertilizer Company Explosion (2013): A fertilizer plant explosion in West, Texas, was fueled by ammonium nitrate dust. The disaster caused 15 deaths and raised concerns about handling dust in the chemical industry.

Lessons and Insights Gained from These Tragedies:

Combustible Dust Awareness: These historical incidents underscore the importance of recognizing the hazards associated with combustible dust, including a flash fire. Understanding that seemingly harmless dust, and even materials not commonly known to create dust, can catch fire and can become deadly and explosive, as awareness of combustible material is essential.

Regulations and Standards: In response to these tragedies, governments and industry organizations have developed regulations and safety standards to prevent explosions. For example, the U.S. Occupational Safety and Health Administration (OSHA) issued guidelines to help industries manage dust safely.

Proactive Prevention: Industries have learned to implement preventive measures, such as dust control, dust collectors, a dust collection system, and ventilation systems, to reduce the risk of dust cloud formation and ignition. Regular process equipment maintenance, inspections, and employee training are vital components of prevention.

Emergency Preparedness: Being prepared for a potential flash fire and explosion incidents is crucial. Companies have improved their emergency response plans, including evacuation procedures, communication, and first-aid training, to minimize the impact of secondary dust explosions.

Prevention and Mitigation Techniques for Dust Explosions

Steps and Best Practices to Prevent Combustible Dust Explosions:

Dust Hazard Analysis (DHA): Begin with a comprehensive DHA to identify potential explosion hazards in your facility. This involves evaluating the many materials and types of dust present, their quantities, and the processes that generate them.

Housekeeping: Maintain a rigorous housekeeping program to reduce the build up and accumulation of dusts. Regular cleaning and removal of dust accumulation from process equipment surfaces and the hidden surface area of a building, including suspended ceilings, or a confined space, can prevent the formation of dust clouds and an explosion hazard.

Isolation and Segregation: Isolate processes generate dust from areas where dust could potentially ignite. Segregation minimizes the risk of dust clouds encountering an ignition source.

Ventilation and Dust Collection Systems: Install effective ventilation systems, dust collectors, and a dust collection system to capture, prevent dust buildup, and remove dust at the source, or in a confined space. Ensure these systems are properly maintained and in good working condition.

Explosion Protection Measures: Implement explosion protection systems, such as explosion vents, suppression systems, and isolation devices, to mitigate the effects of a potential primary explosion and secondary explosion if it occurs.

Training and Education: Train employees on the hazards of dust and the proper handling and storage of materials that produce dust. Make sure they understand the emergency procedures.

Importance of Regular Facility Audits and Risk Assessments:

Regular facility audits and risk assessments are essential for maintaining a safe working environment. They provide several advantages:

Identification of Hazards: Audits and assessments help identify potential dust explosion hazards, ignition sources such as static electricity, including changes in processes, equipment, or materials that may have occurred since the last assessment.

Compliance with Regulations: Keeping up with regulatory compliance is vital. Regular audits ensure that the facility remains in adherence to evolving safety standards and guidelines.

Risk Reduction: Identifying and mitigating risks through assessments and audits reduces the likelihood of explosions and their associated dangers.

Dust Control and Management Strategies:

Material Selection: Whenever possible, use materials that generate less dust. Consider modifying processes or materials to reduce dust production.

Engineering Controls: Use engineering controls like enclosure and isolation to prevent dust dispersion. A Ventilation system and any dust collection system should be strategically placed to capture dust before it becomes a combustible dust hazard.

Maintenance: Regularly maintain and inspect equipment, any dust collection system, and safety systems to ensure they function as intended and prevent a combustible dust hazard.

Documentation: Keep detailed records of all dust-related activities, risk assessments, and safety measures to track and manage potential issues.

Ready to enhance your safety knowledge? Sign up now for expert guidance.

Tools and Technologies for Monitoring and Prevention of Dust Explosions

The prevention of explosions is a critical safety concern in various industries, and modern innovations have introduced a range of tools and technologies to address this issue.

Modern innovations have significantly enhanced the industry’s capacity to prevent dust accumulation on a surface area and explosions. Key tools and technologies include:

Explosion Risk Assessment Software: Advanced software tools enable companies to assess and quantify the risk of explosions within their facilities. These applications consider factors like dust particle size, concentration, and ignition sources, such as static electricity, allowing for the identification of high-risk areas.

Dust Sensors and Detectors: Specialized sensors and detectors have been developed to continuously monitor airborne dust levels and dust accumulation over a surface area or in a confined space. These real-time devices can trigger alarms or automatic shutdowns when dust concentrations reach dangerous levels, preventing the accumulation of hazardous materials.

Explosion Venting Systems: Explosion venting systems are designed to release the pressure generated during a dust explosion safely. These systems prevent the rupture of equipment, which can lead to secondary explosions. They divert the explosion energy away from critical areas, safeguarding personnel and equipment.

Inerting Systems: Inerting systems introduce inert gases, such as nitrogen, to reduce the oxygen content in enclosed spaces, making it difficult for explosions to occur. This is a proactive measure to prevent explosions from taking place in the first instance.

Flameless Venting Technology: Flameless venting systems are designed to capture and extinguish flames generated during an explosion. They help prevent secondary explosions and provide additional protection in case of a dust explosion.

Explosion Suppression Systems: These systems are designed to detect and suppress a dust explosion before it propagates. They use specialized extinguishing agents to quench the flame front rapidly, mitigating the effects of an explosion.

Dust Collection Systems: High-efficiency dust collection systems help in removing dust particles from the air, reducing the risk of dust accumulations that can lead to explosions.

Training and Education Programs: Equally important as technology is the training of personnel to recognize and address dust hazards. Proper training and education are key components of prevention.

Frequently Asked Questions (FAQ)

What is a combustible dust explosion?

A combustible dust explosion happens when fine particles suspended in the air suddenly ignite and burn rapidly or explode. This can occur when oxygen, dispersion of dust particles in the air, dust cloud confinement, fuel (combustible dust), and an ignition source, such as spark, heat, or flame, are present.

Which OSHA guidelines apply to preventing dust explosions?

OSHA may not have a dedicated standard for combustible dust, but these regulations and guidance documents help employers avoid dust explosions:

- General Duty Clause: Prompts employers to provide a safe work environment.

- 29 CFR 1910.22: Housekeeping to control the accumulation of dust.

- 29 CFR 1910.307: Controls for hazardous (classified) locations.

- 29 CFR 1910.94: Ventilation systems to reduce airborne dust.

- OSHA’s Combustible Dust NEP: Targets high-risk industries and provides inspection protocols.

- NFPA standards (recommended by OSHA), such as NFPA 652 and NFPA 654, detail the best practices for managing dust hazards.

Conclusion

Understanding and preventing explosions is paramount to ensuring workplace safety, protecting lives, and mitigating the devastating consequences that such incidents can bring.

Importance of Understanding and Preventing Explosions:

Preventing explosions is not merely a regulatory requirement; it is an ethical and practical imperative. The consequences of these incidents extend beyond financial losses and legal liabilities, encompassing the loss of human lives and environmental damage. A comprehensive understanding of combustible dust hazards and a commitment to prevention can lead to:

- Safety Enhancement: Protecting the lives of workers and the public by minimizing the risk of explosions.

- Legal Compliance: Avoiding penalties, fines, and legal consequences associated with non-compliance.

- Positive Reputation: Attracting customers and business partners by demonstrating a commitment to safety.

- Insurance Benefits: Reducing insurance costs and improving coverage options.

- Continuous Improvement: Fostering a culture of ongoing safety improvement and risk reduction within organizations.

Understanding and preventing explosions is an ongoing and crucial endeavor for industries worldwide. The importance of safety, compliance, and a proactive approach cannot be overstated, as these measures protect lives, assets, and the environment. By staying informed, adopting best practices, and fostering a culture of safety, organizations can effectively reduce the risk of explosions and contribute to safer workplaces globally.

Have a question? Contact us for tailored combustible dust safety solutions.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust Testing information, with a Podcast. Click on the latest Podcast Link: 10 Videos to Demonstrate and Educate About Dust Explosion Hazards

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.