Updated October 30, 2024 Authored by Dr. Chris Cloney and Jon Barrett

Key Takeaways:

- Awareness is Key: Recognize the hidden danger of combustible dusts in various industries and understand that raising awareness among your team is the first step in preventing potentially devastating combustible explosions.

- Proactive Risk Assessment: Conduct thorough risk assessments to identify areas with combustible dust hazards. This proactive approach helps you pinpoint vulnerabilities and implement targeted prevention measures.

- Compliance is Non-Negotiable: Stay up to date with industry regulations and standards. Compliance not only ensures safety but also safeguards your organization from legal consequences and fines.

- Prevention over Reaction: Prioritize prevention over reaction by investing in proper housekeeping practices, dust collection systems, and dust explosion protection measures. Prevention significantly reduces the likelihood of a dust explosion.

- Continuous Learning and Improvement: Embrace a culture of continuous improvement in combustible dust safety. Regular training, education, and ongoing review of safety practices are essential to stay ahead of evolving risks and protect your workforce effectively.

Table of Contents:

- What is Combustible Dust

- How Combustible Dust Explosions Occur

- Types of Combustible Dust

- Origins and Sources of Combustible Dust

- Industrial Processes that Generate Combustible Dust

- Everyday Activities Contributing to Combustible Dust Accumulation in Industrial Manufacturing Facilities

- Health Concerns Associated with Combustible Dust Inhalation

- Environmental Impact of Combustible Dust Pollution

- Awareness and Identifying Potential Hazards with Combustible Dust

- The Importance of Regular Cleaning of Combustible Dust

- Implementing a Comprehensive Combustible Dust Management Plan

- Conclusion

What is Combustible Dust?

Combustible dusts, also known as explosive dust, is a by-product created from manufacturing processes that involve combustible raw materials. Combustible dust refers to finely divided solid particles that are prone to ignition when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing. In this article, we will explain in more detail what qualifies dust as combustible and why it poses a significant risk, as a dust explosion hazard.

Dust qualifies as combustible when it possesses specific characteristics that make it prone to ignition and combustion when suspended in the air. These key attributes include particle size, concentration, and chemical composition. Fine particles, often smaller than 420 microns, are more likely to ignite due to their increased surface area. Additionally, a dust cloud must reach a certain concentration level in the atmosphere to become combustible. The chemical composition of the dust is another crucial factor, as certain materials have inherently flammable properties. Understanding these characteristics is vital for identifying and managing the risks associated with combustible dusts as a dust explosion hazard ensuring workplace safety and compliance. The National Fire Protection Association (NFPA) standards such as the NFPA 652, Standard on the Fundamentals of Combustible Dust, provides guidance on dust explosion prevention.

How Combustible Dust Explosions Happen

The scientific principles underlying how combustible dust explosions happen include the detailed breakdown of the combustion process, the factors that influence combustible dust hazards, dust explosions, and key concepts such as Minimum Ignition Energy (MIE), Minimum Explosible Concentration (MEC), and others.

Detailed Breakdown of the Combustion Process: Dust explosions follow a sequence of events that can be understood as a complex chemical reaction:

- Fuel: Fine particulate matter, such as dust or powdered materials, serves as the fuel. It can originate from various sources, including wood, metals, plastics, chemicals, and organic materials.

- Oxygen: The oxygen in the air acts as an oxidizer, required for combustion to occur.

- Ignition Source: An ignition source, which can be a spark, open flame, hot surface, friction, or electrical discharge, initiates the combustion process.

- Dust Suspension: Dust particles become suspended in the air, forming a dust cloud. The concentration of dust in the cloud must be within a specific range to support an explosion.

- Ignition: The dust cloud encounters an ignition source, causing the combustion of the suspended dust particles.

- Rapid Combustion: The combustion propagates throughout the dust cloud at an astonishingly high rate, generating pressure waves and fireballs, leading to an explosive release of energy.

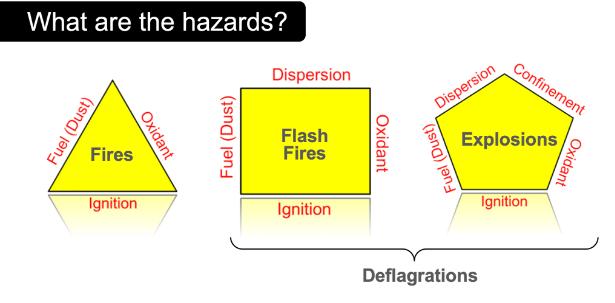

Factors Influencing a Dust Explosion (Fire Triangle for Dust):

The factors that influence dust explosions can be conceptualized using a “Fire Triangle” analogy, which includes three key elements:

- Fuel (Combustible Dust): The type and properties of the combustible dusts play a significant role in the likelihood of an explosion. Factors such as particle size, shape, chemical composition, and moisture content affect the explosiveness of the dust, and a dust explosion hazard.

- Oxygen (Air): The availability of oxygen in the air, often expressed as oxygen concentration, must be within a specific range to support combustion. Insufficient or excess oxygen can inhibit explosion propagation and a dust explosion hazard.

- Ignition Source: The presence of an ignition source is critical. Common sources include electrical equipment, welding operations, friction from moving machinery, and hot surfaces. Preventing or mitigating potential ignition sources is a key safety measure.

Key Terms and Concepts:

- Minimum Ignition Energy (MIE): MIE is the minimum amount of energy required to ignite a dust cloud when the air-fuel mixture is within its explosible range. It is typically measured in millijoules (mJ).

- Minimum Explosible Concentration (MEC): MEC is the lowest concentration of combustible dusts in the air that can support a dust explosion when an ignition source is present. Below this concentration, the mixture is too lean to explode; above it, the mixture is too rich.

- Dust Cloud Flammability Limits: These limits define the range of dust concentrations in which an explosion can occur. The lower explosive limit (LEL) and upper explosive limit (UEL) are specific concentrations below and above which explosions cannot occur.

- Dust Deflagration: A dust deflagration is a rapid combustion of dust that propagates at subsonic speed, generating pressure and fire but not a shockwave.

- Dust Detonation: A dust detonation is a supersonic combustion that produces shockwaves, leading to more destructive explosions. These are uncommon in most industrial processes, but may be possible in coal mining applications.

Understanding the science behind how combustible dust explosions happen, along with these key terms and concepts, is crucial for industries that handle combustible materials. It enables them to assess and mitigate the risks associated with dust, ensuring the safety of workers and preventing catastrophic incidents and any dust explosion hazard.

Types of Combustible Dusts

Organic Dust

Organic dust consists of finely divided particles originating from organic materials and solid material composed of grains, flour, sugar, wood, and certain agricultural products. Combustible dust vary in industries. These materials have the potential to produce fine powder and become combustible dusts when processed, handled, or transported. Organic dust poses a significant risk due to its ability to form explosive dust clouds when suspended in the air, making it crucial to implement preventive measures in industries like woodworking, food processing, and agriculture. The risk of combustion increases in environments where these particles can accumulate and form a cloud, creating a potential dust explosion hazard in industries like food processing, agriculture, and woodworking.

Metal Dust

Metal dust comprises tiny particles of solid material composed of metals like aluminum, titanium, zirconium, and magnesium. Metal dust, arising from processes like metal grinding, cutting, or polishing, poses a significant combustible dust hazard. These metals are known for their combustible nature, especially when reduced to fine dust. The fine nature of metal dust allows it to disperse easily, forming explosive mixtures in the air. The ignition of metal dust can result in intense fires and explosions, making proper containment and control imperative in industries like metalworking and aerospace manufacturing.

Plastic and Synthetic Dust

Plastic and synthetic dust originate from processes involving the handling, cutting, or grinding of solid material composed of plastics, rubber, or resins. These particles are lightweight and can form combustible mixtures in the air. Industries such as plastic manufacturing, recycling, and electronics must address the potential dangers associated with the accumulation of plastic and synthetic dust. Effective ventilation and housekeeping practices are crucial to reducing the risk of combustion and a dust explosion.

Other Types of Combustible Dusts

Combustible dusts can also arise from various other materials. Combustible dust vary in industries. Solid material may include dust from pharmaceuticals, textiles, paper, mining such as coal dust, and other diverse industries. The combustibility of these particles depends on factors such as size, concentration, and the presence of ignition sources. Recognizing the specific characteristics of different types of dust is essential for implementing tailored safety measures in a wide range of industrial settings. Regular risk assessments and preventive measures can help prevent combustible dust explosion and minimize the potential dust explosion hazards associated with these diverse dust types.

Origins and Sources of Combustible Dusts

Combustible dust is a devastating hazard that can arise from various industries and processes where fine particles become suspended in the air, forming explosive mixtures under the right conditions. Understanding the origins and sources of combustible dust is crucial for implementing effective safety measures. Here are some common origins and sources:

1. Woodworking:

Wood dust, generated during cutting, sanding, or processing wood materials, is highly combustible. Woodworking industries, including furniture manufacturing, mills, pallet manufacturing, and carpentry, are at risk of dust incidents due to the fine particles produced during these processes, including dust collectors. Woodworking shops in schools and universities provide valuable hands-on learning experiences but present potential hazards, including the risk of combustible dusts. Understanding the combustible particulate solid sources and risks associated with combustible dust and a dust explosion hazard in these educational settings is crucial for ensuring the safety of students and staff.

2. Food Processing:

Flour, sugar, corn, spices, and other organic materials used in food processing can create combustible dust. Bakeries, grain mills, and facilities handling powdered ingredients are susceptible to dust explosions. The fine particles from these combustible particulate solid materials can form explosive atmospheres in the presence of ignition sources.

3. Metalworking:

Metal dust, generated during operations like grinding, polishing, or welding, poses a significant combustible dust risk. Industries such as metal fabrication, machining, and foundries must address the potential for explosions caused by fine metal particles suspended in the air, from the combustible particulate solid material.

4. Chemical Manufacturing:

Certain chemicals, especially those in powder or granular form, can produce combustible dust. Industries involved in the manufacturing and processing of chemicals, pharmaceuticals, and plastics need to be vigilant about the potential dust explosion hazards associated with dust generated during production.

5. Agriculture:

Grain handling and storage facilities are prone to dust incidents. Dust from grains such as wheat, corn, and rice can accumulate and create explosive atmospheres. Agricultural processes, including drying and milling, contribute to the generation of combustible dust in these environments, from the combustible particulate solid material.

6. Textile Industry:

Cotton and other textile fibers can produce combustible dust during various manufacturing processes such as spinning and weaving. Textile facilities need to manage the risks associated with these fine particles to prevent dust explosions, from combustible particulate solid material.

Industrial Processes that Generate Combustible Dust

Industries across the spectrum face the looming threat of combustible dust, but certain sectors are particularly susceptible to this hazardous concern. Understanding the industries affected by combustible dust is vital for proactive risk management.

Among the list of industries most prone to combustible dust issues are woodworking and sawmills, where wood dust is prevalent, and food processing, where sugar and flour dust pose significant risks. Chemical manufacturing facilities handling materials like coal and sulfur are also at high risk for a flash fire. The metalworking industry, dealing with aluminum and magnesium, must remain vigilant. Agriculture and grain handling, pharmaceutical production, recycling facilities, and many others also contend with combustible dust challenges. By acknowledging the range of industries impacted, we emphasize the need for tailored safety measures, comprehensive training, and regulatory compliance to ensure the utmost protection for workers and assets in these high-risk environments, can prevent combustible dust explosion.

1. Woodworking and Paper Production

Woodworking and wood processing industries experience a notable number of combustible dust incidents. The fine dust produced during cutting, sanding, and shaping wood materials poses a serious hazard. Combustible dust in the paper industry primarily arises from the handling, processing, and refining of wood and other organic materials used in paper manufacturing. An example of a woodworking dust explosion occurred during the Bosley Mill Explosion.

2. Metalworking and Machining

Metal dust, generated during operations like grinding, polishing, or welding, poses a significant combustible dust risk. Industries such as metal fabrication, machining, and foundries must address the potential for a possible flash fire and explosions caused by fine metal particles suspended in the air.

3. Chemical Manufacturing

Certain chemicals, especially those in powder or granular form, can produce combustible dust. Industries involved in the manufacturing and processing of chemicals, pharmaceuticals, and plastics need to be vigilant about the potential flash fire hazards associated with dust generated during production, and dust suspended in air.

4. Food and Grain Processing

Flour, sugar, corn, spices, and other organic materials used in food processing can create combustible dust. Bakeries, grain mills, and facilities handling powdered ingredients are susceptible to dust explosions. The fine particles from these materials can form a combustible dust hazard, as explosive atmospheres in the presence of ignition sources when suspended in air.

Everyday Activities Contributing to Combustible Dust Accumulation in Industrial Manufacturing Facilities

Industrial manufacturing facilities face a constant challenge in managing combustible dust, which can lead to hazardous conditions if not properly addressed. Everyday activities within these facilities can inadvertently contribute to the accumulation of combustible dust and dust suspended in air and a flash fire hazard. Identifying and understanding these activities is crucial for implementing effective preventive measures. Here are some common contributors:

1. Material Handling and Transfer:

The handling and transfer of raw materials, especially powders and granular substances, can generate dust. Activities such as loading and unloading, conveyor belt operations, and material transfer between containers or processes can disperse fine particles into the air, contributing to particulate accumulation.

2. Machining and Grinding Operations:

Processes like machining, grinding, and sanding generate significant amounts of fine particulate matter. Metalworking operations, for instance, produce metal dust that is highly combustible. The continuous use of equipment without proper dust containment can result in the gradual buildup of combustible dust in workspaces and may cause a flash fire hazard.

3. Cleaning and Maintenance:

While cleaning and maintenance activities are essential for equipment efficiency, they can inadvertently contribute to dust dispersal. Sweeping, compressed air cleaning, and maintenance practices that involve dislodging settled dust can reintroduce fine particles into the air, leading to particulate accumulation and may cause a flash fire hazard.

4. Conveyor Systems:

Conveyor systems play a crucial role in material transport within manufacturing facilities. However, the friction and movement of materials on conveyor belts can generate dust. Over time, this dust can accumulate on and around the conveyor systems, posing a potential combustion risk.

5. Packaging and Filling Operations:

Packaging and filling operations, especially those involving powders and granules, can release fine particles into the air. The filling of bags, containers, or other packaging materials may generate dust that settles on surfaces and contributes to the overall dust load within the facility.

6. Equipment Leakages:

Leakages from equipment such as dust collectors, hoppers, pipes, or ducts can release powders or particulate matter into the surrounding environment. This can occur due to mechanical wear, poor seals, or other equipment malfunctions, leading to the unintended dispersion of combustible dust, and creating possible dust clouds and flash fire.

7. Bulk Material Storage:

Storage of bulk materials in bins or silos can result in dust settling over time. When these materials are subsequently handled or transferred, the disturbance can re-suspend the settled dust, increasing the risk of combustion, possible dust clouds, and flash fire.

Health Concerns Associated with Combustible Dust Inhalation

In industrial settings where combustible dust is present, inhalation of airborne particles can pose serious health risks to workers. The fine nature of combustible dust particles makes them easily respirable, when suspended in air, allowing them to penetrate deep into the respiratory system. Here are some health concerns associated with combustible dust inhalation:

1. Respiratory Irritation:

Inhalation of combustible dust suspended in air can irritate the respiratory system, leading to symptoms such as coughing, wheezing, and shortness of breath. Prolonged exposure may contribute to the development or exacerbation of respiratory conditions like asthma and bronchitis.

2. Chronic Respiratory Diseases:

Long-term exposure to combustible dust may contribute to the development of chronic respiratory diseases. Workers in industries with high dust concentrations, such as woodworking, metalworking, or food processing, may be at an increased risk of conditions like chronic obstructive pulmonary disease (COPD) over time.

3. Allergic Reactions:

Certain combustible dust particles, especially those derived from organic materials, can act as allergens. Individuals may experience allergic reactions upon inhalation, including nasal congestion, sneezing, and itchy or watery eyes. Sensitized individuals may develop allergic respiratory conditions.

4. Respiratory Tract Infections:

The presence of combustible dust in the respiratory system can compromise the body’s natural defense mechanisms, making individuals more susceptible to respiratory tract infections. Dust-laden airways provide an environment conducive to the growth of bacteria and viruses, increasing the risk of infections.

5. Occupational Lung Diseases:

Workers exposed to high concentrations of combustible dust over extended periods may be at risk of developing occupational lung diseases. These conditions can include pneumoconiosis, a group of lung diseases caused by the inhalation of dust particles, leading to inflammation and scarring of the lung tissue.

6. Cardiovascular Effects:

Studies suggest that prolonged exposure to airborne particulate matter, including combustible dust, may have cardiovascular effects. Inhaling fine particles can trigger systemic inflammation, potentially contributing to cardiovascular diseases in the long term.

7. Cancer Risk:

Certain types of combustible dust, particularly those containing carcinogenic substances, may pose a cancer risk upon inhalation. Workers in industries such as metalworking or chemical processing, where carcinogenic materials are present, should be particularly cautious about dust exposure.

Environmental Impact of Combustible Dust Pollution

Combustible dust pollution not only poses significant risks to human health and safety but also has adverse effects on the environment. The release of fine particles into the air, water, and soil during combustible dust incidents can lead to a range of environmental challenges.

1. Air Quality Degradation:

Combustible dust events, particularly those resulting in explosions or fires, release large quantities of particulate matter into the air. These fine particles, when airborne and suspended in air can contribute to poor air quality in the surrounding environment. Prolonged exposure to elevated levels of particulate matter may have detrimental effects on respiratory health in humans and other living organisms.

2. Soil Contamination:

Dust fallout from combustible dust incidents can settle on the ground, leading to soil contamination. The composition of the dust, which may include metals, chemicals, or other pollutants, can adversely affect soil quality. Contaminated soil may impact plant growth and disrupt the balance of ecosystems.

3. Water Pollution:

Combustible dust, when carried by wind or runoff, can find its way into water bodies, leading to water pollution. The introduction of dust particles, along with any associated contaminants, may have adverse effects on aquatic ecosystems. It can disrupt aquatic life, affect water quality, and accumulate in sediments.

4. Impact on Flora and Fauna:

The fallout of combustible dust can directly impact plants and animals in the affected area. Dust settling on vegetation may interfere with photosynthesis and nutrient absorption, affecting plant health. In aquatic ecosystems, fish and other aquatic organisms may be exposed to contaminants, disrupting their habitats and life cycles.

5. Environmental Impact of Combustible Dust Pollution on Pollinators:

Combustible dust pollution, stemming from industrial activities, can have far-reaching consequences on the environment, with potential impacts on essential ecological components such as pollinators. Pollinators, including bees, butterflies, and other insects, play a crucial role in maintaining biodiversity and supporting ecosystems. Here’s an exploration of how combustible dust pollution can affect these vital contributors to our environment:

- Disruption of Pollinator Habitats: Combustible dust incidents can lead to the release of fine particles into the air, settling on vegetation and soil. Pollinator habitats, including flowering plants, may be directly impacted, affecting their accessibility and the availability of nectar and pollen for bees and other pollinators. The disruption of these habitats can lead to decreased foraging success and overall pollinator health.

- Contamination of Nectar and Pollen: Dust fallout onto plants can contaminate nectar and pollen, potentially exposing pollinators to harmful substances. Pollinators, such as bees, rely on the nectar and pollen they collect for their nutrition. Contaminated food sources may have detrimental effects on their health, affecting their ability to reproduce and fulfill their role in pollination.

- Respiratory Stress on Pollinators: Airborne combustible dust particles can pose a respiratory threat to pollinators, particularly those with delicate respiratory systems like bees. Inhaling dust particles may lead to respiratory stress, impacting their ability to navigate and forage effectively.

- Impact on Reproductive Success of Pollinators: Pollinators are crucial for the reproduction of many flowering plants. Combustible dust pollution can interfere with the reproductive success of both plants and pollinators. Contaminated pollen may affect the fertility of plants, while the health of pollinators can be compromised, potentially leading to population declines.

6. Long-Term Ecological Effects:

Chronic exposure to combustible dust pollution can have long-term ecological consequences. Persistent contamination of air, soil, and water may lead to cumulative impacts on biodiversity, potentially causing changes in species composition and ecosystem dynamics.

7. Contribution to Global Environmental Issues:

Certain combustible dust particles, especially those derived from industrial processes, may contain pollutants that contribute to global environmental issues. For example, the release of heavy metals or toxic chemicals during dust incidents may contribute to environmental problems such as acid rain or the degradation of ozone in the atmosphere.

Awareness and Identifying Potential Hazards with Combustible Dust

Awareness starts with recognizing the existence of combustible dust in the workplace. Many employees and management might not be fully aware of the risks associated with combustible dust particles. Through education and training, individuals can learn to identify potential sources of combustible dust and be vigilant in their presence. Industrial facilities can promote awareness regarding how combustible dust explosions happen, in several ways:

- Training Programs: Implement comprehensive training programs that educate employees at all levels about the risks associated with combustible dust. These programs should cover identification, prevention, and response strategies.

- Regular Communication: Maintain open lines of communication between employees, management, and safety officers. Regularly discuss safety measures and encourage employees to report any concerning conditions.

- Safety Campaigns: Launch safety campaigns that emphasize the importance of awareness in preventing dust explosions. Use posters, pamphlets, and workshops to engage and inform employees.

- Continuous Learning: Awareness should be an ongoing process. Stay updated on the latest safety practices and technological advancements in dust explosion prevention and protection.

- Management Support: Ensure that the organization’s leadership is fully supportive of awareness initiatives. Management’s commitment to safety sends a powerful message to the entire workforce.

- Reward System: Implementing a reward system, for prevention of Combustible Dust explosions, can be an effective and innovative approach.

The reward system focuses on incentivizing and promoting best practices in dust explosion prevention. It encourages employees at all levels, from floor workers to management, to actively participate in maintaining a safe environment. By rewarding individuals and teams who contribute to dust explosion prevention efforts, the system not only recognizes their dedication but also fosters a culture of safety within the organization.

The key components of this reward system include the identification of dust hazards, regular maintenance and cleaning, adherence to safety protocols, and active reporting of potential hazards. By tying these activities to tangible rewards, organizations can motivate their workforce to remain vigilant and proactive in preventing dust explosions.

The implementation of a reward system for preventing combustible dust explosions is a proactive and engaging strategy for industrial manufacturing facilities. It not only enhances safety measures but also instills a culture of prevention, ultimately reducing the risk of catastrophic dust explosions and safeguarding employees and assets.

The Importance of Regular Cleaning of Combustible Dust

Regular cleaning serves as the first line of defense against dust hazards. When dust particles are allowed to accumulate over time, they create an environment ripe for potential explosions. These tiny particles, often unseen to the naked eye, can become suspended in the air, waiting for the right conditions to ignite and trigger a devastating explosion. By keeping work areas clean, the amount of dust available for resuspension, dispersion, and combustion is significantly reduced.

Best Practices for Housekeeping

Effective housekeeping practices involve a combination of strategies and best practices:

- Scheduled Cleaning: Establish a routine cleaning schedule to ensure that work areas, equipment, and surfaces are cleaned regularly. The frequency of cleaning should be tailored to the specific conditions of each workspace.

- Proper Tools and Equipment: Use appropriate cleaning tools and equipment, such as industrial vacuums, dust collectors, and cleaning solutions, to effectively capture and remove dust without dispersing it into the air.

- Comprehensive Dust Removal: Ensure that all areas, including overhead structures, crevices, and hidden corners, are thoroughly cleaned to prevent dust accumulation.

- Safety Training: Train employees on safe cleaning procedures, emphasizing the importance of following safety guidelines to minimize the risk of ignition during the cleaning process.

- Controlled Disposal: Establish protocols for the safe disposal of collected dust to prevent its reintroduction into the environment. Dust collected should be safely stored in designated containers.

The Role of Management and Employees with Housekeeping

Effective housekeeping practices require a commitment from both management and employees. Management should lead by example, providing the necessary resources, training, and support for the implementation of these practices. Employees, on the other hand, must actively participate in maintaining a clean and safe workspace. Reporting any concerns or deviations from established cleaning schedules is vital for ensuring that housekeeping practices remain effective.

Housekeeping practices that involve regular cleaning to minimize combustible dust accumulation are a fundamental and effective prevention measure in the fight against combustible dust explosions. By creating a culture of cleanliness and safety in the workplace, organizations can significantly reduce the risks associated with dust explosions, protecting both their employees and valuable assets.

Implementing a Comprehensive Combustible Dust Management Plan

Combustible dust poses a significant risk in various industries, including manufacturing, food processing, and woodworking. The accumulation of fine particles in the air can lead to explosions, fires, and other hazardous incidents. To mitigate these risks, implementing a comprehensive combustible dust management plan is crucial. This plan should encompass identification, assessment, prevention, and response strategies to ensure a safe working environment.

Identification of Combustible Dust Hazards:

- Material Assessment: Begin by identifying materials that could generate combustible dust. Common examples include wood, metal, plastic, and certain chemicals. Evaluate their properties to determine their combustibility.

- Process Analysis: Assess the processes within the facility that could create or disperse combustible dust. This includes grinding, sanding, cutting, and other activities that produce fine particles.

- Equipment Inspection: Regularly inspect machinery and equipment for dust accumulation. Identify areas where dust is likely to collect and take preventive measures.

Risk Assessment:

- Hazardous Zones Mapping: Define hazardous zones where combustible dust concentrations are most likely. This mapping helps in focusing preventive measures and controls in high-risk areas.

- Risk Matrix Development: Develop a risk matrix to prioritize areas and processes based on the severity of the potential hazard and the likelihood of an incident occurring.

Preventive Measures:

- Housekeeping Procedures: Establish strict housekeeping procedures to minimize dust accumulation. Regular cleaning of work areas, surfaces, and equipment is essential.

- Ventilation Systems: Implement effective ventilation systems to capture and remove airborne dust. Ensure that these systems are properly maintained and regularly inspected.

- Equipment Design: Select and use equipment with designs that minimize dust generation. Enclose processes where possible to contain dust and prevent its dispersion.

Training and Awareness:

Provide comprehensive training to employees on dust hazards, prevention methods, and emergency response procedures. Foster a culture of awareness and responsibility.

Response and Emergency Preparedness:

- Emergency Response Plan: Develop a detailed emergency response plan that outlines procedures to follow in the event of a combustible dust incident. Conduct regular drills to ensure readiness.

- Fire Suppression Systems: Install appropriate fire suppression systems, such as sprinklers and extinguishers, in areas prone to combustible dust. Ensure these systems are regularly tested and maintained.

- Communication Protocols: Establish clear communication protocols for alerting personnel about potential dust hazards and emergency situations. This includes alarms, notifications, and evacuation procedures.

Continuous Improvement and Compliance:

- Regular Audits and Inspections: Conduct regular audits and inspections to assess the effectiveness of the combustible dust management plan. Identify areas for improvement and address them promptly.

- Regulatory Compliance: Stay informed about relevant regulations and standards related to combustible dust management. Ensure that the plan remains in compliance with industry-specific guidelines. The National Fire Protection Association (NFPA) standards such as the NFPA 652, Standard on the Fundamentals of Combustible Dust, provides guidance on dust explosion prevention.

- Incident Investigation: In the event of an incident, conduct thorough investigations to identify the root causes and implement corrective actions to prevent recurrence.

Conclusion

Understanding and preventing dust explosions is paramount to ensuring workplace safety, protecting lives, and mitigating the devastating consequences that such incidents can bring.

Importance of Preventing and Protection from Combustible Dust Explosions:

Preventing dust explosions is not merely a regulatory requirement; it is an ethical and practical imperative. The consequences of these incidents extend beyond financial losses and legal liabilities, encompassing the loss of human lives and environmental damage. A comprehensive understanding of dust hazards and the commitment to prevention can lead to:

Safety Enhancement: Protecting the lives of workers and the public by minimizing the risk of explosions.

Legal Compliance: Avoiding penalties, fines, and legal consequences associated with non-compliance.

Positive Reputation: Attracting customers and business partners by demonstrating a commitment to safety.

Insurance Benefits: Reducing insurance costs and improving coverage options.

Continuous Improvement: Fostering a culture of ongoing safety improvement and risk reduction within organizations.

Recommendations for Further Reading and Resources:

- NFPA Standards: Explore the National Fire Protection Association’s guidelines and standards related to combustible dusts (NFPA 652, NFPA 654, etc.).

- OSHA Resources: The U.S. Occupational Safety and Health Administration (OSHA) offers valuable resources on combustible dust safety.

- European ATEX Directive: Study the ATEX directive for European Union member states, which focuses on equipment used in potentially explosive atmospheres.

- Industry Publications: Many industry-specific publications and journals provide in-depth information on dust hazards and prevention measures.

- Safety Training Programs: Consider enrolling in safety training programs that cover combustible dust safety and risk assessment.

- Government Guidelines: Review the guidelines and resources provided by relevant government agencies in your region, such as the Health and Safety Executive (HSE) in the UK.

- International Safety Organizations: Explore international safety organizations and their publications, like the Institution of Chemical Engineers (IChemE).

Understanding and preventing combustible dust explosions is an ongoing and crucial endeavor for industries worldwide. The importance of safety, compliance, and a proactive approach cannot be overstated, as these measures protect lives, assets, and the environment. By staying informed, adopting best practices, and fostering a culture of safety, organizations can effectively reduce the risk of combustible dust explosions and contribute to safer workplaces globally.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust information, with a Podcast. Click on the latest Podcast Link: 10 Videos to Demonstrate and Educate About Dust Explosion Hazards

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.