Updated February 11, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Key Takeaways:

- Understanding Combustible Dust Hazards: Combustible dust is a serious workplace hazard that can lead to catastrophic fires and combustible dust explosions.

- The Importance of Mitigation and Prevention: Prevention is the most effective approach to mitigating combustible dust-related incidents, and dust explosions.

- Compliance with Regulations and Standards: Governments and safety organizations have established regulations and standards to address combustible dust risks and dust explosions.

Table of Contents:

- Why is Combustible Dust Flammable?

- Which Products and Materials May Cause a Combustible Dust Explosion?

- Is Household Dust Flammable?

- Is Flammable Dust Always a Problem?

- Is All Dust Flammable?

- Can Dust Particles Ignite?

- Can Static Electricity Ignite Dust?

- Does Fire Burn Dust?

- What Kind of Dust is Flammable?

- Can Dust Spark a Fire?

- Conclusion

- Recommendations for Further Reading and Resources

Why is Combustible Dust Flammable?

Is dust flammable? Yes, dust is flammable due to a combination of factors that make it particularly susceptible to ignition. When dust particles are finely divided, they can disperse in the air and create a mixture with oxygen, which is essential for combustion. Additionally, certain types of dust, such as organic or metallic dust, can have low ignition temperatures, making them more prone to catching fire and causing a dust explosion. These factors, coupled with the potential for electrostatic discharge or other ignition sources, underscore the importance of understanding dust flammability and implementing safety measures to mitigate the risks associated with combustible dusts in various industries.

Which Products and Materials May Cause Combustible Dust Explosions?

Combustible Dust and organic dust particulates are derived from natural materials such as wood, grains, sugar, powdered milk, and flour. These materials have the potential to produce fine, dust when processed, handled, or transported. The finely divided solid particles and dust poses a significant risk due to its ability to form explosive dust clouds when suspended in the air. As a result, it is crucial to implement preventive measures in industries like woodworking, food processing, and agriculture, where combustible dust explosions happen. Combustible dust vary in explosion characteristics. When a primary dust explosion occurs, a secondary explosion may also occur, from fugitive dust. The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations.” These technical definitions are important for employee training and awareness.

Materials Vary in Explosion Characteristics

Metal dust comprises tiny particles of metals like aluminum, zirconium, and magnesium. These metals are known for their combustible nature, especially when reduced to fine dust. The ignition of dust can result in intense fires and a dust explosion, making proper containment and control imperative in industries like metalworking and aerospace manufacturing.

Chemical dust includes substances like coal and sulfur, which can be highly flammable when in particulate form. These materials often pose additional challenges due to their chemical reactivity and the potential for toxic byproducts during combustion. Managing chemical dust hazards is crucial in industries such as plastics manufacturing, mining, and energy production, to prevent a dust explosion.

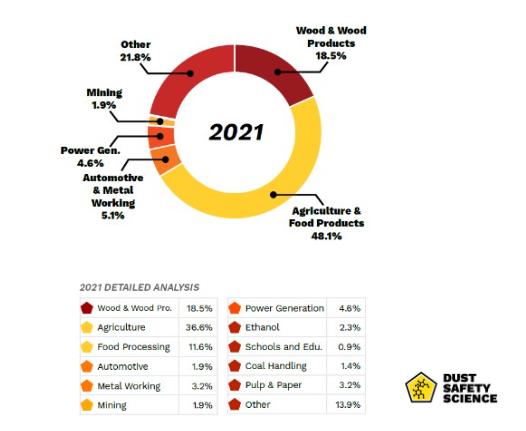

Industries Prone to Flammable and Combustible Materials

Among the list of industries most prone to combustible dust issues are woodworking and sawmills, where dust is prevalent, and food processing, where sugar and flour dust pose significant risks. Chemical manufacturing facilities handling materials like coal and sulfur are also at high risk. The metalworking industry, dealing with aluminum and magnesium, must remain vigilant. Agriculture and grain handling, pharmaceutical production, recycling facilities, and many others generate combustible dust and also contend with combustible dusts challenges. By acknowledging the range of industries impacted, we emphasize the need for tailored safety procedures, comprehensive training, and regulatory compliance to ensure the utmost protection for workers and assets in these high-risk environments, and to prevent primary and secondary dust explosions.

Is Household Dust Flammable?

Household dust is composed of a variety of tiny particles, including skin cells, pet dander, pollen, and minute debris from daily activities. While household dust itself is not typically flammable, it can become a fire hazard under certain conditions. When disturbed, fine particles of dust can become suspended in the air, forming a cloud. If this cloud encounters an ignition source, such as an electrical spark, or static, it can lead to a flash fire. To mitigate the risk, regular cleaning and dust control measures are essential to prevent dust buildup and the formation of flammable clouds in the home. Understanding this potential hazard highlights the importance of maintaining a clean and safe living environment. Example materials that have resulted in combustible dust fires, flash-fires, and dust explosions, in non-commercial environments include fine flour products, icing sugar, fine sawdust, cornstarch, and baby powder.

Is Flammable Dust Always a Problem?

Flammable dust, while inherently a hazard, is not always a problem when proper precautions and safety procedures are in place. The level of risk associated with dust depends on various factors, including the type of dust, its concentration, and the presence of ignition sources. Industries that handle combustible materials must implement strict safety protocols, including dust control, equipment grounding, and hazard awareness training, to minimize the risk of dust-related fires and explosions. When managed effectively, combustible dusts can be safely handled and controlled, emphasizing the importance of proactive measures to prevent potential problems.

Is All Dust Flammable?

Not all dust is inherently flammable. The flammability of dust depends on several factors, including the type of material it consists of and its particle size. While some dust, like flour, wood, rubber, coal dust, metals and plastics can be highly flammable when finely dispersed in the air, others, such as dirt or dust made up of non-combustible materials, are not flammable. It’s essential to recognize that the flammability of dust is specific to the material and conditions, and not all dust poses a fire or explosion risk. However, it is crucial to assess and manage the potential hazards associated with combustible dusts to ensure workplace and environmental safety, to prevent dust explosions.

Can Dust Particles Ignite?

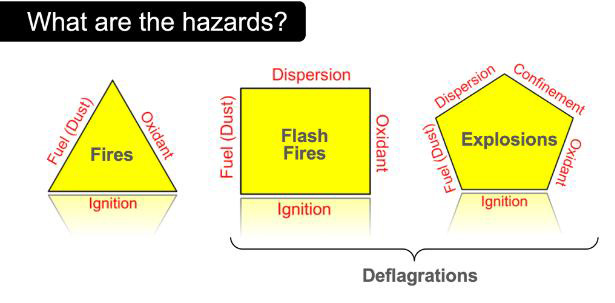

Dusts can indeed ignite under certain conditions. While individual dust particulates are not typically flammable, they become a potential hazard when they form a cloud in the air. When this cloud encounters an ignition source, such as a spark or open flame, it can lead to a fire or explosion. This phenomenon is especially relevant in industries that handle materials, like grain processing or woodworking, where fine dust can accumulate in a confined space, and pose a significant risk. This explosion process refers to the dust explosion pentagon. Therefore, understanding the potential for dust particulates to ignite highlights the importance of proactive safety procedures, including dust control, dust accumulation, and hazard mitigation, to prevent accidents and maintain a safe environment.

Can Static Electricity Ignite Dust?

Static can indeed ignite dust, particularly in environments where fine dust are present. When materials move or rub against each other or surfaces, they can generate static. This static charge can accumulate on the surface of dust particles, creating conditions conducive to ignition. If a cloud is formed and comes into contact with an electrostatic discharge, such as a spark from static, it can result in ignition, potentially leading to a fire or explosion. This risk is particularly relevant in industries handling bulk materials, highlighting the importance of effective static control measures and safety protocols to prevent such incidents. See our article on combustible dust testing for more information on evaluating static and its ability to ignite combustible dust.

Does Fire Burn Dust?

Fire can indeed burn dust, but the combustion of dust depends on various factors, including the type of dust, its concentration, and the presence of an ignition source. Dust itself is not typically flammable in its bulk solid form. However, when dust is finely dispersed in the air, it can become highly flammable. In this state, if a fire or ignition source is introduced, the dust can ignite and burn rapidly, potentially causing a dust explosion. This phenomenon is a significant concern in industries handling bulk materials, highlighting the importance of dust control and fire prevention measures to mitigate the risk and ensure workplace safety.

What Kind of Dust is Flammable?

The flammability of dust is specific to the type of material it consists of. Generally, dust derived from bulk materials like wood, metal, coal, grain, chemicals, and some organic substances can be highly flammable. When this fine dust is dispersed, and suspended in air, it forms a potentially explosive cloud. However, not all dust is flammable. Dust composed of non-combustible materials like dirt or sand does not pose the same fire or explosion risk. Identifying the type of dust in an environment is crucial for assessing and managing the potential hazards, emphasizing the importance of proactive National Fire Protection Association, NFPA, and OSHA safety procedures in industries where combustible dust is present.

Overview of Industries with Heightened Risks of Combustible Dust:

Agriculture and Food Processing: Industries dealing with grains, cereals, powdered milk, and agricultural products are particularly susceptible to explosions. Silos, milling facilities, and food processing plants often create conditions conducive to dust explosions.

Woodworking and Sawmills: Wood dust, generated from cutting, sanding, and processing wood, including the dust collectors and dust collection systems, can lead to hazardous wood dust clouds. Woodworking shops, lumber mills, and furniture manufacturing are at risk of secondary dust explosions.

Metalworking: Dust, generated during grinding, cutting, and polishing, can ignite, catch fire, and explode. Metalworking facilities, including foundries and machining shops, must manage the risk of explosions.

Chemical and Pharmaceutical Manufacturing: Chemicals and pharmaceuticals can produce combustible dust, and dust hazards, especially when they are in powdered form, and cause a flash fire. Ensuring safe handling and storage is vital.

Plastics and Rubber Industries: These industries produce fine dust during processing and molding. Dust explosions can occur in plastic and rubber manufacturing facilities, making dust control crucial.

Textile Mills: The textile industry generates significant dust from fibers and dyes, and build up in dust collectors and dust collection systems. Cotton, wool, and synthetic materials can all catch fire, and contribute to combustible dust risks.

Energy and Utilities: Power plants, particularly coal-fired or biomass-burning ones, can experience coal dust explosions. Dust generated from the handling and transportation of coal or biomass can catch fire, and poses significant risks.

Case Studies from Different Industries:

Grain Elevators: The 1977 explosion at the DeBruce Grain Elevator in Kansas, USA, claimed seven lives. A cloud ignited, causing a catastrophic dust explosion blast that led to industry-wide safety improvements.

Chemical Manufacturing: The 2008 explosion at the T2 Laboratories chemical plant in Florida resulted from the mishandling of hazardous chemicals in powdered form. The explosion tragically led to fatalities and the destruction of the facility.

Sugar Refineries: In 2008, the Imperial Sugar Refinery in Georgia, USA, suffered a massive dust explosion, killing 14 people and injuring dozens. The incident underscored the importance of proper dust control in the sugar industry.

Woodworking: The Wood Flour Mills explosion in the UK in 2015 highlighted the risks in woodworking. Five people lost their lives, and the event emphasized the need for improved dust management practices.

Metalworking: A dust explosion occurred at a metal powder manufacturing facility in Germany in 2019. Though there were no casualties, the event led to industry-wide awareness about dust hazards.

Can Dust Spark a Fire?

Dust can indeed spark a fire, especially in environments where fine particles of dust are present in sufficient concentration and with layers of dust accumulation, in a confined space. When dust particles become airborne, they can form a potentially dust clouds. In the presence of an ignition source, such as an electrical spark, open flame, or hot surface from dust collection systems, or ventilation systems, the cloud can ignite and lead to a fire or a dust explosion. This phenomenon is a significant concern in industries dealing with bulk materials. This hazard underlines the importance of proper dust control, safety procedures, and hazard awareness to prevent dust related fires, prevent combustible dust explosion, and maintain a safe working environment.

Conclusion

Understanding and preventing explosions is paramount to ensuring workplace safety, protecting lives, and mitigating the devastating consequences and that dust explosions happen.

Importance of Understanding and Preventing Combustible Dust Explosions:

Preventing an explosion hazard and explosions, are not merely a regulatory requirement; it is an ethical and practical imperative. As OSHA defines combustible dust, education, prevention, and awareness are keys to keeping a workplace safe, with employee training. The consequences of these incidents extend beyond financial losses and legal liabilities, encompassing the loss of human lives and environmental damage. A comprehensive understanding of a combustible dust hazard and the commitment to prevention can lead to:

Safety Enhancement: Protecting the lives of workers and the public by minimizing the risk of explosions.

Legal Compliance: Avoiding penalties, fines, and legal consequences associated with non-compliance.

Positive Reputation: Attracting customers and business partners by demonstrating a commitment to safety.

Insurance Benefits: Reducing insurance costs and improving coverage options.

Continuous Improvement: Fostering a culture of ongoing safety improvement and risk reduction within organizations.

Recommendations for Further Reading and Resources:

- NFPA Standards: Explore the National Fire Protection Association’s guidelines and standards related to combustible dust (NFPA 652, NFPA 654, etc.).

- OSHA Resources: The U.S. Occupational Safety and Health Administration (OSHA) offers valuable resources on combustible dust safety.

- European ATEX Directive: Study the ATEX directive for European Union member states, which focuses on equipment used in potentially explosive atmospheres.

- Industry Publications: Many industry-specific publications and journals provide in-depth information on combustible dust hazards and prevention measures.

- Safety Training Programs: Consider enrolling in safety training programs that cover combustible dust safety and risk assessment.

- Government Guidelines: Review the guidelines and resources provided by relevant government agencies in your region, such as the Health and Safety Executive (HSE) in the UK.

- International Safety Organizations: Explore international safety organizations and their publications, like the Institution of Chemical Engineers (IChemE).

Understanding and preventing dust explosions is an ongoing and crucial endeavor for industries worldwide. The importance of safety, compliance, and a proactive approach cannot be overstated, as these measures protect lives, assets, and the environment. By staying informed, adopting best practices, and fostering a culture of safety during employe training, organizations can effectively reduce the risk of an explosion hazard and contribute to safer workplaces globally.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust information, with a Podcast. Click on the latest Podcast Link: 10 Videos to Demonstrate and Educate About Dust Explosion Hazards

Resources:

Visit: Dust Safety Science’s Training Page

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.