Updated March 21, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Every example of combustible dust serves as a reminder of its hidden hazards—learn how to mitigate the risks and enhance workplace safety.

Combustible dust is a hidden danger lurking in various industries, often underestimated or overlooked until it’s too late. Understanding combustible dust hazards is critical, as neglecting these hazards can lead to devastating explosions, fires, and severe workplace injuries.

This comprehensive guide explains combustible dust, provides real-world examples of combustible dust incidents, and, most importantly, outlines effective dust management strategies to ensure occupational safety in the workplace.

A flash fire hazard and dust explosions caused by combustible dust can lead to devastating consequences, including loss of life, injuries, property damage, and environmental harm.

Key Takeaways:

- Learn About Combustible Dust Examples: Learn about combustible dust examples and solutions to enhance workplace safety and prevent hazardous combustible dust explosions and incidents.

- Combustible Dust Management Techniques: Explore a variety of strategies and methods for the collection and cleaning of combustible dust, safeguarding your facility from potential ignition sources and possible combustible dust explosions.

- Compliance and Best Practices: Stay up-to-date with industry compliance requirements and discover best practices to maintain a combustible dust-free environment, promoting occupational safety, ensuring a secure and efficient workspace, and preventing a flash fire hazard and possible combustible dust explosions.

Protect your workplace from the risks of combustible dust.

INDEX

- What is Combustible Dust?

- Common Examples of Combustible Dust and Industry Incidents with Explosions

- The Science of Combustible Dust

- Dangers of Combustible Dust

- How to Manage Combustible Dust Safely

- Conclusion

What is Combustible Dust?

Combustible dust refers to finely divided solid particles that are prone to ignition when suspended in the air. Combustible dust particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing. In this section, we’ll delve deeper into what qualifies dust as combustible and why it poses a significant risk for combustible dust hazards and a potential combustible dust explosion.

Key Characteristics of Combustible Dust:

- Particle Size: Fine particles (typically smaller than 420 microns) have a larger surface area, increasing their combustibility.

- Concentration in Air: A dust cloud must reach a specific concentration level to become explosive.

- Chemical Composition: Some materials, such as organic substances and fine metals, are inherently more flammable.

Definition by OSHA: Combustible dust is “a solid material composed of distinct particles or pieces, regardless of size, shape, or composition, which presents a fire or deflagration hazard when suspended in air.”

Understanding these characteristics is crucial for identifying hazards, ensuring compliance, and preventing a combustible dust explosion.

Don’t let combustible dust risks catch you off guard.

Common Examples of Combustible Dust and Industry Incidents with Explosions

Combustible dust can originate from a variety of solid materials, including wood, grains, sugar, flour, metals, dyes, plastic powders, powdered milk, coal, and other nonmetallic inorganic substances. These materials, when processed, handled, or transported, can generate fine dust that becomes hazardous under the right conditions.

The movements and processing of these materials create dust and, as a result, generate combustible dust and possible dust clouds, creating possible combustible dust explosions. Combustible dust poses a significant risk due to its ability to form explosive dust clouds when suspended in the air, making it crucial to implement preventive measures in industries like woodworking, food processing, metal processing, and agriculture products.

Many hot surfaces are present within the equipment in these industries, acting as an ignition source for possible combustible dust explosions. As a result, combustible dust explosions may occur from distinct particles in the right concentration and are a dust explosion hazard when suspended and in a confined space.

Types of combustible dust, how industries create dust, and how combustible dust explosions happen are provided in more detail:

Woodworking Industry

- Examples: Sawdust, wood shavings, fine wood dust from sanding and cutting.

- Hazards: Fine wood particles can ignite when suspended in air, causing flash fires and explosions. This process creates severe combustible dust hazards and potential combustible dust explosions in sawmills, carpentry shops, furniture manufacturing facilities, and lumber processing plants.

Incident Example: West Fraser Mill Explosion (2022, Scotland, UK)

A conveyor system explosion that epitomized the catastrophic consequences of neglecting dust safety protocols. The incident unfolded in a manufacturing facility where accumulated wood combustible dust on the conveyor belts ignited, resulting in a powerful explosion. The force of the blast caused severe damage to the infrastructure, injuring multiple workers and leaving a cloud of uncertainty in its aftermath.

The incident underscored the critical importance of rigorous dust management practices and the need for comprehensive risk assessments to mitigate such dust explosions.

Agriculture Industry

Agricultural activities and agricultural products involving grain handling, storage, and processing generate combustible dust materials, in sufficient quantities, particularly from grains and solid–composed materials such as egg whites.

- Examples: Grain dust (wheat, corn, rice, soybeans), flour dust, egg white powder. Grain dust is generated in sufficient quantities in Silos, grain elevators, grain processing plants, and feed mills, creating potential grain dust explosions when suspended in air. Flour dust is generated in Bakeries, flour mills, and pasta production facilities.

- Hazards: Silos, grain elevators, and confined spaces create high risks for grain dust explosions.

Incident Example: DeBruce Grain Elevator Explosion (1998, Kansas City, USA)

Grain dust ignited, causing multiple fatalities and emphasizing the importance of dust management in grain handling facilities.

Food Processing

- Examples: Sugar, flour, powdered milk, spices, cocoa powder, egg whites, pet food, spices, and powdered additives commonly used in food production and food processing as by-products.

- Hazards: Accumulated dust in bakeries, food production plants, and sugar refineries can ignite, leading to explosions due to the presence of airborne particles during screening dry materials, production, and packaging processes.

Incident Examples:

Imperial Sugar Company Explosion (2008, Georgia, USA) – A sugar dust explosion caused fatalities and widespread facility damage.

Grain dust explosion at a pet food manufacturing plant at the Flagstaff, Arizona Nestle Purina plant (September 14, 2014) – This was caused by welders conducting hot work repairs on the facility’s grain elevators. The interior of the bucket elevators was not sufficiently cleaned of combustible grain dust materials prior to performing the work, creating a combustible dust hazard.

Cocoa powder: Cocoa powder is a prime example in the food industry that can generate a combustible dust hazard and cause dust explosions. Chocolate factories and beverage production facilities that handle cocoa powder face the risk of dust explosions. Cocoa powder particles, when dispersed in the air, can become highly flammable. Stringent cleaning protocols, dust collection systems, and spark detection systems are crucial safety measures in such settings to prevent dust explosions.

Spices: Spice processing facilities create various powdered spices and solids materials composed of paprika, pepper, and cinnamon, which can create examples of combustible dust materials. The grinding and milling processes involved in spice production can generate fine particles that, if not managed properly, could lead to dust explosions. Implementing protection measures like venting, containment systems, and proper equipment maintenance is vital in these facilities to prevent a dust cloud, a combustible dust hazard, and a dust explosion.

Chemical Manufacturing

Various chemical compounds in powdered or fine particulate form can be combustible.

- Examples: Coal, sulfur, pharmaceutical powders, dyes, and pigments.

- Hazards: Certain chemical dusts are not only flammable but can also react dangerously when exposed to heat or sparks. These materials often pose additional challenges and chemical safety due to their chemical reactivity and the potential for toxic byproducts during combustion. Managing chemical dust hazards and chemical safety is crucial in industries such as chemical manufacturing, mining, and energy production.

Incident Example: Concept Sciences Explosion (1997, Allentown, Pennsylvania, USA) – An explosion at the Concept Sciences chemical plant was caused by the ignition of a cloud of dust generated during the manufacturing of specialty chemicals. The explosion resulted in fatalities and highlighted the risks associated with dust in chemical processing.

Biosolids: Biosolids from wastewater treatment plants and organic waste processing can also present a dust hazard. Combustible dust explosions happen when the buildup of dried residue from the processing of wet materials generates dusts. The dried residue and processing of these organic materials can create examples of combustible dust as fine particles that, under certain conditions, become combustible. Effective dust control methods, ventilation, and stringent safety protocols are imperative to minimize the risk of dust explosions in these environments.

Metalworking Operations

Metal dust from grinding, abrasive blasting, cutting, or polishing operations is another significant hazard that generates dusts and may accumulate above suspended ceilings.

- Examples: Aluminum, magnesium, steel dust. Metal dust comprises tiny particles of metals like aluminum, zirconium, and magnesium. These metals are known for their combustible nature, especially when reduced to fine dust. Aluminum dust is generated in Aircraft, metal processing facilities, recycling facilities, and automotive manufacturing facilities from grinding, abrasive blasting, cutting, or polishing. Magnesium combustible dust is generated in Metalworking shops and fireworks manufacturing from grinding, abrasive blasting, or cutting, which may cause dust cloud suspended in the air.

- Hazards: Metal dust suspended in the air can cause powerful explosions, especially in confined spaces. The ignition of metal dust can result in intense fires and explosions, making proper containment and control imperative in industries like metalworking and aerospace manufacturing. Process equipment and electrical equipment in these facilities add an additional ignition source for explosions, and combustible dust explosions happen in time.

Incident Example: The Hoeganaes Corporation Plant Explosion (2012, Tennessee, USA) – The explosion, caused by the ignition of metal dust from powdered iron, resulted in fatalities and emphasized the risk of combustible dust in metal manufacturing processes like grinding, welding, and cutting.

Plastics and Rubber Processing

- Examples: Fine dust particulates and fine plastic powder, produced during processing with solid organic materials.

- Hazards: Facilities engaged in molding, extrusion, or recycling these examples of combustible dust material face the risk of explosions when suspended in the air.

Incident Example: Jasper Rubber Plant Explosion (2015, Jasper, Indiana) – Jasper firefighters battled super-heated flames while contending with freezing gear when a dust bin collection system at a Jasper Rubber plant caught fire.

Textile Industry

- Examples: Cotton fibers, synthetic fibers, and textile dust generated during manufacturing processes.

- Hazards: Spinning, weaving, and finishing operations in textile mills can generate dusts, and create hazardous combustible dust concentrations, when suspended in air. Textile processes involving spinning, weaving, and cutting can generate lint and fibers that, when accumulated, pose a serious combustible dust risk.

Incident Example: The Malden Mills Factory Fire (1995, Massachusetts, USA) – The fire, fueled by accumulated lint and dust from synthetic fibers, led to a massive blaze that destroyed a significant portion of the factory.

Synthetics

- Examples: Polyester, nylon, and other artificial fibers used in apparel manufacturing.

- Hazards: The synthetic fiber production process involves handling materials that can create combustible dusts and dust explosions. Different types of Fibers such as nylon, polyester, and rayon, can generate fine particles during their processing, especially during cutting, grinding, or handling of raw materials and can be explosible in dust form. The buildup of dried residue from the processing of wet materials can also generate dusts. Proper ventilation, dust collection systems, and regular cleaning are crucial in minimizing the risk of explosions in these manufacturing facilities.

Pharmaceutical Manufacturing

- Examples: Powdered medications and ingredients,

- Hazards: Pharmaceutical production can form combustible dusts, necessitating strict safety protocols to prevent potential explosions.

Incident Example: West Pharmaceutical Services Explosion (2003, Kinston, North Carolina, USA) – An explosion occurred at the West Pharmaceutical Services plant due to a dust cloud ignited by static electricity during the production of rubber components for pharmaceutical packaging. The blast claimed the lives of six workers and injured many others.

Mining Industry

- Examples: Dust from activities such as drilling, blasting, material handling, and screening dry materials.

- Hazards: Combustible dust incidents in mines have occurred due to the accumulation of fine particles of solid material from coal, metal ores, and other minerals. These incidents often involve combustible dust as a hazard when suspended, triggered by the ignition of accumulated dust, from solid organic materials, leading to devastating consequences.

Incident Example: The Upper Big Branch Mine disaster (2010, West Virginia) – A buildup of coal dust caused an explosion that claimed the lives of 29 miners.

Coal and Power Generation Plants

- Examples: Combustible solid organic materials and byproducts

- Hazards: The production, processing, and combustion of coal as a solid material generate fine coal dust particles that, when suspended in the air, can lead to a potential combustible dust explosion. Power plants that use coal as a fuel source also face the risk of combustible dusts. These power plants combust coal to produce steam, which drives turbines to generate electricity. During the combustion process, coal dust may accumulate in various areas of the plant, including coal handling systems, coal storage areas, conveyors, pulverizers, and boiler rooms, which generates dust, and causes a dust cloud and dust explosion.

By recognizing the distinct characteristics and risks associated with these types of combustible dust, businesses can implement tailored safety measures, including combustible dust control, chemical safety, ventilation, and employee training, to mitigate the potential for combustible dust-related incidents. Combustible dust explosions happen in manufacturing facilities all over the world.

Prioritizing occupational safety and health not only protects workers but also ensures occupational safety compliance with regulatory standards with the National Fire Protection Association and the US Occupational Safety and Health Administration (OSHA), ultimately safeguarding the integrity of your operations from combustible dust explosions.

Managing combustible dust starts with proper knowledge.

The Science of Combustible Dust

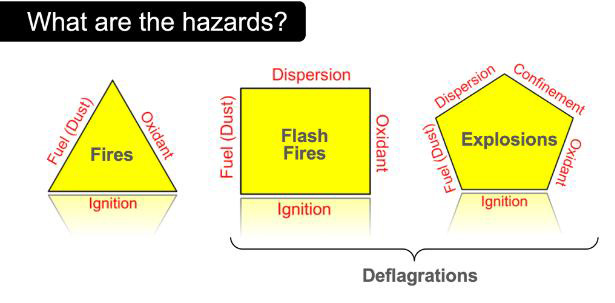

The Combustion Triangle, Square, and Pentagon

A dust explosion occurs when five key elements, known as the “Dust Explosion Pentagon,” are present:

- Fuel (Combustible Dust): Fine particles suspended in the air.

- Oxygen: Airborne oxygen acts as an oxidizer.

- Ignition Source: Sparks, heat, or flames.

- Dispersion: Dust must be airborne in sufficient concentration.

- Confinement: Enclosed spaces intensify the explosion pressure.

Dangers of Combustible Dust

Health Risks

Exposure to combustible dust not only poses significant fire and explosion risks but also presents serious health hazards to workers. Common health risks include:

- Respiratory Issues – Inhalation of airborne dust from agricultural products like flour dust, powdered milk, and grain dust can cause coughing, irritation, pneumoconiosis, and chronic obstructive pulmonary disease (COPD).

- Toxic Exposure – Certain dust types, such as metal or chemical dust, may contain toxic substances that cause acute or chronic poisoning.

- Skin and Eye Irritation – Direct contact with dust particles can lead to rashes, redness, and irritation.

To mitigate these risks, industries should implement:

- Robust dust control measures

- Adequate personal protective equipment (PPE)

- Health administration training and awareness programs

Prioritizing worker safety aligns with best practices in combustible dust safety and promotes a responsible business culture.

Safety Risks

Combustible dust explosions are a major safety concern across industries. Key hazards include:

- Fire Hazards – Dust particles suspended in the air can ignite rapidly, leading to intense fires.

- Explosion Hazards – A spark or heat source can trigger a dust explosion, causing severe damage.

- Structural Damage – Shockwaves from explosions can destroy buildings, leading to secondary fires and casualties.

To reduce these risks, businesses must implement comprehensive dust management strategies, including:

Real-World Incidents

Combustible dust explosions have occurred over the last century. Real-world incidents involving combustible dust have left a trail of destruction and underscore the critical importance of proactive safety measures.

Several incidents highlight the dangers of combustible dust:

- Sugar Refinery Explosion (2008) – A massive dust explosion at a sugar refinery caused multiple fatalities and extensive damage.

- Grain Elevator Explosion (2011) – Combustible grain dust ignited, leading to tragic consequences.

These cases emphasize the importance of proactive dust management and regulatory compliance to prevent similar disasters.

By examining these real-world examples, businesses can better grasp the gravity of combustible dust risks and take measures to prevent such devastating combustible dust hazards and incidents.

Ensure your team is equipped to prevent and manage the dangers of combustible dust.

How to Manage Combustible Dust Safely

Dust Hazard Analysis (DHA)

A Dust Hazard Analysis (DHA) is a systematic evaluation that:

- Identifies and assesses combustible dust risks in various industrial settings

- Examines processes, equipment, and materials that generate dust

- Ensures compliance with NFPA 654 regulations and OSHA guidelines

DHA plays a crucial role in workplace safety by mitigating explosion risks and implementing preventive measures.

Prevention Measures

Prevention measures are the foundation of effective combustible dust management, and they are also vital for combustible dust safety strategies. To mitigate the risks associated with dust, implementing proactive techniques is essential.

Dust Collection Systems

Combustible Dust collection systems are among the most crucial tools in this endeavor. These systems capture and remove dust particles from the air, preventing combustible particulate solids and dust accumulation, the formation of explosive dust clouds, and an explosion hazard.

Implementing effective combustible dusts control measures is crucial to prevent combustible dusts suspended in the air. Examples of a control measure include the following:

- using dust suppression techniques

- enclosing conveyor systems

- capturing combustible particulate solids

- employing dust collection systems

- identifying an explosion hazard

- regular cleaning to minimize dust accumulation in sufficient quantities in a confined space or a suspended ceiling

Proper Ventilation

Ensuring adequate ventilation in coal handling areas and processing plants helps disperse dust particles, safely vent dust particles, and prevent the accumulation of explosive concentrations.

Ignition Source Prevention

Eliminating a potential ignition source and also controlling ignition sources, such as sparks from equipment, static electricity, open flames, or hot surfaces, is essential to reduce the risk of ignition.

Training and Safety Protocols

Comprehensive training for employees on dust control practices, emergency procedures, and the importance of maintaining a dust-free environment is critical.

Explosion Protection Systems

Installing explosion suppression and isolation systems, as well as using spark detection and extinguishing equipment, can help mitigate a deflagration hazard and the impact of potential dust explosions.

Regular Inspections and Maintenance

Conducting routine inspections, maintaining equipment in good condition, and promptly addressing any issues related to dust control and safety are essential dust explosion preventive measures. These inspections should encompass various critical components such as:

- dust collection systems

- equipment in a confined space

- a suspended ceiling

- plenum spaces

- ventilation systems

Regularly assessing the condition of these systems, checking for wear and tear, processes that generate combustible particulate solids and dusts, and ensuring they are in optimal working order is paramount.

Moreover, conducting combustible dust hazard analyses at regular intervals to identify evolving risks is crucial. By prioritizing these maintenance and inspection practices, businesses not only enhance workplace safety but also convey a commitment to responsible practices, which resonates positively with the employees.

Emergency Preparedness

Emergency preparedness, with a safety hazard investigation board and team, is a critical aspect of safeguarding your business against the potential devastation of combustible dust explosions while also aligning with combustible dust hazard best practices.

To effectively respond to such incidents, it’s essential to have a well-defined emergency plan in place. This plan should encompass the installation and accessibility of emergency equipment such as fire extinguishers, sprinkler systems, and explosion venting devices.

Equally vital is the provision of comprehensive health administration training for employees, ensuring they are well-versed in emergency procedures, evacuation routes, and the proper use of safety equipment. By prioritizing emergency preparedness, businesses not only protect their workforce and assets but also send a clear message of responsibility and safety to their employees.

Conclusion

This guide on examples of combustible dust has explored:

- The health and safety risks associated with combustible dust

- Real-world incidents demonstrating the dangers

- Best practices for managing and preventing combustible dust hazards

Understanding and managing combustible dust is not just about regulatory compliance—it’s about safeguarding lives, assets, and the environment. Businesses that prioritize safety through proper dust hazard analysis, prevention measures, and emergency preparedness can significantly reduce risks and create a safer workplace.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust Hazard information, with a Podcast. Click on the latest Podcast Link: What is Combustible Dust and Combustible Dust Hazards.

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art fire and explosion protection.