Updated November 28, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is a Dust Explosion?

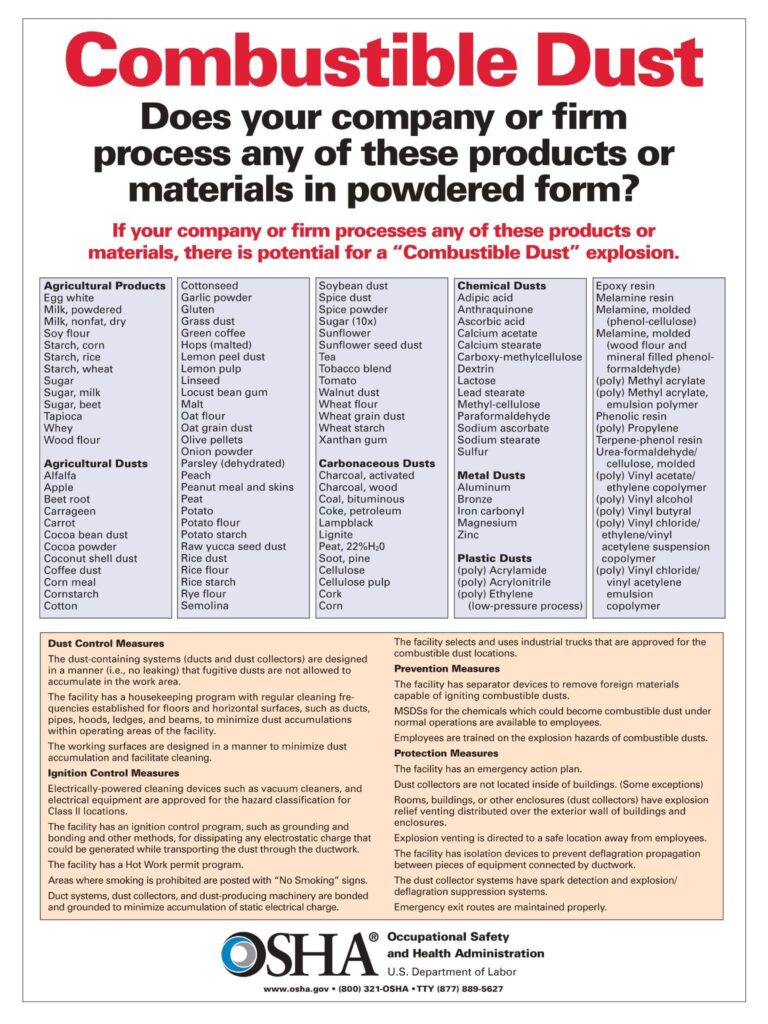

Combustible dust explosions are violent and often devastating events that occur when fine, dry, particles of combustible materials become suspended in the air and then ignite, and catch fire, leading to a rapid release of energy. Dust particle size influences any explosion. The fire triangle key three elements necessary for an explosion include fuel (the combustible dust), oxygen (present in the air), and ignition sources (typically a spark, open flames, static electricity, or even hot surfaces). The addition of small particle dust dispersion in a confined space, generates the Five factors (oxygen, heat, fuel, dispersion, and confinement) are known as the explosion pentagon. If one element of the pentagon is missing, an explosion cannot occur. Source: OSHA Combustible Dust Explosion

The primary explosion process that leads to a an explosion involves the dispersion of dust particles in the air, the creation of a dust cloud, ignition source, and the subsequent rapid combustion of the cloud, which results in pressure waves, fireballs, and potential damage. Source: https://www.nfpa.org/codes-and-standards/6/5/4/nfpa-654

This initial explosion and combustion process is called deflagration and produces a high-pressure airwave. As the airwave bursts from its enclosed space, it is likely to displace or stir up build up dust and dust particles in a high surface area of the manufacturing facility, such as a dust collector and dust collection system, roof trusses and beams, suspended ceilings, confined spaces and enclosed spaces, other dust collectors, electrical equipment, and HVAC ductwork ventilation systems. This explosion pentagon process will mix the dust with the oxygen in the air, intensifying the explosion with a flash fire, and pressure wave, and potentially fueling a secondary or several explosions. Source: https://www.sciencedirect.com/topics/chemical-engineering/dust-explosion

Some of these secondary explosions may occur inside other production or processing machines, and on pipes and beams along a high surface area, with a build up of dust and dust accumulation, creating a possible dust cloud, as the pressure wave and fire propagate through the entire manufacturing facility. Knowledge of the explosion pentagon is the key strategy, with dust accumulations and fugitive dust as an explosion hazard, and an ignition source such as an electric panel, to prevent primary and secondary explosions. At this point from the secondary explosions, the risk of harm to human life, equipment, or entire buildings is catastrophic. Source: https://en.wikipedia.org/wiki/Dust_explosion

What industries are affected by Dust Explosions?

Dust explosions occur in many industries worldwide, which create and produce the threat of combustible dusts, but certain sectors are particularly susceptible to this hazardous concern. Understanding the industries, even materials in the bulk form need to be identified for hazards, affected by dusts as fine particles suspended in air, and explosions is vital for proactive risk management, and to prevent explosions.

A wide variety of industries are affected, and solid organic materials are produced and creates dust including:

- Agriculture

- Food Processing

- Wood and paper products

- Textiles and clothing industries

- Pharmaceuticals

- Furniture Manufacturing

- Metal processing

- Rubber Manufacturing

- Chemical manufacturing

- Recycling operations

- Pulp and Paper Industries

- Polymer and Plastic Manufacturing

- Automotive and Aerospace manufacturing

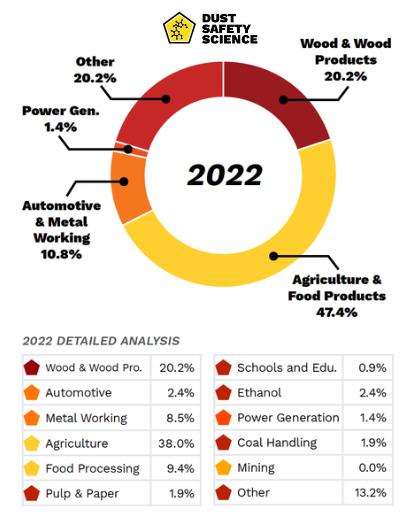

Regarding statistics, industries, industrial processes, process equipment, and dust explosions, the US Chemical Safety Board, CSB, released its Combustible Dust Hazard Study that summarized 281 major explosions between 1980 and 2005 in the United States (CSB, 2006). Among the list of industries most prone to combustible dusts issues are woodworking and sawmills, where wood dust is prevalent, agricultural products, food processing, and grain handling facilities and grain silos, where grain dust explosions, sugar and flour dust pose significant risks. Grain dust explosions are extremely common in agricultural facilities. Chemical manufacturing facilities handling materials like coal dust and sulfur are also at high risk. The metalworking industry, and recycling operations dealing with aluminum and magnesium, must remain vigilant. Agriculture and grain handling, feed mills, grain elevators, pharmaceutical production, recycling facilities, and many others also contend with dust form explosion challenges. Source: Dust Safety Science Combustible Dust Incident Report

In 2023, understanding the materials most frequently implicated in explosions and dust fires is crucial for workplace safety. Dusts and materials like food, metals, grain, and wood can all present significant risks if not handled properly. These materials resulted in 82% of the injuries and 52% of the fatalities. Source: Dust Safety Science Combustible Dust Incident Report

Coal was the most deadly material, accounting for 44% of this year’s fatalities. In reviewing the global incident data, food and wood products made up 79% of the dust fires and explosions recorded. Source: Dust Safety Science Combustible Dust Incident Report

In 2023, The largest fatal Combustible Dust Explosion occurred on March 14, 2023, in Sutatausa, Cundinamarca, Colombia, resulting in 21 Fatalities, which accounted for 44% of the fatalities: 21 Miners Killed in a Coal Dust Explosion (Sutatausa, Cundinamarca, Colombia) Source: Dust Safety Science Combustible Dust Incident Report

On 1 January 1, 2023, a Dust Explosion, at Jindal Poly Films, had a Boiler explosion and had 17 injuries. This incident resulted in 24% of all total, dust injuries: 17 Workers were Injured during a Dust Boiler Explosion (Nashik, India) Source: Dust Safety Science Combustible Dust Incident Report

In the year 2023, industries like wood processing, grain and food production, and metal manufacturing continue to be at the forefront of explosions and dust fires. Industries such as wood, food, and metal processing are among the most common sectors prone to dust form explosions and dust fires. Source: Dust Safety Science Combustible Dust Incident Report

Understanding the risk factors associated with dusts in these industries is crucial for ensuring workplace safety and preventing an explosion. As shown in the historical data (see the full report), wood processing, wood products, agricultural activity such as grain dust, grain dust hazards, grain dust explosions, and food production comprise a large portion of the overall fire and explosion incidents, where dust form explosions occur. Since 2017 wood and wood products have ranged from 19% to 28% of the incidents, while agricultural activity and food production have ranged from 33% to 50%. In addition, several types of dust explosions occurred in West Virginia, including coal and titanium. Source: Dust Safety Science Combustible Dust Incident Report

Conclusion

Understanding the many factors of why combustible dust explosions happen, with prevention measures for combustible dusts and preventing primary dust explosions and a secondary explosion is an ongoing and crucial endeavor for industries and manufacturing processes worldwide. Some of the requirements for combustible dust incidents are the minimum explosive concentration (MEC) for grain dust, grain flour, or ground feed ingredients varies according to the particle size (smaller particles are more powerful). An explosion may occur when the Minimum Ignition Energy, (MIE), is the minimum amount of energy required to ignite a dust cloud when the air-fuel mixture is within its explosible range. Safety compliance and a proactive approach are imperative, as these measures protect lives, serious damage to buildings and assets, and the environment. Even materials in bulk form need to be identified for hazards.

In addition, proactive measures to prevent combustible dust incidents, dust and a dust cloud are a top strategy, to prevent any explosion hazard, initial explosion and secondary dust explosions. In addition, identify when certain dusts, as very small particles suspended in air, or some other oxidizing medium, come into contact with a spark, metal ember, cigarette butt, or other ignition source. Primary and secondary explosions often are so close together that they may be heard as one explosion or a series of explosions. Several types of dust explosions occurred in West Virginia, including coal and titanium, requiring extra dust hazard analysis. By staying informed on combustible dusts, nonmetallic inorganic materials, most solid organic materials, and any combustible material, while adopting best practices, and increasing dust awareness and explosion prevention, organizations can effectively reduce the risk of combustible dust incidents. Combustible dust incidents include the hazards of dust suspended in air as particulate clouds, flash fires, and primary and a secondary dust explosion in an enclosed space, and contribute to safer workplaces globally.

Sources and References

Here is the list of sources and references that can be consulted for further information on dust explosions and combustible dust:

Chemical Safety Board (CSB) website: “Combustible Dust Safety,” https://www.csb.gov/recommendations/mostwanted/combustibledust/#:~:text=In%202006%2C%20after%20investigating%20three,and%20extensively%20damaged%20industrial%20facilities

Dust Safety Science 2023 Incident Summary: https://dustsafetyscience.com/combustible-dust-incident-report/

NFPA 652: Standard on the Fundamentals of Combustible Dust, National Fire Protection Association, 2019 Edition https://www.nfpa.org/codes-and-standards/6/5/2/nfpa-652

NFPA 654: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, National Fire Protection Association, 2020 Edition https://www.nfpa.org/codes-and-standards/6/5/4/nfpa-654

Occupational Safety and Health Administration, (OSHA), website: “Combustible Dust: An Explosion Hazard,” https://www.osha.gov/combustible-dust

Occupational Safety and Health Administration, (OSHA), website: “Combustible Dust Poster,” https://www.osha.gov/sites/default/files/publications/combustibledustposter.pdf and “Safety and Health Topics: Combustible Dust,” https://www.osha.gov/combustible-dust

ScienceDirect, “Dust Explosion – Dust explosion propagation through ductwork connected to a process vessel,” https://www.sciencedirect.com/topics/chemical-engineering/dust-explosion

Wikipedia, Wikimedia Foundation, Inc., website: “Dust Explosion,” https://en.wikipedia.org/wiki/Dust_explosion

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust information, with a weekly Podcast. Click on the latest Podcast Link: Combustible Dust and Combustible Dust Explosions

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.