Updated September 18, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A picture of a Combustible Wood Dust Fire and Hazard, inside a Wood Pallet Manufacturing Facility

Key Takeaways:

- Industry Dynamics: The wood and woodworking industry, crucial in various sectors, confronts a latent dust explosion hazard in the form of combustible wood dust generated during wood processing, cutting, and shaping. In addition, dust collectors may accumulate wood dust, causing additional hazards.

- Hazards of Wood Dust: Wood dust, composed primarily of wood fibers and sawdust, presents a significant risk due to its combustible nature when suspended in the air. Factors like particle size, moisture content, and exposure to ignition sources contribute to its potential for rapid combustion.

- Industry Specific Concerns: Woodworking equipment and processes generate substantial wood dust quantities, posing a dust suspension and accumulation risk. Additionally, the potential for spontaneous combustion of wood piles, wood dust, or sawdust adds to the hazard, demanding stringent preventive measures and proactive risk management strategies.

Understanding the Combustible Dust Hazards, in the Wood and Woodworking Industry

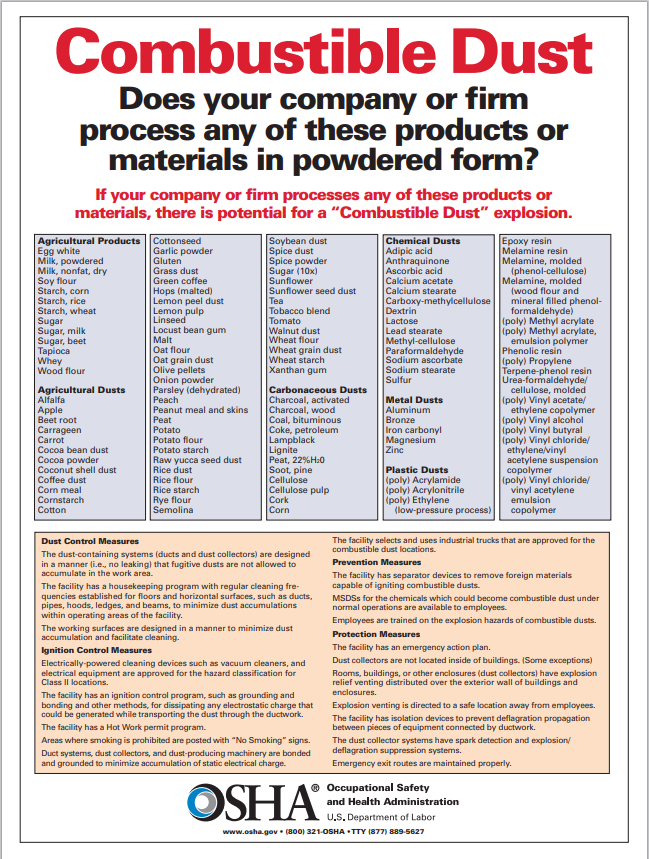

The wood and woodworking industry stands as a cornerstone of construction, manufacturing, and various consumer goods, shaping our everyday lives in multifaceted ways. However, wood dust creates an explosion hazard, with accumulated dust, which can form a dust cloud, from dust particles, causing potential explosions and a serious fire. The Occupational Safety and Health Administration, (OSHA), identifies Wood Dust as a Combustible Dust. Fine particles generated during various stages of wood and woodworking processing, such as sawing, cutting, and routing, and captured by dust collectors, constitute the primary source of combustible wood dust in these facilities, and a possible dust explosion.

From lumber used in construction to paper products and furniture, this industry plays an integral role in global economies. The forest product industry and the lumber industry are also included in the wood and woodworking industry and also present the same combustible dust hazards. However, within the bustling machinery and sawdust-filled workshops of this sector lies a potential dust explosion hazard that demands attention: combustible dust. Understanding the correlation between wood and combustible dust is paramount in safeguarding against potential catastrophes within this dynamic industry. Source: Combustible wood dust explosions and impacts on environments and health – A review

The wood and woodworking industry generates dust as a byproduct of the processing, cutting, shaping, and sanding of wood materials, creating small particle size dust, and as a result, an explosion hazard, with a dust cloud. These fine particles, predominantly composed of wood fibers, sawdust, and other organic matter, pose a significant hazard due to their combustible nature. As wood is cut or shaped, these wood dust particles become airborne, forming a dust cloud, with increased surface area, creating an environment ripe for the accumulation of combustible wood dust.

The accumulation of this particle size wood dust, often unnoticed in nooks, corners, or within machinery such as dust collectors, creates an environment primed for potentially dust explosions. These wood dust particles, when suspended in the air as a dust cloud, at specific concentrations and exposed to ignition sources such as sparks, electrical equipment, dust collectors, or even hot surfaces, increase in surface area, and can result in rapid combustion, leading to fires or combustible dust explosions. In addition, inhalation of particle size wood dust is hazardous for public health and safety.

The combustibility of wood dust is influenced by various factors, including particle shape, in addition to particle size, which are important material properties affecting dust explosibility, along with moisture content, and typically atmospheric oxygen. Finely ground dust particles are more prone to suspension in the air, creating a combustible mixture. Additionally, the hygroscopic nature of wood dust, which is capable of absorbing moisture, can affect its combustibility. The potential for fire or explosion within woodworking facilities, sawmills, or wood manufacturing necessitates a comprehensive understanding of these dust explosion hazards and the implementation of stringent safety protocols.

Understanding dust explosions associated with wood dust in the wood industry requires recognizing its inherent combustible properties. The organic nature of wood, when transformed into fine dust particles, amplifies the risk potential for a serious fire and catastrophic loss. The flammable nature of wood dust, coupled with its ability to disperse and suspend in the air, underscores the critical need for stringent safety measures and proactive risk mitigation strategies, for preventing wood dust explosions.

A picture of the NFPA 664 Standard for the Prevention of Fires and Explosions in Wood and Woodworking Facilities

Wood and Woodworking Industry Specific Concerns and Root Causes with Dust

In the wood and woodworking industry, specific equipment and operational processes elevate the combustible wood dust explosion risks associated with combustible wood dust. Equipment such as saws, planers, sanders, and dust collection systems generate considerable amounts of wood dust during woodworking operations. The fine nature of this particle size dust, combined with the high-speed machinery used, creates combustible materials and increases the probability of dust suspension in the air. Moreover, inadequate maintenance or improper handling of dust collectors, dust collection systems, and dust extraction systems can lead to dust buildup of combustible materials, amplifying the potential for hazardous dust explosion incidents and serious fire hazards.

Similar to grain bins in the grain and agriculture industry, spontaneous combustion can be a concern in the woodworking and wood sector. Piles of wood chips or sawdust, if left undisturbed and subjected to high temperatures due to microbial activity or chemical reactions, can smolder and contribute to the accumulation of combustible dust. These factors underscore the critical need for rigorous preventive measures and continuous risk assessments to ensure the safety of workers and facilities within the wood and woodworking industry and dust explosions.

Regulations and Standards for Preventing Explosions

Regulations, Standards, and Codes allow for guidance on preventing dust explosions in wood and woodworking manufacturing facilities The National Fire Protection Association, NFPA 664 Standard is for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities. This standard provides requirements for explosion prevention and protection of industrial, commercial, or institutional facilities that process wood or manufacture wood products to protect life, and property, and prevent a catastrophic loss from a secondary explosion. The Occupational Safety and Health Administration, (OSHA), identifies Wood Dust as a Combustible.

The NFPA 652, Standard on the Fundamentals of Combustible Dust, serves the chemical, wood, metals, and agricultural industries. NFPA 652 directs users to NFPA’s appropriate industry– or commodity-specific standards, which include:

- NFPA 61, Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

- NFPA 484, Combustible Metals

- NFPA 654, Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids

- NFPA 664, Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities

The NFPA is also working on a consolidated NFPA 660 Standard for combustible dust.

Statutory Agency, Council, Institution, and Codes for Preventing Explosions

Several organizations in British Columbia and Canada, have different types of Building codes and standards, to prevent the catastrophic loss, of wood dust. According to WorkSafeBC, the authors declare airborne wood dust presents an exposure hazard to workers. Activities likely to produce high wood dust levels include:

- Machining operations, particularly sawing, routing, and sanding

- Using compressed air to blow wood dust off furniture or equipment

- Emptying the bag from a dust extraction system or vacuum

The BC Fire Code defines combustible wood dust as “dust and particles that are ignitable and liable to produce an explosion.”

The Canadian Wood Council (CWC) is the national federation of forest product associations. The Canadian wood industry devotes considerable resources to fire research programs to improve the understanding of the performance of wood products in fire. This fire research will be used to support a Canadian approach to a worldwide trend toward building codes based on performance instead of prescriptive requirements.

Addressing combustible wood dust concerns in the wood and woodworking industry requires a multifaceted approach that acknowledges the industry’s unique challenges and root causes. From the inherent combustibility of wood particles to the presence of fine wood dust generated during various woodworking processes, understanding these specific concerns is crucial for implementing effective preventive measures, for dust explosions. By prioritizing comprehensive training, equipment maintenance, and adherence to strict safety protocols, per standards and regulations, such as the NFPA 664 Standard, and the NFPA 652 Standard, businesses in this sector can mitigate the risk of dust incidents and ensure the safety of their workers, fire crews, and facilities.

Continuous effective proactive safety measures, in managing dust hazards will foster a safer work environment within the wood and woodworking industry. Additionally, dust explosion prevention and protection is provided by the Institution of Chemical Engineers.

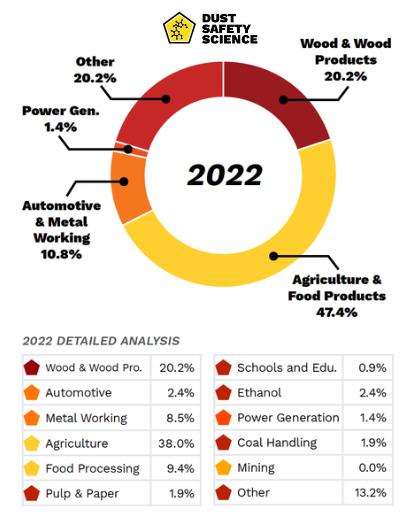

A picture of a detailed analysis and percentages of several Industries, including Wood and Wood Products, affected by Combustible Dust, from Dust Safety Science

Historic Wood and Woodworking Industry Related Combustible Dust Explosions

Combustible dust incidents, continue to occur worldwide and in the Wood and Woodworking industry, as presented in this combustible dust research and incident database from Dust Safety Science. In addition, statistics of the most prevalent industries, regarding combustible dust incidents, are also captured in this Annual Incident Report Database, from Dust Safety Science. In 2022, the Wood and Woodworking Industry had 20.2% of combustible wood dust incidents. In addition, the Dust Safety Science Podcast educates the public on Safety Share – Explosion at Wood Pellet Receiving Port. Some of the historic Wood and Woodworking Industry dust explosions and incidents include:

- The Great Boston Fire (1872): According to Wikipedia, One of the most infamous fires in American history, the Great Boston Fire of 1872 was fueled in part by a combination of dust from Woodworking industries, manufactured Dry Goods, and Gunpowder. The fire started in a basement on Summer Street and quickly spread due to the abundance of wood structures and wooden mansard roofs, as they were a common architectural trend of the time. In addition, the warehouses stored Dry Goods in the eaves of the roofs, as additional sources of dust. This dust, generated from various stored goods such as flour, sugar, textiles, and cotton, fueled the fire. The heat became so intense that the stone facades shattered. As the fire spread, citizens asked Mayor William Gaston to authorize the use of gunpowder to blow up buildings in the path of the fire to create a firebreak. Mayor Gaston approved the creation of firebreaks and groups of citizens began packing buildings with gunpowder kegs. However, the firebreaks were not effective. Instead, they caused injury to the citizens involved and the flaming debris from the exploded buildings spread to surrounding buildings. Eventually, Damrell had to force citizens to stop using gunpowder. The fire ravaged over 65 acres of the city and destroyed hundreds of buildings, causing millions of dollars in damage. This tragic event underscored the dangers posed by dust in industrial settings.

- New England Wood Pellet (October 2011): A dust explosion occurred at the New England Wood Pellet manufacturing company. An inspection by OSHA’s Concord Area Office conducted in response to that incident identified numerous fire and explosion incidents stemming from the absence of protective devices, which were exacerbated by a buildup of sawdust on surfaces throughout the plant.

- Lakeland Mills Ltd (April 2012): According to WorkSafeBC, an Explosion and fire occurred at the Lakeland Mills Ltd sawmill, in Prince George. The Investigation conclusions:

- The concentration of dispersed wood dust in the air: The wood dust that was dispersed in the air within the Lakeland sawmill was of sufficient concentration to explode. The wood dust was the fuel for the explosion.

- Friction in the gear reducer provided an ignition source for wood dust explosion: Near the gear reducer was a containment zone created by a high-walled conveyor, a steel-plated ceiling, and an exterior wall.

Historic dust explosions in the wood, woodworking, lumber, and forest products industries provide reminders of the significant dust hazards associated with inadequate dust management practices. These incidents have resulted in tragic loss of life, extensive property damage, and substantial economic repercussions. However, they have also underscored the critical importance of implementing proactive measures to prevent such catastrophes and a second explosion, from wood dust. By drawing lessons from past incidents, adhering to relevant standards such as NFPA 664 and NFPA 652, and prioritizing ongoing training and education, industry stakeholders can fortify safety protocols across the entire spectrum of wood-related operations, and combustible material.

Conclusion

The threat of combustible dust explosions, continues within the wood and woodworking industries, posing significant risks to workers, human health, and facilities. A risk assessment and preventative measures are paramount in mitigating these wood particles, wood dust hazards such as dust clouds, and fire and explosion hazards. Safety measures such as diligent housekeeping practices to the implementation of effective ventilation, dust collectors, and dust control systems, as outlined in standards such as NFPA 664 Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities. Insufficient dust quantities, from proper dust control measures, prevent hazardous conditions.

Additionally, comprehensive training programs are essential to ensure that all personnel are well-informed about the dangers of wood dust accumulation and equipped with the knowledge to recognize potential risks, aligning with guidelines set forth by NFPA 652, Standard on the Fundamentals of Combustible Dust. By addressing root causes such as inadequate maintenance, improper equipment operation, deflagration venting, and insufficient safety protocols, industry stakeholders can foster a culture of safety that prioritizes proactive measures, and prevent catastrophic loss, regarding a wood dust explosion.

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible Wood Dust in the Wood and Woodworking Industry, visit this podcast episode: Grounding and Bonding of Silos Storing Wood Chips with Jeramy Slaunwhite

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.