Updated August 27, 2024 Authored by Chris Cloney

To get an appreciation of the physics of an industrial explosion, it is beneficial to understand the basics of flame dynamics and flame propagation under simplified conditions. This post briefly reviews two models of flame propagation through a gas/air mixture to demonstrate the important system parameters. Future posts will look at the effect of non-premixed flame propagation and turbulence, as well industrial explosion of multiphase (solid/gas/air) mixtures. Readers interested in a more detailed explanation of the fundamental theories for laminar flame propagation and their mathematical derivations, are encouraged to see Chapter 5 in the textbook of Kuo, 2005 from which the following discussion was derived.

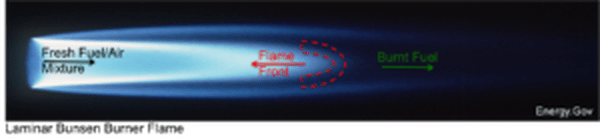

A flame front is a reaction zone which moves through a mixture of fuel and oxidizer, leaving burnt products in its wake. In most industrial cases involving flammable gas the oxidizer is the oxygen molecules from the air, and the gas is used as part of the processing application (e.g., methane, hydrogen, etc.). Inside the flame front the fuel is heated and reacts, providing energy which manifests itself as temperature and light. Once the flame temperature becomes high enough, it can heat the fuel ahead of it to ignition and the flame becomes self-propagating.

The self-propagating feature leads to a standing flame in the Bunsen burner apparatus shown above. The fresh fuel is supplied by a tube to the left of the image and reacts in the flame outer edge. The color, shape, and height of the flame depends on the fuel/air mixture and the inflow velocity. Under industrial conditions a self-propagating flame may continue through the entire area containing the gas cloud, causing destructive temperature and overpressure.

Thermal Theory

The first models of premixed flame propagation were based on the work of Mallard and Le Chatelier, who postulated that heat transfer (specifically thermal conductivity) is the driving mechanism. In their work the flame was divided into two regions: an inert Preheat Zone and a chemically active Reaction Zone. A one-dimensional schematic of this concept is shown in the figure below. In this figure the flame is propagating from right-to-left. Thermal conduction drives heat from the high-temperature reaction zone into the preheat zone. In the preheat zone the fresh propellent is brought to the fuel ignition temperature. At this temperature a chemical reaction will start, converting the fresh propellent to burnt products.

The goal of a flame propagation model is generally to predict two parameters: the maximum flame temperature (\(T_{text{F}}\)) and the laminar flame speed (\(S_{text{L}}\)). The maximum flame thermal reading can be calculated directly from thermodynamics assuming equilibrium between the fuel and reaction products. The laminar flame speed depends on the overall dynamics of the fuel system and the interaction between the physical and chemical processes. From a mathematical description of the system above, Le Chatelier predicted that the flame speed is proportional to the square root of the chemical reaction rate \((RR, text{1/s})\) and the thermal diffusivity of the gas \((alpha, text{m}^{2}text{/s})\), giving the mathematic relation \(S_{text{L}} propto sqrt{RRalpha}\).

Diffusion Theory

A second group of flame propagation models were developed that assume that diffusion of gaseous species, and specifically the intermediate species of the chemical reactions, is the driving mechanism. For example in a hydrogen gas flame the global reaction \(text{H}_{2} + text{O}_{2} rightarrow 2text{H}_{2}text{O}\) occurs, but is actually broken into several intermediate processes including chain-branching and chain-terminating reactions (See Chapter 2 in Kuo 2005 for a description of chemical kinetic mechanisms and their role in combustion). For hydrogen combustion some of these reactions include the intermediate steps: \(text{H}_{2} + text{O}_{2} rightarrow text{H} + text{H}text{O}_{2}\) and \(text{H} + text{O}_{2} rightarrow text{OH} + text{O}\), for example.

The schematic below illustrates the diffusion theory for flame propagation. The y-axis in the figure represents species molar fraction (proportional to the mass of species per unit volume). It is plotted in log scale as some of the intermediate species/radicals are present in very small amounts (e.g., O). However, these intermediate species may have very high mass diffusion rates. Under diffusion theory it is predicted that the movement of these intermediates from the reaction zone to the area ahead of the flame is the driving mechanism. Under the diffusion theory the flame speed can be shown to be proportional to (√) of the sum of the specie mass diffusivities \((mathcal{D}_{i}, text{m}^{2}text{/s})\) multiplied by their partial pressure \((p_{i})\), giving the mathematic relation \(S_{text{L}} propto sqrt{sum({p_{i}mathcal{D}_{i})}}\).

Conclusion

Thermal and diffusion theories represent limiting conditions for flame propagation, and neither fully describes the whole process. In reality both mechanisms occur simultaneously, and several other features such as temperature dependent thermophysical properties, detailed chemistry kinetics, instability formation, and flame stretching may also be important. That being said, these simplified flame propagation models demonstrate three of the major considerations for estimating laminar flame speed and demonstrate the importance of chemical reactivity, thermal diffusivity, and mass diffusivity of flammable gas hazards, in the combustion process.

In the study of flame propagation, models have been developed to predict the behavior of laminar flames during the combustion process. These models analyze how the flame outer edge moves through the air-fuel mixture, taking into account the interactions between a chemical reaction and physical properties like mass, heat, and pressure. A key factor in these models is the laminar flame momentum, which represents the rate at which a flame propagates through a unit volume of the propellent mixture under laminar conditions. As shown in many experimental data, the flame momentum can be calculated and predicted based on the air fuel ratio, temperature, and energy released during ignition. For example, an engine’s combustion chamber may feature specific modes of flame propagation that are proportional to the propellent mixture’s composition and the heat generated during the reaction, and combustion process, directly affecting flame propagation. The flame propagation mechanism is critical to understanding how efficiently energy is transferred during combustion.

The flame propagation model relies on a complex chemical reaction and diffusion processes, where energy is transferred through turbulence and pressure changes inside the combustion structure. As the flame propagates, the interaction between different species of chemical reactants affects the combustion’s efficiency and speed. This article illustrates how flame propagation and the combustion process can be divided into several phases, starting from ignition and continuing with the propagation of the flame outer edge through the fuel-air mixture. The step-by-step analysis provides insights into how the thermal reading and pressure within the combustion chamber increase during this process. A detailed description of the flame model reveals how the flame momentum varies, and how this speed is linked to the √ of the temperature ratio, resulting in changes in the flame’s structure, and impacting flame propagation.

Several experimental models have been published to study and analyze the effects of flame propagation and combustion under various conditions. For example, a flame propagation model can be used to predict how limited air supply or increased turbulence might affect the flame speed in practical applications, such as in engines or industrial combustion systems. A figure shown in this work highlights the differences between laminar and turbulent flames, illustrating the proportional effects of air and propellent, diffusion, and heat transfer on the overall combustion process. In terms of experimental validation, the work of various researchers, such as Smith et al., has found that the propagation model accurately predicts flame behavior under specific conditions, allowing for continued improvements in combustion efficiency, the combustion process, and understanding of flame propagation, and a propagation model.