Updated December 16, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is combustible dust?

Combustible dust refers to finely divided solid particles that are prone to ignition when suspended in the air. These particles can originate from various materials and industries, including agriculture, wood, food, plastic, and chemical processing. This section delves deeper into what qualifies dust as combustible and why it poses a significant dust hazard explosion risk.

Dust qualifies as combustible when it possesses specific characteristics that make it prone to ignition and combustion when suspended in the air, as dust particles. These key attributes include dust particle size, minimum explosible concentration, and chemical composition. Fine particles, often smaller than 420 microns, are more likely to ignite due to their increased surface area.

Additionally, a dust cloud must reach a certain concentration level in the atmosphere with a process specific oxidizing medium to become combustible. The composition of the dust and dust cloud formation is another crucial factor, as certain materials have inherently flammable properties and may catch fire. Understanding these characteristics is vital for identifying and managing the risks associated with dusts, including a secondary explosion, and ensuring workplace safety and compliance.

Organic dust are derived from natural materials in the finely divided form, such as wood, grains, metal, and plastics. Examples of organic materials as combustible dust materials include sawdust, grains like wheat, corn, rice, and soybeans, flour, sugar, spices, powdered additives, pharmaceuticals, dyes, pigments, aluminum, zirconium, magnesium, polyester, cotton, paper, and coal. Some of the solid material and dust are also considered hazardous materials as an explosion hazard, and have additional hazardous properties, as a health administration may also need to be contacted to identify the additional hazards.

What is a dust explosion?

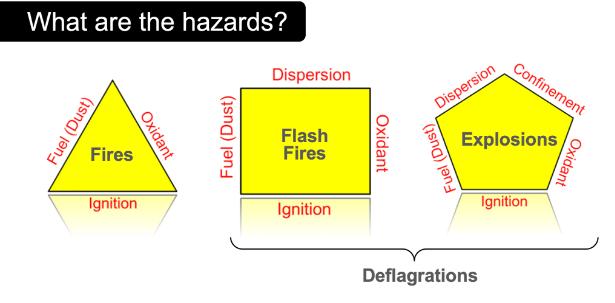

Dust explosions are violent and often devastating events that occur when fine, dry particles of combustible materials become suspended in the air, from dust dispersal, and then ignite, leading to a rapid release of energy. Key three elements necessary and support combustion for an explosion and the fire triangle include fuel (the combustible dust), oxygen (present in the air), and an ignition source (typically ignition sources include spark, open flames, static electricity, or even hot surfaces). Five factors, (oxygen, heat, fuel, dispersion, and confinement), create a dust explosion pentagon. If one element of the pentagon is missing, a primary explosion cannot occur.

The process that leads to a primary dust explosion involves the dispersion of dust in the air, the creation of dust clouds, an ignition source, or a hot surface, the oxygen content in the air, and the subsequent rapid combustion of the cloud, which results in an explosion, pressure waves, fireballs, and potential damage. Combustible dust explosions happen when very small particles in the dust cloud encounters an ignition source, such as static electricity. Primary dust explosions can lead to catastrophic explosions. The force from such an explosion can cause employee injuries, public deaths, and destruction of entire buildings.

This primary combustion process is called deflagration and produces a high-pressure airwave. As the airwave bursts from its enclosed space or a confined space, it is likely to displace or stir up dust accumulation and dust suspended in air in other areas of the manufacturing facility, such as roof trusses and beams, dust collection systems, process equipment, electrical equipment, and HVAC duct ventilation systems. This process will mix the dust with the oxygen concentration in the air, intensifying the explosion and potentially fueling secondary dust explosions or even several.

Some of these secondary explosions and combustible dust fires may occur inside other production or processing machines, with a build up of dust accumulations and ignition sources inside dust collectors, dust collection system, enclosed spaces, or containers, as the pressure wave and fire propagate through the entire manufacturing facility. At this point, the risk of harm to human life, equipment, or even entire buildings is catastrophic, and will cause serious damage, from combustible particles, and a secondary dust explosion. Removing primary explosion characteristics can help prevent explosions.

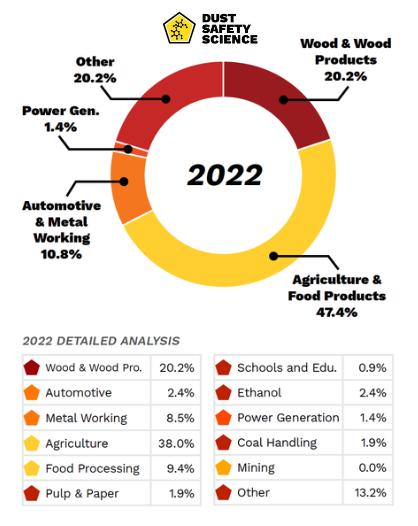

What industries are affected by combustible dust?

Many industries and industrial processes worldwide produce the threat of combustible dust, but certain sectors are particularly susceptible to this hazardous concern. Understanding the industries affected by dust is vital for proactive risk management, and risk assessment, and to prevent additional explosions. Also manufacturing facilities need to address combustible dust hazards, implement preventive measures, and dust explosion prevention, with a dust hazard analysis, and dust standards from the National Fire Protection Association.

Among the full range list of process industries most prone to dust issues and a potential explosion are woodworking and sawmills, where wood dust is prevalent as a dust hazard, and food processing, where grain dust explosions, and sugar and flour dust pose significant combustible materials risks and explosion hazard. Chemical dusts in chemical manufacturing facilities and coal mining industries in Wyoming and West Virginia, handling materials like coal are also combustible dust hazards, and at high risk of coal dust explosions. The metalworking industry, dealing with aluminum and magnesium, must remain vigilant, when preventing a combustible dust explosion and a flash fire. Dust present in agricultural products and grain handling, new materials in pharmaceutical production, even materials in recycling facilities, and many others also contend with dust hazards and explosions.

Conclusion

Understanding dusts, installing explosion protection systems, explosion suppression systems, implementing prevention measures and emergency procedures, and preventing explosions and flash fires, is an ongoing and crucial endeavor for industries worldwide. The extreme importance of occupational safety, compliance, risk assessments, and a proactive approach is imperative, as these measures protect lives, assets, and the environment. Standards and safety measures such as the National Fire Protection Agency, and other industry organizations, should be adhered to, for properly maintained equipment and preventing dust hazards. By staying informed on a new standard, adopting best practices, and increasing dust awareness, and preventing dust dispersion, dust suspension, and prevent dust explosions, organizations can effectively reduce the risk of explosions and contribute to safer workplaces globally.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust information, with a weekly Podcast. Click on the latest Podcast Link: Combustible Dust and Combustible Dust Explosion

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in combustible dust expertise.