The Washburn A Mill explosion highlighted the devastating potential of combustible dust. This tragedy became a turning point in industrial safety, emphasizing the importance of preventive measures in hazardous environments.

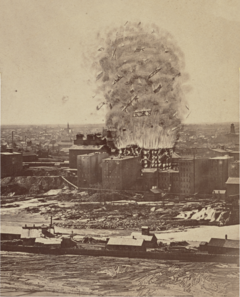

On a quiet evening in 1878, the city of Minneapolis was rocked by a massive explosion. The Washburn A Mill explosion reduced one of the largest flour mills in the world to rubble. The blast shattered windows across the city and left a lasting mark on history.

The explosion in Washburn A Mill was a wake-up call. This huge disaster in the Minneapolis flour milling industry highlighted the deadly potential of accumulated dust—a hazard that still exists today. By understanding the causes and lessons of this historic event, you can take steps to prevent similar disasters in your industry.

Key takeaways:

- Combustible dust, when suspended in the air, poses an often-overlooked explosion risk in industrial settings.

- Regular maintenance and proper dust control systems are crucial in minimizing hazards.

- The Washburn A Mill explosion serves as a case study. It demonstrated how critical it is to adapt and enforce stricter safety regulations.

- Educating workers and industries about the dangers of combustible dust can help prevent similar disasters in the future.

Stay ahead of the risk—invest in training to safeguard lives and prevent combustible dust explosions.

INDEX

The Washburn A Mill Explosion of 1878

What is Combustible Dust?

Lessons From The Tragedy

Preventing Catastrophic Explosions with Dust Safety Science

FAQs

Conclusion

The Washburn A Mill Explosion of 1878

Date and Setting

The explosion occurred on May 2, 1878, at the Washburn A Mill in Minneapolis, Minnesota. At the time, the mill was one of the most advanced flour mills in the world. It was a symbol of industrial progress, producing vast amounts of flour to feed a growing nation.

Cause of the Explosion

The culprit? Flour dust.

Flour may seem harmless. However, in high enough concentrations, it becomes highly combustible. Over time, accumulated dust during flour production builds up in the air and on surfaces inside the mill. All it took was a single spark—likely from ignition sources such as machinery or static electricity—to ignite the dust, triggering a powerful combustible dust explosion.

The initial blast disturbed more dust, leading to a chain reaction of dust explosions. In an instant, the entire mill was engulfed in flames and debris.

Impact of the Explosion

The explosion killed 18 workers instantly. The shockwave leveled surrounding buildings. It sent flaming debris flying through the air, affecting adjacent mills. Fires raged across the city, and the economic impact was devastating.

The destruction of the Washburn A Mill cost millions in damages. It also has disrupted the local economy, affecting jobs and grain supply.

Today, the Washburn Mill stands as a preserved historical site in Minneapolis, Minnesota. The ruins were stabilized and transformed into the Mill City Museum.

The Mill City Museum showcases the history of flour milling and the city’s industrial heritage. Meanwhile, the surrounding area serves as an outdoor event space. The site is a National Historic Landmark. It blends the remnants of the original mill with modern architecture. It’s now a unique educational and cultural destination.

What is Combustible Dust?

Combustible Dust is any fine material catching fire when suspended in the air. Common examples include:

- Flour

- Sugar

- Wood dust

- Coal dust

- Metal dust (like aluminum or magnesium)

The Science Behind Dust Explosions![]()

![]()

For a combustible dust explosion to happen, five key elements must be present, often called the “Dust Explosion Pentagon”:

- Fuel – A cloud of Combustible Dust

- Oxygen – Air, which is always present

- Ignition Sources – Sparks, heat, or flames

- Confinement – Enclosed spaces like factories, mills, or silos

- Dispersion – Fugitive Dust stirred up into the air

The mill exploded as all five elements were present, making the catastrophic event certain after ignition.

Train your team to prevent similar disasters.

Lessons From The Tragedy

The explosion of the largest mill in Minnesota holds profound lessons that transcend time and industry.

1. Dust Hazard Analysis (DHA)

Companies must conduct a dust hazard analysis (DHA) to prevent combustible dust explosions. This systematic process helps identify, assess, and mitigate potential dust-related hazards before they become catastrophic.

A DHA evaluates various risk factors, such as:

- Dust characteristics. Identifying whether the dust is combustible, its particle size, and its minimum ignition energy (MIE).

- Potential ignition sources. Examining equipment, electrical systems, static electricity, and heat sources that could ignite dust.

- Dust accumulation & dispersion. Assessing areas where dust may accumulate, how it disperses into the air, and whether it can form a combustible dust cloud.

- Ventilation & housekeeping practices. Reviewing airflow patterns, dust collection efficiency, and cleaning protocols.

- Preventive & mitigation strategies. Developing strategies to minimize dust hazards. These include proper ventilation, explosion venting, and isolation techniques.

A DHA is required under NFPA 652 and must be reviewed and updated to ensure ongoing compliance and workplace safety.

2. Dust Control Strategies

Implementing effective dust control strategies is crucial for minimizing explosion risks. Here are the key approaches your company can take:

A. Engineering Controls

- Dust Collection Systems. Install high-efficiency dust collectors, such as baghouses and cyclones, to capture airborne dust before it settles.

- Local Exhaust Ventilation (LEV). Use hoods and ducts to remove dust at its source, preventing it from spreading.

- Explosion Venting & Suppression. Install explosion panels or suppression systems to mitigate damage in case of an ignition.

B. Housekeeping Practices

- Regular Cleaning Protocols. Implement a scheduled cleaning routine to prevent dust buildup on surfaces, ducts, and machinery.

- Vacuum Systems. Use industrial vacuums with HEPA filters instead of compressed air, which can disperse dust into the air.

- Inspection & Monitoring. Conduct frequent inspections to detect and address dust accumulation before it becomes hazardous.

C. Ignition Source Control

- Electrical Safety. Ensure that equipment in dust-prone areas meets intrinsically safe (IS) or explosion-proof standards.

- Static Electricity Management. Use grounding and bonding techniques to prevent static discharge from igniting dust.

- Hot Work Permits. Restrict welding, cutting, and other hot work near combustible dust and enforce proper safety procedures.

- Equipment Maintenance. Regularly inspect and maintain machinery to prevent overheating, friction sparks, and malfunctioning components.

By following these proactive dust control measures, your company can significantly reduce the risk of dust-related fires and explosions. It ensures a safer workplace and compliance with NFPA standards.

3. Employee Training

Educating workers is one of the most effective ways to prevent combustible dust explosions. Train your employees on:

- The dangers of combustible dust

- How to spot and control fugitive dust hazards

- Safe work practices to minimize risks

Don’t wait for a tragedy to happen; equip your team with essential combustible dust safety training.

Preventing Catastrophic Explosions with Dust Safety Science

The catastrophic explosion of the Washburn A Mill, along with several adjacent flour mills, was caused by the ignition of airborne flour dust. It truly underscored the critical need for effective combustible dust management in industrial settings.

At Dust Safety Science, we offer comprehensive training programs focused on combustible dust safety and explosion prevention to avoid such disasters.

Training Program Overview:

Our Dust Explosion Safety & DHA Demystified training program is designed to equip professionals with the knowledge and skills necessary to identify, assess, and mitigate combustible dust hazards. The program comprises three key sessions:

1) An introduction to combustible dust and dust explosion hazards

This two-hour introductory class offers a foundational understanding of:

- combustible dust properties

- explosion mechanisms

- associated risks

2) Understanding dust explosion hazard analysis

A four-hour course that delves into methodologies for conducting Dust Hazard Analyses (DHA). It enables participants to systematically identify and evaluate potential dust explosion hazards within their facilities.

3) Understanding dust explosion hazard management

Another four-hour session focusing on the implementation of the following to effectively manage and reduce combustible dust risks:

- engineering controls

- administrative measures

- safety practices

By completing all three sessions and passing the associated assessments, you’ll receive a Combustible Dust Specialist Certificate. This will signify your proficiency in combustible dust safety.

We also offer a custom training program, which gives your company flexibility in terms of content development and delivery. This ensures that you’ll learn safety practices based on your specific industry. Upon completion, you will also receive a certificate of achievement.

Start Your Training – Get Certified Now

Relevance to Preventing Incidents Like the Mill Explosion:

By engaging in Dust Safety Science’s training program, you and your team can:

- Recognize and understand combustible dust hazards. Gain insights into the properties of combustible dust and the conditions that lead to explosions.

- Conduct effective dust hazard analyses. Learn to systematically identify areas and processes within your facilities that are susceptible to dust explosions.

- Implement robust hazard management strategies. Acquire knowledge of engineering controls, proper housekeeping practices, ignition source control, and emergency response planning to mitigate risks effectively.

By applying the principles and practices taught in these courses, industries can significantly reduce the likelihood of incidents akin to the Washburn A Mill explosion, thereby safeguarding lives, assets, and operations.

FAQs

What caused the Washburn A Mill Explosion?

The explosion was caused by accumulated dust (flour dust) ignited by an ignition source, leading to a devastating combustible dust explosion.

What is a Dust Hazard Analysis (DHA)?

A Dust Hazard Analysis (DHA) is a proactive assessment that identifies and mitigates dust-related risks in workplaces to prevent dust explosions.

How can I prevent a combustible dust explosion in my facility?

-

- Implement combustible dust training

-

- Maintain proper housekeeping

-

- Control ignition sources

-

- Conduct regular Dust Hazard Analysis (DHA)

What industries are at risk of dust explosions?

Industries like food processing, woodworking, metalworking, chemical manufacturing, and pharmaceuticals are particularly at risk.

Why is fugitive dust a problem?

Fugitive dust can accumulate unnoticed, increasing the risk of combustible dust explosions when disturbed.

Conclusion

The Washburn A Mill explosion reminds us how deadly combustible dust can be. But history doesn’t have to repeat itself. By understanding dust hazards, implementing dust hazard analysis (DHA), and prioritizing combustible dust training, businesses can prevent devastating explosions. Developers can also design safer upgrades for future mill developments.

Don’t wait for disaster to strike—take action today. Contact us to learn more about our combustible dust training and how we can help protect your workplace.