Published February 17, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A picture of Combustible Dust Training, Preventing Static Electricity Disasters, with Dust Safety Science

Combustible Dust Training and Preventing Static Electricity Disasters 🌍

Combustible Dust explosions pose a critical safety risk in various industries worldwide. Industries such as agriculture, food processing, mining, and metal manufacturing are particularly vulnerable to static electricity hazards due to the abundance of combustible materials and the lack of stringent safety measures. Past and present combustible dust explosions highlight the pressing need for comprehensive safety protocols and combustible dust training to mitigate risks effectively.

Worldwide manufacturing industries are affected by combustible dust explosions in all countries and continents, including North America, Europe, Asia, Africa, South America, Australia/Oceania, and Antarctica.

In this article, we will explore the importance of combustible dust training and preventing static electricity disasters, highlight the unique online combustible dust training courses of Dust Safety Science, and provide details on worldwide combustible dust training programs with Dust Safety Science.

One of the most effective methods for addressing combustible dust hazards is Dust Hazard Analysis, (DHA). A DHA is a proactive measure to identify potential risks and implement controls to prevent dust explosions. This article explores the importance of dust explosion safety in Latin America, provides an overview of DHA, and emphasizes the need for targeted training programs to enhance industrial safety. Beyond the tragic loss of life, dust explosions can cause extensive property damage, production downtime, and financial setbacks. Combustible dust, produced in manufacturing operations, can ignite under the right conditions, leading to explosions with catastrophic consequences.

Every year, combustible dust explosions and incidents happen across all manufacturing industries, causing widespread destruction, injuries, and even loss of life. The financial toll is staggering, with billions in property damage and legal costs. Despite the risks, many industrial facilities and manufacturing plants must tackle the challenges of combustible dust.

The question is: Are you doing enough to protect your business and employees from dust explosions? To create a safer workplace, visit worldwide combustible dust training programs with Dust Safety Science.

The Role of Static Electricity and Dust Explosions ⚡

Static electricity is a common ignition source in dust explosions. According to Wikipedia, Static electricity is an imbalance of electric charges within or on the surface of a material. The charge remains until it can move away by an electric current or electrical discharge. The word “static” is used to differentiate it from current electricity, where an electric charge flows through an electrical conductor. Static electricity accumulates when materials move or rub against each other, leading to an imbalance of electrical charges.

Mechanisms of Static Charge Generation

● Friction: Contact and separation between materials.

● Induction: Nearby charged objects influencing other materials.

● Conduction: Transfer of charge through direct contact.

According to Wikipedia, Static electricity is often generated through tribocharging, the separation of electric charges that occurs when two materials are brought into contact and then separated. Examples of tribocharging include walking on a rug, rubbing a plastic comb against dry hair, rubbing a balloon against a sweater, ascending from a fabric car seat, or removing some types of plastic packaging. In industrial settings with combustible dust, manufacturing operations like transporting, conveying, mixing, collecting, vibration, tumbling, blending, sorting, filling, emptying, pouring, funneling, dumping, loading, grinding, wrapping, and packaging, can generate static charges. In addition, transportation trucks, forklift equipment, pallet equipment, and other vehicles can also pose Electrostatic hazards. If not properly managed, these charges can discharge as sparks, igniting combustible dust clouds.

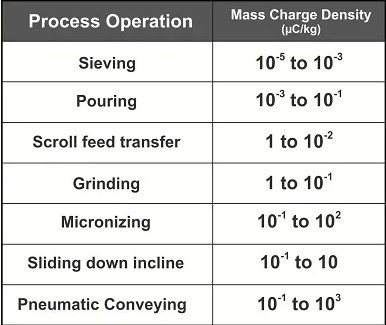

Image Credit: NFPA 77 / CLCTR: 50404, Charge generated on powders by different powder processing and handling operations

Types of Electrostatic Discharges

Electrostatic discharges, (ESD), can occur in various forms depending on the nature of charge accumulation and the materials involved. Each type presents unique risks in industrial environments, particularly in combustible dust atmospheres. Below are some of the most common electrostatic discharges:

- Brush discharge: A brush discharge occurs when a charged non-conductive surface releases its accumulated static charge to a nearby conductor or ground. This type of discharge has relatively low energy and typically does not ignite flammable gases. However, in combustible dust environments, a brush discharge can still pose an ignition risk, especially when the dust is finely dispersed and highly sensitive to ignition sources.

- Spark discharge: A spark discharge happens when two conductive objects with different electrical potentials come close enough to allow an electrical arc to form. The stored energy is released in a single, high-energy spark, which can easily ignite combustible dust clouds or flammable vapors. Spark discharges are particularly hazardous in industrial settings with inadequate grounding and bonding of equipment.

- Cone discharge: A cone discharge occurs inside or near bulk powder materials, particularly in hoppers, silos, or dust collection systems. As powder is transferred or agitated, electrostatic charges build up, leading to localized discharges in conical formations. These discharges have been known to ignite combustible dust clouds, making proper material handling and humidity control critical in preventing explosions.

Preventing Electric Static Induced Dust Explosions 🛡️

Many devices and materials used in electronics are particularly sensitive to static discharge. Conductive antistatic bags are commonly used to protect such components. People who work on circuits that contain these devices often ground themselves with a conductive antistatic strap. Electrostatic Discharge, ESD, is the sudden release of static electricity when two charged objects come into contact, essentially a “spark” or jolt of electricity transferring between them

In industrial settings such as paint or flour facilities, semiconductor facilities, pharmaceutical clean rooms, and hospitals, antistatic safety suits and boots, are sometimes used to prevent a buildup of static charge due to contact with the floor.

To mitigate the risks associated with static electricity and combustible dust, consider the following strategies:

- Bonding and Grounding: Connect conductive objects to prevent charge accumulation and facilitate the safe dissipation of static charges. This is a fundamental practice in controlling static electricity hazards. Examples include cables and clamps, wrist straps, and shoe grounding.

- Humidity Control: Maintaining appropriate and safe humidity levels can reduce static charge generation, as moisture increases the conductivity of materials, allowing charges to dissipate more readily.

- Use of Antistatic Materials: Incorporate environmental controls, materials, standing mats, containers, dust collector filters and bags, vacuums and vacuum equipment, hoses, piping, high reach lifts, moving equipment, and Personal Protection Equipment, PPE, designed to minimize or eliminate static charge buildup in equipment and protective clothing.

- Regular Maintenance and Housekeeping: Ensure that dust does not accumulate on surfaces, as layers of dust can insulate charges and create hazardous conditions.

- Electrostatic Discharge Protected Area, (EPA): The EPA can be a small workstation or a large manufacturing area. The main principle of an EPA is that there are no highly-charging materials in the vicinity of ESD sensitive electronics, all conductive and dissipative materials are grounded, workers are grounded, and charge build-up on ESD sensitive electronics is prevented. International standards are used to define a typical EPA and can be found for example from the International Electrotechnical Commission (IEC) or American National Standards Institute (ANSI).

- Static Locator: A Static Locator provides measurement of electrostatic charges.

- ElectroStatic Field Meters: Measurements of surface charge are obtained by electrostatic field meters.

- Employee Training: Educate workers on the dangers of static electricity and proper handling procedures to prevent ignition incidents.

5 Best Steps for Electrostatic Risk Assessment and Hazard Analysis

Effective electrostatic risk assessment and hazard analysis are essential for preventing ignition hazards in combustible dust environments. The following five steps provide a structured approach to identifying and mitigating electrostatic discharge risks:

1️⃣ Identify Electrostatic Hazards in the Workplace

Begin by assessing areas where static electricity may accumulate. Key factors to evaluate include:

- Material properties (conductivity, charge retention, and ignition sensitivity)

- Processes generating static charges (powder transfer, conveying, mixing, and filtration)

- Surfaces prone to charge buildup (plastic linings, insulated containers, rubber belts)

- Environmental conditions (humidity, temperature, and air movement)

2️⃣ Measure Charge Accumulation and Discharge Energy

Quantifying static charge buildup and potential discharge energy is crucial for understanding ignition risks. Methods include:

- Electrostatic charge measurement using field meters

- Surface resistivity testing to assess material conductivity

- Energy calculations to compare discharge potential against the minimum ignition energy (MIE) of combustible dusts

If discharge energy exceeds the MIE, immediate risk mitigation strategies should be implemented.

3️⃣ Assess Grounding, Bonding, and Insulation Effectiveness

Proper grounding and bonding are critical in controlling electrostatic charges. Evaluate:

- Bonding effectiveness between conductive components

- Grounding connections on machinery, containers, and personnel

- Insulation breakdown risks in pipes, hoses, and filters

- Use of conductive or antistatic materials in high-risk areas

Regular testing ensures that these systems function correctly to prevent static charge buildup.

4️⃣ Implement Risk Mitigation and Control Measures

Once hazards are identified, control measures should be applied to reduce electrostatic risks:

- Use proper grounding and bonding systems to dissipate static charges safely

- Control humidity levels (typically >50%) to minimize charge buildup

- Utilize antistatic or conductive materials for equipment and PPE

- Implement slow powder transfer rates to reduce electrostatic generation

- Install explosion protection systems where necessary (e.g., venting, suppression)

Mitigation strategies should align with industry standards such as NFPA 77, IEC 60079-32-1, and OSHA guidelines.

5️⃣ Monitor, Review, and Continuously Improve Safety Measures

Electrostatic risks can change due to process modifications, equipment wear, or environmental shifts. Establish a routine monitoring and review process:

- Conduct periodic electrostatic hazard assessments

- Train employees on static electricity safety and emergency response

- Perform regular equipment inspections and maintenance

- Update risk assessments when changes occur in material handling or processing

By continuously improving safety measures, facilities can ensure long-term protection against electrostatic ignition hazards.

How to Get Started with Combustible Dust and Dust Explosion Training

Whether your organization operates locally or globally, Dust Safety Science has the resources and expertise to help you enhance safety and compliance. Explore Custom Training Solutions or learn more about the Worldwide Training Program.

The Devastating Consequences of Dust Explosions 💥

Combustible dust incidents don’t just cause physical damage, they devastate lives. Workers face injuries or fatalities, businesses lose productivity, and the aftermath often leads to reputational damage and regulatory fines. To address this hidden threat, proactive safety measures are essential. Enter Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training a game changer in industrial safety.

The Need for Combustible Dust Training: Training on Standards and Codes Worldwide

Safety training empowers businesses to identify, control, and mitigate combustible dust hazards. A well-structured training program ensures compliance with standards, enhances workplace safety, and promotes operational efficiency. Dust Safety Science has successfully delivered training to industries worldwide, addressing diverse cultural, regulatory, and operational needs. Dust Safety Science’s Worldwide Combustible Dust Training Program is designed to ensure every client receives targeted and effective education.

To take the first step toward creating a safer workplace, visit Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training. The training solutions equip organizations to handle combustible dust risks effectively.

Understanding Combustible Dust Explosions 💥

What is Combustible Dust?

Combustible dust is made of fine particulate solids that can ignite and explode when dispersed in the air. These particles, ranging from wood shavings to powdered metals, form an explosive mix when conditions are optimum.

The Dust Explosion Pentagon identifies five critical elements required for a dust explosion:

- Fuel: Combustible dust.

- Oxygen: Present in the air.

- Ignition Source: Static electricity, heat, sparks, or flames.

- Dispersion: Particles suspended in air.

- Confinement: Enclosed spaces that amplify explosive force.

When all five elements converge, the results can be catastrophic.

Common Causes of Dust Explosions Worldwide

- Overheated Bearings: Inadequately maintained equipment is a frequent ignition source.

- Electrical Failures: Faulty wiring, static electricity, or faulty equipment can lead to sparks, including Walkie Talkies, Cell phones, and Microphones.

- Dust Accumulation: Poor housekeeping allows dust to collect and become a serious hazard.

- Smoking: Cigarettes, Cigars, Lighters, Matches.

- Mechanical Malfunctions: Equipment failures can generate heat and friction, igniting dust clouds.

Industries at Risk of Combustible Dust Explosions 🏭

While combustible dust hazards exist in many industries, some industries are more prone to combustible dust explosions than others:

- Food Processing: Soybean, flour, coffee, rice, cotton, beans, cacao, wheat, cocoa, sugar, corn, maize, nuts, and grain dust.

- Woodworking: Sawdust and fine wood particles.

- Pharmaceuticals: Fine powders, plastics, and chemicals.

- Biomass: Wood, wood residues, tobacco, energy crops, agricultural residues. including straw, peat, and organic waste from industry and households.

- Coal: Coal Mines, coal dust, and Coking coal dust.

- Fireworks: Metallic fine dust such as Aluminum, magnesium, titanium, zinc, iron filings, strontium and barium salts

- Metalworking: Aluminum, magnesium, zirconium, and other metallic dust.

Each industry requires customized training to manage unique risks. Learn how tailored training can address these challenges by visiting Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Historical Dust Explosion Prevalence Worldwide

Dust explosions are not limited to any single region or industry, emphasizing the need for targeted prevention. The potential for incidents exists, especially in agriculture and manufacturing sectors where dust is prevalent. Ongoing research and improved safety standards remain vital to preventing tragedies associated with combustible dust in the region.

Notable Case Studies with Static Electricity Present:

- According to a research paper, “Taming the Beast – Lessons Learned from 5 Decades of Aluminium Dust Explosions,” SYMPOSIUM SERIES NO 167 HAZARDS 30 © 2020 IChemE, in 1983 when AMG Alpoco (then the Aluminium Powder Company Ltd), had an explosion on a melt atomisation line which caused significant damage to the process. This was 1 of 6 incidents at the same manufacturing facility. Consultation with an electrostatic expert at the time deemed static electricity cause unlikely, although not impossible.

- According to an article at the 13th International Conference on Electrostatics, IOP Publishing, Journal of Physics: Conference Series 301, “Statistical analysis of fires and explosions attributed to static electricity over the last 50 years in Japanese industry,” Author: A Ohsawa 2011 J. Phys.: Conf. Ser. 301 012033 doi:10.1088/1742-6596/301/1/012033: A statistical analysis of 153 accidents attributable to static electricity in Japanese industry over the last 50 years. A more thorough understanding of their causes could help prevent similar incidents and identify hazards that could assist in the task of risk assessment. Most of the incidents occurred during operations performed by workers. In addition, more than 70% of the flammable atmospheres resulted from the presence of vapours. A noteworthy finding is that at least 70% of the ignitions were caused by isolated conductors including operators’ bodies leading to spark discharges, which could have easily been prevented with earthing.

- On July 7, 2021, the national news agency, Focus Taiwan, reported an explosion and fire at a plastic products plant in Kaohsiung City, Taiwan. While the silo is filling, pellets are falling down, but the dust remains suspended in the air for a while. The pellets all down this cone accumulate electrostatic charge because of the friction and generate electrostatic discharges toward the silo walls, a phenomenon known as cone discharge. During the filling of a silo made of concrete or metal, you can see the flashes of the cone discharges, especially at night. A question was raised on how the issue could have been electrostatic discharge if all of the silos are grounded. According to Eyal Zadok, this doesn’t matter- the charge is still being built up along the cone and in the materials.

- OSHA has issued numerous citations for using standard Shop Style vacuum cleaners where Class II Div 2 equipment is required. NFPA 654, 8.2.3.1 standard clearly states that Vacuum cleaners shall be listed for use in Class II hazardous locations. Static electricity build-up on individual dust particles and the plastic hoses and attachments are serious issues, including possible dust cloud formation. In addition, the shop vac style motors are not rated nor classified as explosion proof.On February 25, 2021, Channel News Asia reported a dust explosion and fire at an industrial building in Tuas, Singapore. Secondary flash fires also occurred which were likely due to the combustion of potato starch powders which were allowed to accumulate at the worksite.

Combustible dust incidents continue to occur worldwide and in many industries, as presented in this combustible dust research and incident database from Dust Safety Science.

Why Combustible Dust Safety Training is Crucial

Industrial sectors are rapidly evolving, and many countries are expanding their manufacturing capabilities. With industries such as agriculture (grain storage), sugar refining, and mining becoming more prominent, combustible dust hazards are increasing. Without adequate training on combustible dust standards and codes, businesses risk exposure to workplace explosions, environmental damage, and legal consequences.

Key Reasons Why Training is Essential:

- Prevention of Dust Explosions: Combustible dust explosions can cause fatalities, severe injuries, and widespread damage. Proper training helps mitigate the risk of explosions.

- Compliance with Regulatory Requirements: Many countries in South America are enhancing their safety standards, and training ensures businesses meet these evolving requirements.

- Improved Workplace Safety: Employees trained in the hazards of combustible dust are better prepared to recognize risks and implement effective safety measures.

- Reduction in Liability and Operational Costs: Organizations can avoid costly accidents, fines, and downtime by complying with safety regulations and maintaining safe working environments.

Regulatory Compliance for Electrostatic Atmospheres

Compliance with electrostatic safety regulations is essential for preventing ignition hazards in combustible dust environments. Key standards, such as NFPA 77 (Recommended Practice on Static Electricity) and IEC 60079-32-1 (Electrostatic Hazards in Explosive Atmospheres), provide guidelines for grounding, bonding, and charge dissipation in industrial settings. Adhering to these regulations helps facilities mitigate electrostatic risks, ensuring workplace safety and compliance with OSHA, NFPA, IEC, and ATEX directives. Some examples of regulatory compliance include:

- IEC Technical Specification 60079-32-1 Consolidated version: IEC TS 60079-32-1:2013+AMD1:2017 CSV : https://webstore.iec.ch/en/publication/60166 IEC TS 60079-32-1:2013+A1:2017 gives guidance about the equipment, product and process properties necessary to avoid ignition and electrostatic shock hazards arising from static electricity as well as the operational requirements needed to ensure safe use of the equipment, product or process. It can be used in a risk assessment of electrostatic hazards or for the preparation of product family or dedicated product standards for electrical or non-electrical machines or equipment. The purpose of this document is to provide standard recommendations for the control of static electricity, such as earthing of conductors, reduction of charging and restriction of chargeable areas of insulators. In some cases static electricity plays an integral part of a process, e.g. electrostatic coating, but often it is an unwelcome side effect and it is with the latter that this guidance is concerned.

- ISO/IEC 80079-20-2:2016: Explosive atmospheres, Part 20-2: Material characteristics — Combustible dusts test methods: https://www.iso.org/standard/66564.html ISO/IEC 80079-20-2:2016 is published as a dual logo standard and describes the test methods for the identification of combustible dust and combustible dust layers in order to permit classification of areas where such materials exist for the purpose of the proper selection and installation of electrical and mechanical equipment for use in the presence of combustible dust.

- IEC 60079-0:2017: https://webstore.iec.ch/en/publication/32878 IEC 60079-0:2017 specifies the general requirements for construction, testing, and marking of Ex Equipment and Ex Components intended for use in explosive atmospheres.

- IEC 60079-32-1 (13.4.1) and NFPA 77 (7.4.1.6) & (7.4.1.4) regarding grounding state: “Temporary connections can be made using bolts, pressure-type earth (ground) clamps, or other special clamps. Pressure-type clamps should have sufficient pressure to penetrate any protective coating, rust, or spilled material to ensure contact with the base metal with an interface resistance of less than 10 Ω.”

- European Committee for Standardization / European Committee for Electrotechnical Standardization: CEN /CENELEC (2019) EN 1127-1 Explosive atmospheres

- UL Solutions: Non-electrical equipment can potentially present a risk of explosion due to impact, friction, hot surfaces, and static electricity, among other methods. Such equipment installed in a potentially explosive atmosphere shall be designed to prevent these risks from occurring and causing an explosion.

- According to Wikipedia, the ATEX directives are two of the EU directives describing the minimum safety requirements for workplaces and equipment used in explosive atmospheres. The ATEX name is an initialization of the term ATmosphères EXplosibles, (French for “explosive atmospheres”).

ATEX is the name commonly given to the 2 European Directives for controlling explosive atmospheres:

- Directive 99/92/EC (also known as ‘ATEX 137’ or the ‘ATEX Workplace Directive’): This covers the minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres. The text of the Directive and the supporting EU produced guidelines are available on the EU-website.

The Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) implement the requirements of this Directive in Great Britain (England, Scotland and Wales). Further information can be found in the section on explosive atmospheres in the workplace. - Directive 2014/34/EU (also known as ‘ATEX 114’ or ‘the ATEX Equipment Directive’): This covers the approximation of the laws of Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres. The text of the Directive and EU produced supporting guidelines are available on the EU website.

The Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations 2016 (the 2016 EPS regulations) implement the requirements of this Directive in Great Britain. More information can be found in the section on equipment and protective systems intended for use in explosive atmospheres. - NFPA 77 Recommended Practice on Static Electricity: This recommended practice offers guidance on identifying, evaluating, and controlling static electric hazards for purposes of preventing fires and explosions.

Regulatory agencies like OSHA and standards like NFPA 77 mandate measures to control combustible dust risks. Failure to comply not only endangers lives but also leads to penalties. Training helps organizations stay compliant and avoid legal consequences.

Risk Mitigation

Identifying and mitigating dust hazards is central to a safe work environment. Training programs, such as those offered by Dust Safety Science, provide actionable insights to reduce risks through Dust Hazard Analyses (DHA) and preventive strategies.

Employee Safety

Education is key to empowering workers. Through training, employees learn to:

- Recognize Combustible Dust Hazards.

- Use properly rated, Combustible Dust Control Equipment, such as Dust Collectors, Dust Control Fans, and Combustible Dust rated Vacuums.

- Use personal protective equipment (PPE) effectively.

- Follow emergency procedures during incidents.

Operational Efficiency

Preventing explosions reduces downtime, maintains productivity, and saves costs associated with accidents. Proper training ensures smoother operations and a safer workplace.

Benefits of Combustible Dust Standards and Codes Training

Investing in specialized training on combustible dust standards and codes brings many benefits, from improving safety and compliance to enhancing overall operational efficiency. Key benefits include:

- Enhanced Safety Culture: Training fosters a safety-conscious work environment and reduces the likelihood of accidents.

- Meeting International and National Standards: Employees become well-versed in global and local combustible dust standards, ensuring compliance with regulatory codes.

- Risk Mitigation: Trained professionals can identify potential hazards early, preventing costly incidents and improving operational continuity.

- Continuous Improvement: Regular training ensures that employees are aware of new codes, emerging risks, and technological advancements in dust management.

Overview of the 2025 Combustible Dust Standards and Codes Training

The 2025 Dust Safety Science Combustible Dust Training Program is a key initiative designed to address the growing need for dust safety expertise worldwide. This program provides comprehensive training on combustible dust standards, regulations, and codes specific to the region’s diverse industries.

Training Highlights:

- Expert-Led Sessions: Learn from global experts in combustible dust safety and explosion prevention.

- Localized Content: The program is tailored to meet the unique needs of industries, including agriculture, mining, manufacturing, and more.

- Practical Training: Hands-on exercises and real-world case studies provide participants with the tools they need to assess and address combustible dust hazards.

Who Should Attend?

- Safety Managers

- Plant Engineers

- Industrial Hygienists

- Maintenance Supervisors

- Environmental Health and Safety (EHS) Managers

- EHS, CIH, Process Safety, Engineering, and Fire Science students

- Manufacturing and Factory Personnel

Learn more about the training program: Dust Safety Science Combustible Dust Training Program

Core Elements of Combustible Dust Safety Training

Dust Hazard Analysis (DHA)

A Dust Hazard Analysis, DHA, is the cornerstone of dust safety. A Dust Hazard Analysis involves identifying hazardous zones, evaluating risk severity, and implementing control measures. Training ensures participants can conduct effective DHAs for their facilities.

Housekeeping and Maintenance

Dust accumulation poses a significant risk. Training covers:

- Effective cleaning techniques to minimize airborne dust.

- Preventive maintenance schedules for equipment.

- Targeting hard-to-clean areas where dust tends to settle.

Ventilation and Dust Collection

Proper ventilation and dust collection are critical to control dust at its source. Training addresses:

- Designing effective dust collection systems.

- Ensuring ongoing system inspections and maintenance.

- Educating staff on the proper use of dust collection equipment.

Ignition Source Control

Ignition sources are often preventable. Training programs focus on:

- Identifying ignition risks, such as open flames, hot surfaces, and electrical faults.

- Implementing spark detection and suppression systems.

- Using explosion-proof equipment in high-risk areas.

Emergency Response Planning

When an incident occurs, preparedness can save lives. Training equips workers with:

- Evacuation procedures and drills.

- Fire suppression strategies.

- First aid skills to handle injuries effectively.

Invest in these essential safety components by enrolling in the Dust Safety Science Combustible Dust Training Program

Why Choose Dust Safety Science for Dust Explosion Training?

Comprehensive Curriculum

The Combustible Dust Explosion training program delves deep into combustible dust safety, from understanding explosion mechanics to fundamentals of dust fire and explosion safety and dust hazard analysis. Learn more at Dust Safety Science Combustible Dust Training Program.

Expert Instructors

With a team of seasoned professionals, Dust Safety Science brings unparalleled expertise. Their instructors ensure participants receive actionable, industry-specific guidance.

Flexible Training Options

Choose a format that fits your needs:

- Online Courses: Flexible and accessible.

- In-Person Training: Hands-on experience for practical learning.

- Hybrid Options: A blend of convenience and interactivity

- English, Portuguese, and Spanish subtitles are available

Customized Training Solutions

Every industry faces unique challenges. Dust Safety Science offers tailored training solutions, that address specific risks and compliance needs. Start customizing your training today by visiting Dust Safety Science’s Training Page.

Certificate of Completion

- Certificate of Completion provided after successful completion of a course 🏆

Take Action: Ensure Your Facility’s Safety Today

Combustible dust standards and codes training are essential for ensuring workplace safety in growing industrial sectors. As regulations evolve and industries expand, businesses must stay ahead of safety requirements to prevent dust explosions, protect workers, and minimize operational risks.

Programs like the 2025 Dust Safety Science Combustible Dust Training Program offer industry-specific, expert-led training to address combustible dust hazards. By leveraging the training, resources, and safety guidelines provided by governmental bodies worldwide, industries can reduce accidents, enhance compliance, and safeguard their workforce.

Don’t wait until it’s too late and register for the 2025 Combustible Dust Standards and Codes Training, visit the: Dust Safety Science Combustible Dust Training Program

A picture of a Sample Certificate of Completion for Combustible Dust and Dust Explosion Course

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science provides additional Combustible Dust Incidents and Static Electricity with a Podcast. Click on these Podcast Links: Analyzing Electrostatic Ignition Likelihood After An Explosion Incident Part 1 and Analyzing Electrostatic Ignition Likelihood After An Explosion Incident Part 2

A picture of Dr. Chris Cloney, an Expert on Combustible Dust Hazard Analysis

Resources:

Visit: Dust Safety Science’s Training Page

Visit: Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Visit: Combustible Dust Standards and Codes Training

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit: Dust Safety Science (Global Incident Tracking)

Visit: Dust Safety Academy (Resources, Training, and Events)

Visit: Dust Safety Professionals (Need Help? Get Support Today!)

Visit: Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.