Published November 18, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What Is Nitrogen?

Nitrogen is a chemical element represented by the symbol N and has an atomic number of 7. It is a colorless, odorless, and tasteless gas that makes up approximately 78% of the Earth’s atmosphere. This makes nitrogen the most abundant gas in the air we breathe.

Industrially, nitrogen is used in several ways:

- Food packaging: Nitrogen is used to displace oxygen in food packaging, extending shelf life by preventing oxidation and spoilage.

- Chemical production: Nitrogen serves as a feedstock in the production of fertilizers and various chemicals.

- Manufacturing: It’s used in the creation of metals, electronics, and pharmaceuticals by providing an inert atmosphere that minimizes reactions with oxygen.

- Inerting Systems: introduce inert gases, such as nitrogen, to reduce the oxygen content in enclosed spaces, making it difficult for dust explosions to occur. This is a proactive measure to prevent explosions from taking place in the first instance.

While nitrogen is a vital resource for numerous applications, it is essential to understand its safety implications in these environments.

Understanding Nitrogen’s Role in Industry

Nitrogen, a ubiquitous element in Earth’s atmosphere, plays a significant role across various industries, ranging from food packaging to chemical production. While it’s essential for many processes, there’s often confusion about its safety properties, particularly its flammability. The question “Is nitrogen flammable?” is common, especially in industries where safety and risk management are crucial.

Understanding nitrogen’s behavior and safety characteristics is essential to avoiding accidents and ensuring smooth operations. This article will explore nitrogen’s properties, its role in fire and explosion prevention, and the safety precautions needed when working with this gas.

Nitrogen’s Chemical Properties

Nitrogen is chemically inert under normal conditions. This means that it does not easily react with other substances. Unlike reactive gases such as oxygen or hydrogen, nitrogen does not support combustion and does not readily form compounds unless under specific conditions (such as high pressure or temperature).

At room temperature, nitrogen molecules (N₂) are stable, and their properties allow them to act as an inert gas, which is crucial in many industrial settings. This inert nature is the reason nitrogen is commonly used in environments where reactions with oxygen could be dangerous, such as in fire suppression systems or when handling combustible dust.

Because of its stable nature, nitrogen is classified as non-flammable and can play a role in preventing combustion by displacing oxygen in confined spaces or controlled environments.

Is Nitrogen Flammable?

The simple answer to the question “Is nitrogen flammable?” is No. Nitrogen is a non-flammable, nor explosive, inert gas that does not ignite or support combustion under normal conditions. However, there are common misconceptions about nitrogen and flammability, often arising from confusion with other gases.

For instance, gases like hydrogen, acetylene, or propane are flammable and can easily catch fire, while nitrogen does not have this property. Some might confuse the role of nitrogen in displacing oxygen, leading to concerns that nitrogen could contribute to fire or explosion. While nitrogen doesn’t catch fire, it can contribute indirectly to safety hazards when it displaces oxygen in confined spaces.

The Role of Nitrogen in Fire and Dust Explosion Prevention

Nitrogen plays a critical role in preventing fires and explosions in several industrial settings. One of the key uses of nitrogen is its ability to inert environments by reducing the concentration of oxygen to levels that are too low to support combustion.

In combustible dust management, for example, nitrogen is used to fill spaces where combustible dust could form and ignite. By creating an oxygen-deprived atmosphere, nitrogen helps eliminate the risk of explosions in environments like grain silos, chemical plants, and oil refineries.

Real-world applications include:

- Fire suppression systems: Nitrogen is used in automated fire suppression systems that protect sensitive equipment in places like server rooms and chemical processing facilities.

- Industrial manufacturing: In environments where combustible chemicals are used, nitrogen helps prevent accidental ignition by creating a non-reactive atmosphere.

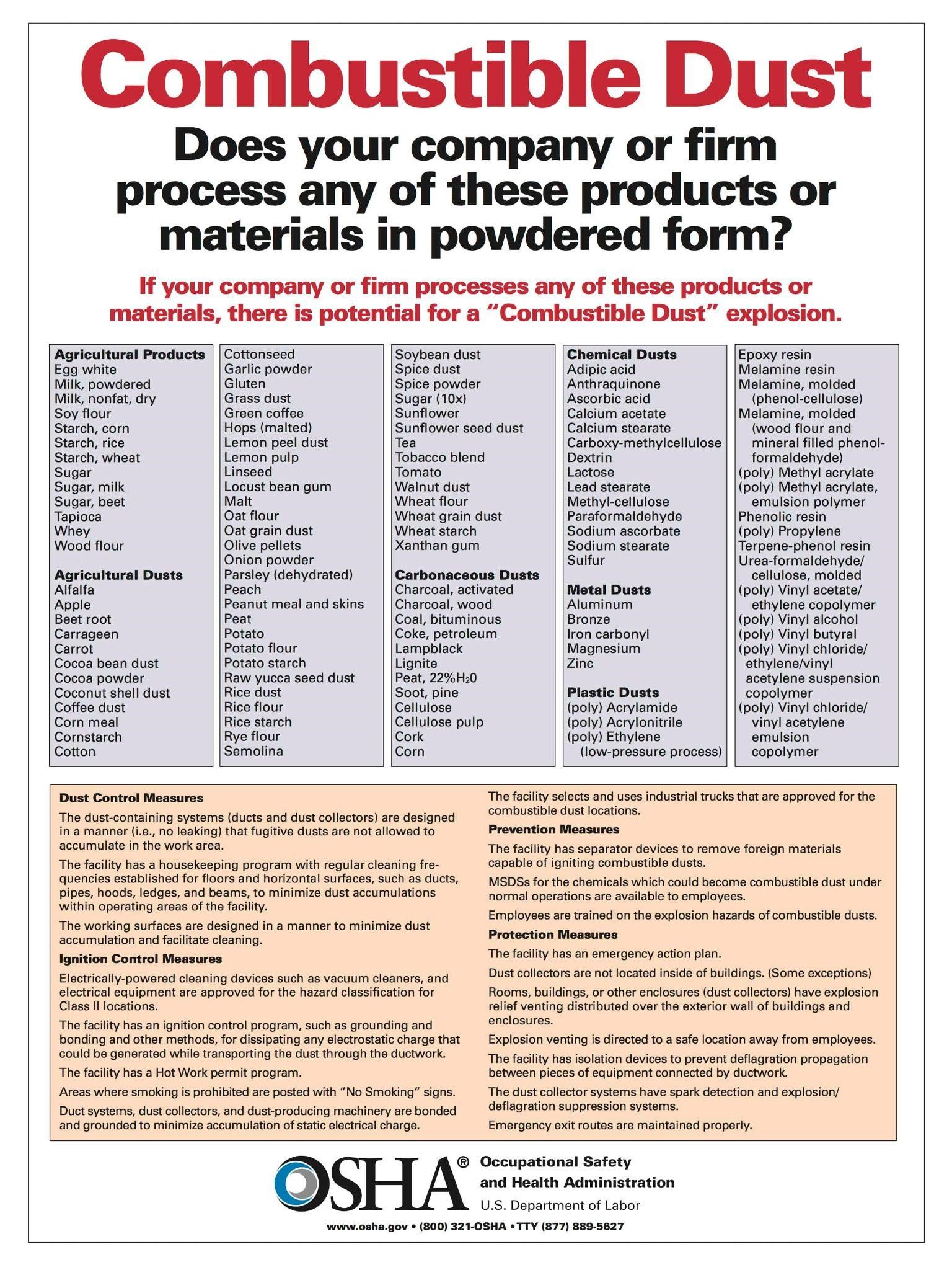

Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing.

Combustible dust may seem like an innocuous byproduct of industrial processes, but in certain conditions, it can pose severe risks, including dust explosions and fires. Understanding the formation, identification, and risks associated with combustible dust clouds is crucial for safety management in industries such as manufacturing, woodworking, and metalworking.

A combustible dust cloud consists of fine particles suspended in the air, when exposed to an ignition source, can lead to a fire or explosion. Combustible dust is created from various materials, including organic substances like wood, grain, metals, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area.

Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as cutting, grinding, or transporting materials. These clouds can accumulate in hidden areas such as rafters, ductwork, or equipment, leading to dust explosions.

Nitrogen in Different Forms: Liquid Nitrogen and Gaseous Nitrogen Safety

While nitrogen is most commonly used in its gaseous form, it can also exist as liquid nitrogen under extreme conditions. Liquid nitrogen is nitrogen that has been cooled to below its boiling point of -196°C (-321°F), making it incredibly cold and capable of freezing almost anything it comes into contact with.

Gaseous Nitrogen vs. Liquid Nitrogen:

- Gaseous nitrogen is used in applications such as purging tanks, controlling atmospheres, and inerting spaces.

- Liquid nitrogen is often used in cryogenics, medical procedures, and industrial cooling.

Safety Considerations:

- Liquid nitrogen is non-flammable, but its extremely low temperature poses safety hazards. Direct contact can cause severe frostbite or cold burns.

- Gaseous nitrogen can displace oxygen in confined spaces, leading to an asphyxiation hazard, but it is not dangerous in open areas where air circulation is adequate.

Health and Safety Risks Related to Nitrogen Use

While nitrogen is not flammable, it does pose some health and safety risks, particularly when used in confined spaces. Because nitrogen is inert, it does not support life, and when used in poorly ventilated areas, it can displace oxygen, leading to asphyxiation.

Symptoms of Nitrogen-related Asphyxiation:

- Dizziness

- Unconsciousness

- Shortness of breath

- Confusion

- Loss of coordination

Best Practices:

- Ventilation: Always ensure proper ventilation in areas where nitrogen is being used to avoid oxygen displacement.

- Gas detection: Use oxygen sensors in confined spaces to monitor oxygen levels and alert workers to any dangerous conditions.

- Training: Workers should be trained to recognize the risks associated with nitrogen and the symptoms of asphyxiation.

Safety Guidelines for Working with Nitrogen

To ensure safe handling of nitrogen, it is essential to follow established guidelines:

Storage and Handling:

- Cylinders: Store nitrogen cylinders in a well-ventilated area, away from heat sources.

- Proper labeling: Clearly label cylinders to indicate the contents and ensure they are handled by trained personnel.

OSHA standard 1910.101 requires compressed gases:

- In a safe condition to the extent that this can be determined by visual inspection

- Handled, stored, and utilized safely

- Shall have pressure relief devices installed and maintained

PPE for Liquid Nitrogen:

- Face shields, gloves, and protective clothing are recommended when handling liquid nitrogen to protect against burns and frostbite.

- Ensure that employees understand the proper procedures for handling and using nitrogen to avoid injury or accidents.

Case Studies: Nitrogen in Industrial Safety Applications

Several industries rely on nitrogen to improve safety and prevent dangerous incidents:

Case Study 1: Oil Refineries:

In oil refineries, nitrogen is used to inert process vessels and pipelines, preventing explosions caused by flammable gases. By using nitrogen to displace oxygen, refineries have successfully reduced the risk of catastrophic fires or explosions in high-risk areas.

Case Study 2: Chemical Plants:

Chemical plants often use nitrogen to protect reactors and storage tanks from dangerous reactions. By creating an inert atmosphere, nitrogen ensures that volatile chemicals do not come into contact with oxygen, which could trigger combustion.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), and the Internet of Things, (IoT), in Managing Nitrogen Hazards

The integration of Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) has revolutionized safety management for nitrogen hazards, particularly in industrial applications where nitrogen is used as a compressed gas. Advanced AI algorithms analyze vast datasets from IoT-connected sensors, providing real-time monitoring of nitrogen storage tanks, pipelines, and confined spaces. These sensors detect critical parameters such as pressure, temperature, and oxygen levels, enabling AI to identify potential risks like leaks or oxygen displacement before they escalate into emergencies. By continuously learning from historical data, ML models predict failure patterns and suggest proactive maintenance, reducing the likelihood of equipment malfunction and workplace accidents.

Furthermore, these technologies enable automated safety interventions, such as triggering ventilation systems or shutting off nitrogen supply valves during abnormal conditions. IoT devices integrated with AI-driven platforms also enhance worker safety by sending real time alerts to personnel when hazardous conditions are detected. For example, wearable devices equipped with IoT sensors can monitor oxygen levels in confined spaces, ensuring workers are warned of asphyxiation risks in real time. This synergy of AI, ML, and IoT has not only improved the accuracy and speed of nitrogen hazard detection but also enhanced operational efficiency and compliance with safety regulations.

FAQs About Nitrogen and Flammability

Can nitrogen cause an explosion?

No, nitrogen cannot cause an explosion on its own, as it is a non-flammable gas. However, it can displace oxygen in confined spaces, leading to asphyxiation hazards.

Is nitrogen flammable when mixed with other gases?

No, nitrogen itself is non-flammable, and it does not support combustion. However, when mixed with flammable gases like hydrogen or methane, the flammable gas may still pose a risk.

How can nitrogen be dangerous if it’s not flammable?

Nitrogen can be dangerous due to its ability to displace oxygen in confined spaces, leading to the risk of asphyxiation. Proper ventilation and gas detection are crucial to avoid this hazard.

Conclusion

In summary, nitrogen is not flammable and plays an essential role in industrial safety by preventing fires and explosions. It’s widely used in fire suppression systems, inerting environments, and managing combustible dust hazards. While nitrogen is safe when handled correctly, it’s crucial to understand its risks, particularly in confined spaces where it can displace oxygen and cause asphyxiation.

By following safety protocols and using nitrogen in a controlled manner, industries can harness its benefits while keeping workers safe. Always ensure proper ventilation, use gas detectors, and follow recommended protective measures when handling nitrogen.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on the Differences in Incident Investigation for Dust Explosions Compared to Gas Explosions, with a Podcast. Click on the latest Podcast Link: Differences in Incident Investigation for Dust Explosions Compared to Gas Explosions

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.