Update September 9, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Certain bulk materials and solid organic materials and products, such as paper, wood, flour, metal, coal, plastic, cotton, textile fibres, and rubber that may combust in powdered form, are extensive and include a wide range of materials. These materials are used in a wide range of industries and processes, such as agriculture, woodworking facilities, chemical manufacturing, pharmaceutical production, furniture, textiles, fossil fuel power generation, recycling operations, and metal working. Some materials, such as Zinc or Potatoes, are not combustible in larger pieces. However, these materials can be combustible when pulverized to fine dust, and as a smaller particle size, become an explosion hazard when suspended in air, catch fire near hot surfaces, or an ignition source such as static electricity, and cause combustible dust explosions. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials. Stating the possibility of a combustible dust hazard is now a requirement on the Safety Data Sheet, (SDS), under WHMIS 2015.

The National Fire Protection Association, NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, provides guidance on combustible dust suppression and control. The NFPA 654 Standard is referenced by OSHA’s Combustible Dust National Emphasis Program (NEP) to identify dust hazards and define mitigation strategies, such as deflagration venting and suppression, that help protect life and property. The NFPA standards provide industry-recognized safety practices for facility and systems design, process equipment protection, fugitive particle control and housekeeping, ignition source identification and control, fire protection, training and procedures, inspection, and maintenance.

The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dusts and dust particles as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air, as dust clouds, or some other oxidizing medium over a range of concentrations. Understanding these characteristics is vital for identifying combustible dust hazards, managing the risks associated with combustible dusts, ensuring workplace safety and compliance, and preventing a combustible dust explosion. On its website, OSHA maintains a comprehensive list of combustible materials.

In addition, confinement is the final element making up the dust explosion pentagon. It is important to note that complete confinement (e.g., four walls, floor, and a roof, see textbook of Amyotte) is not necessary for combustible dust explosions to reach destructive pressures. Any confinement or confined space can lead to pressure rise, acceleration of the flame, or pressure piling, which can all increase the explosion violence.

Evaluating the Combustibility of Dust

Determining the combustibility of dust present or determining whether the dust is combustible in your facility requires professional evaluation through laboratory testing. This process involves igniting a sample of the particles in a controlled environment, creating a simulated explosive atmosphere with flash fires in the air, and analyzing key parameters, such as the Minimum explosible concentration (MEC) of dust in the air, and assessing the potential hazards and explosion risks.

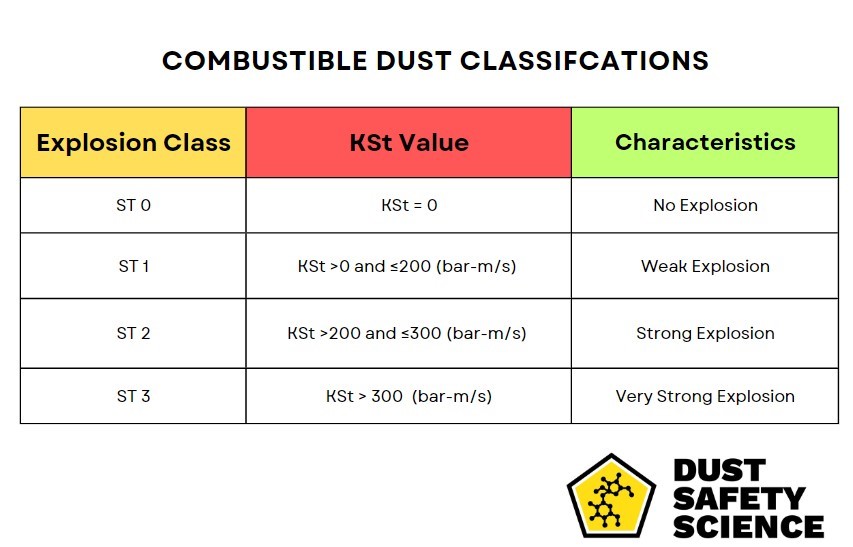

Two critical elements of this analysis are the Kst value and the Pmax value. The Kst value measures the severity of an explosion that could occur if the particles ignites, as suspended dust will create dust clouds, taking into account factors such as the dust particle size, shape, and moisture content. Meanwhile, the Pmax value indicates the maximum pressure generated by a potential explosion.

The Dust Explosion Classes

Combustible dusts are divided into four classes: St 0, St 1, St 2, and St 3. A high Kst value will rank highly on the class scale, indicating a potential explosion. Similarly, a Kst value of 0 means there is zero risk of a combustible dust explosion.

St 0: Kst value 0 – no explosion. Typical of silica dust, welding-generated dust, and thermally generated dust (from cutting processes, for example).

St 1: Kst value >0-200 – weak explosion. Typical of charcoal, powdered milk, sugar, sulfur, wood dust, and zinc.

St 2: Kst value >200-300 – strong explosion. Typical of cellulose, wood flour, poly methyl acrylate (PMA).

St 3: Kst value >300 – very strong explosion. Typical of metal dusts such as aluminum, magnesium, and titanium.

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible Dust Suppression, visit this podcast episode: Dust Explosion And Combustion Test Methods With Dr. Ashok Dastidar.

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.