Published December 10, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A picture of Combustible Aluminum Dust, a Dust Cloud, and a Dust Explosion in a Metal Processing Facility

A picture of Combustible Aluminum Dust, a Dust Cloud, and a Dust Explosion in a Metal Processing Facility

What are Metal Materials and Flammable Materials?

When most people think of flammable materials, they picture wood, paper, or gasoline—not metal. “Is metal flammable?” might seem straightforward, but the truth is far more scientific. Understanding metal combustibility is critical in manufacturing, construction, and storage, where metals are widely used in various forms. Misjudging the flammability of metals can result in catastrophic consequences, including fires and explosions.

This article explores the science behind metal flammability, factors influencing combustibility, and safety practices for handling potentially flammable metals.

Metal is Flammable and is an Explosion Hazard

Yes, many metals are flammable. According to Wikipedia, metal fires represent a unique hazard because people are often not aware of the characteristics of these fires and are not properly prepared to fight them. When a fire or incident occurs, a person may not know what type of metal is burning. Therefore, even a small metal fire can spread and become a larger fire in the surrounding ordinary combustible materials. Certain metals catch fire in contact with air or water, a substance is pyrophoric, (for example, sodium an alkali metal), which exacerbates this risk. Plutonium, magnesium, and titanium are dangerous in powdered form, as they can catch fire spontaneously if they are damp by moisture. Zirconium fires are challenging to extinguish, as they react with water to release hydrogen gas, increasing the hazardous incident. A person can ignite iron filings or wire wool with a match. Practical applications include the sparking mechanisms in lighters and various toys, using ferrocerium; starting fires without matches, using a firesteel; the flintlock mechanism in firearms; and spark testing ferrous metals.

Bulk materials of combustible metals do not usually have immediate fire risks because heat is conducted away from hot spots so efficiently that the heat of combustion cannot be maintained. Significant heat energy is required to ignite a contiguous mass of combustible metal. Generally, metal fires are a hazard when the metal is in the form of sawdust, machine shavings, or other metal “fines”, which combust more rapidly than larger blocks due to their increased surface-area-to-volume ratio. Metal fires can be ignited by the same ignition sources that would start other common fires.

What is Flammability and Combustibility?

Flammability refers to a material’s ability to ignite and sustain combustion. Common flammable substances, like wood and fabric, have relatively low ignition temperatures and readily support a flame.

Combustibility is a broader term that describes a material’s ability to burn under certain conditions, even if it is not easily ignited. A material may be combustible but not classified as flammable if it requires high temperatures or specific conditions to ignite.

Key Terms in Combustion Science

- Ignition Temperature: The minimum temperature at which a material spontaneously ignites.

- Flash Point: The lowest temperature at which a material emits enough vapor to ignite.

- Combustive Reactions: Chemical processes that release heat and light in the presence of oxygen.

Metals differ from common materials in their combustive behavior, requiring closer scrutiny of particle size, surface area, and environmental conditions.

Key Points About Metal Flammability:

- Dust Clouds: Metal dust forms combustible dust clouds that can ignite and lead to explosions if the right air-to-fuel ratio exists. An example is throwing bulk organic material into the air, which forms a dust cloud.

- Ignition Temperature: The temperature required to ignite metal dust can be relatively low, making it a potential hazard in industrial and processing environments.

- Static Electricity: Metal dust can burn or explode with an ignition source, such as an open flame, spark, hot surface, electrical equipment, smoking, or static electricity.

- Confined Spaces: Dust explosions are more dangerous when metal dust, accumulates in confined spaces, as the pressure can lead to secondary explosions.

Types of Metals and Their Combustion Potential

Ferrous Metals

Ferrous metals, such as iron and steel, are generally less combustible due to their high melting points and low reactivity. However, under specific conditions, such as in finely divided powder form, even ferrous metals can ignite.

Non-Ferrous Metals

Non-ferrous metals, including aluminum, magnesium, and titanium, are more prone to combustion. These metals burn more readily in fine particle form due to increased surface area and high oxidation potential. For instance:

- Magnesium burns with an intense white flame and poses challenges in fire suppression.

- Aluminum dust can lead to devastating explosions in industrial settings.

Factors Influencing Combustibility

- Particle Size and Shape: Smaller particles ignite more easily due to increased surface area.

- Environment: Oxygen levels, humidity, and temperature can amplify combustion risks.

Metal as a Combustible Dust

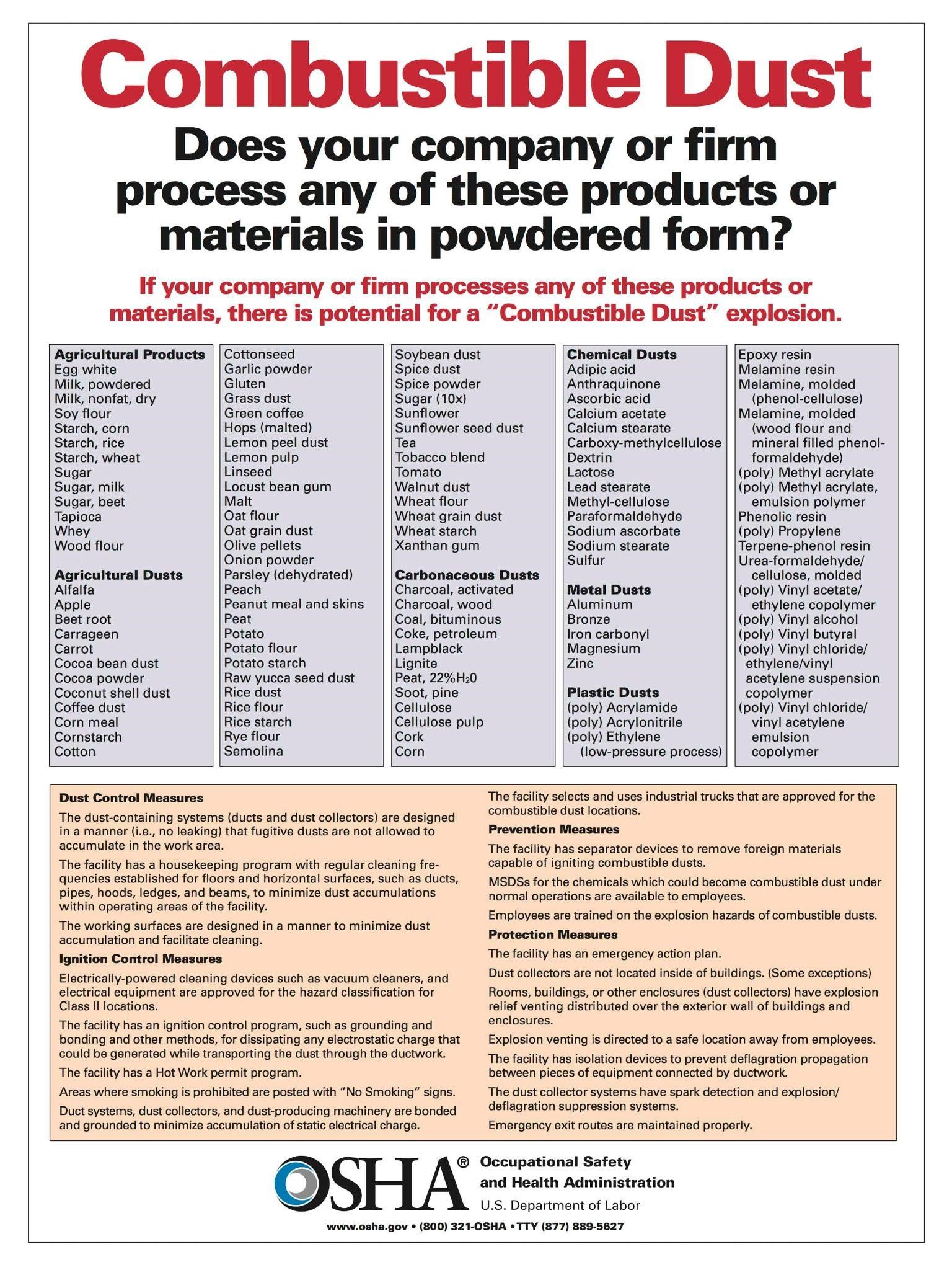

Metal dust is considered combustible dust, and other combustible materials and products, such as paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are not combustible in larger bulk material pieces but can be when pulverized to fine dust. Coal is both combustible as a bulk material and as coal dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials.

Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing. Combustible dust can pose severe risks, including dust explosions and fires. A combustible dust cloud consists of fine particles suspended in the air, exposed to an ignition source, which leads to a fire or explosion. Combustible dust is created from various materials, including organic substances like wood, grain, metals, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area. Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as cutting, grinding, or transporting materials. These clouds can form in hidden areas such as rafters, ductwork, or equipment, leading to dust explosions.

The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations. Understanding these characteristics is vital for identifying dust hazards, managing the risks associated with explosive dust, ensuring workplace occupational safety and compliance, and preventing a combustible dust explosion.

The NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, provides guidance on combustible dust suppression and dust control. The NFPA 654 Standard is referenced by OSHA’s Combustible Dust National Emphasis Program (NEP) to identify dust hazards and define mitigation strategies that help protect life and property. The standard provides industry-recognized safety practices for flour mills, facility and systems design, process equipment protection, fugitive dust control and housekeeping, ignition source identification and control, fire protection, training and procedures, inspection, and maintenance. The NFPA also specifies using explosion proof equipment and anti static tools and equipment and materials for handling dust, from static electricity issues.

Why Some Metals are More Combustible Than Others

Surface Area and Combustion

Solid metal blocks are typically non-flammable under normal conditions. However, when metals are finely divided into powders, their surface area increases exponentially, making them more susceptible to ignition.

Chemical Properties and Reactivity

Metals like magnesium and aluminum are highly reactive, and readily oxidizing in air. This property, combined with fine particle size, significantly raises their combustibility.

Oxidation Potential and Metal Dust

The Oxidation potential is a critical factor in metal flammability. Once oxidized, metal dust can ignite with even a small spark or heat source, leading to rapid combustion or explosions.

Metal Dust Explosions: A Hidden Hazard

Fine metal dust is one of the most hazardous forms of metal due to its high flammability. Explosions occur when dust is suspended in air and exposed to an ignition source, creating a chain reaction.

Case Studies of Metal Dust Explosions

- AL Solutions Incident (2010): A fatal explosion caused by titanium and zirconium dust killed three workers in West Virginia.

- Hayes Lemmerz Aluminum Explosion (2003): Aluminum dust in a plant ignited, resulting in a fire that destroyed the facility.

Safe Handling and Storage of Metals and Metal Dust

To minimize fire risks, follow these precautions:

- Storage: Keep in a safe dry area, or a container, and ensure both are explosion proof and anti static.

- Dust Control: Use appropriate dust collection systems to prevent accumulation.

- Ventilation: Ensure proper airflow to dilute dust concentrations.

- Ignition Control: Eliminate open flames, sparks, cigarettes, light fixtures, electrical outlets, motors, engines, and static buildup.

- Avoid aerosolization: Do not shake or disperse metal powder near open flames or heat sources.

Safety Guidelines, Compliance, and Best Practices, to Prevent Metal Dust Explosions

Organizations like OSHA and NFPA have established guidelines, including:

- NFPA 484: This standard applies to the production, processing, finishing, handling, recycling, storage, and use of all metals and alloys that are in a form that is capable of combustion or explosion, as well as to operations where metal or metal alloys are subjected to processing or finishing operations that produce combustible powder or dust.

- NFPA 654: Standards for the prevention of fire and dust explosions.

- OSHA’s Combustible Dust NEP: Emphasizes inspections and hazard communication.

Emergency Response Strategies to Metal Explosions incidents include:

- Training: Equip employees with knowledge of safe handling and use of Metal Powder, and emergency protocols.

- Suppression Systems: Install automatic fire suppression and explosion venting systems.

Facilities and people handling metals and metal powder must conduct regular dust hazard analyses, and implement explosion prevention measures. The consequences of Non-Compliance and failure to comply can lead to fines, facility closures, and liability for damages resulting from accidents.

Firefighting Techniques for Metal Fires

Metal fires (Class D fires) require specialized firefighting methods. Water and conventional fire extinguishers are ineffective and can worsen the situation.

Class D Fire Extinguishers

Class D extinguishers use dry powder agents like sodium chloride or graphite to smother metal fires by cutting off oxygen.

Step-by-Step Guidelines

- Evacuate the area to ensure worker safety.

- Identify the metal involved in choosing the appropriate extinguishing agent.

- Apply the dry powder agent to the fire from a safe distance.

- Monitor the area for re-ignition, as metal fires can persist.

A picture of the OSHA Combustible Dust Poster, and Materials that Create Dust in a Manufacturing Facility

A picture of the OSHA Combustible Dust Poster, and Materials that Create Dust in a Manufacturing Facility

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), and the Internet of Things, (IoT), in Managing Metal Powder Dust Explosions and Metal Flammability

The integration of Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) has revolutionized the management of metal powder dust explosions and flammability risks. AI-powered systems can analyze large datasets in real time, identifying patterns and potential hazards that human operators might overlook. For instance, sensors integrated with IoT networks continuously monitor environmental factors such as humidity, temperature, and dust concentration, relaying data to centralized systems for analysis. Using ML algorithms, these systems can predict when conditions are approaching critical thresholds, triggering automated alerts or preventive actions, such as activating ventilation systems or shutting down operations. This proactive approach significantly reduces the likelihood of dust explosions by addressing risks before they escalate.

In addition to prevention, AI, ML, and IoT enhance response capabilities during emergencies. Smart systems can detect the presence of combustible metal dust or a developing fire and automatically deploy fire suppression mechanisms tailored to the specific material involved. For example, IoT-connected Class D extinguishers or suppression agents can be activated precisely where needed, minimizing damage and preventing the spread of fire. Furthermore, predictive maintenance powered by ML ensures that critical equipment, such as dust collection systems and fire suppression units, remains in optimal condition. These technologies not only improve safety but also enhance operational efficiency, enabling industries to manage metal flammability risks with unprecedented precision and reliability.

Conclusion

Understanding the combustibility of metals is essential for ensuring safety in industrial and manufacturing environments. While most solid metals are non-flammable, finely divided metal powders pose significant risks of fire and explosions.

By following safety protocols, implementing preventive measures, and using appropriate firefighting techniques, industries can minimize the dangers associated with metal flammability.

Prioritize safety by educating workers, investing in specialized equipment, and adhering to guidelines from trusted organizations like OSHA and NFPA. Doing so not only protects lives but also ensures operational continuity in hazardous environment

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Metal dust explosions, with a Podcast. Click on the latest Podcast Links: Metal Dust Explosion Loss History, Severity & Practical Considerations and Understanding Your Options For Collecting Combustible Metal Dusts

A picture of Dr. Chris Cloney, an Expert on Combustible Dust Hazard Analysis

A picture of Dr. Chris Cloney, an Expert on Combustible Dust Hazard Analysis

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.