Updated January 6, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Is Ink Flammable?

Ink, a common substance used in various applications from writing to printing, is one such item. But a question that often arises is, “Is ink flammable?” The answer is yes, some inks are flammable, including solvent inks, alcohol inks, and black ink, and near an open flame and high temperatures. However, the flammability of ink varies depending on its composition, particularly the type of solvents used. Some inks are flammable near an open flame, or high temperatures due to the solvents they contain, while others are not. While most inks used in everyday applications and during normal conditions, are not highly flammable, some, especially those with alcohol or oil-based solvents, can pose a fire risk, catch fire, and pose a health hazard. The key hazard is an explosion from the buildup of solvent vapors in the oven or dryer atmosphere. Some inks can also be a hazardous chemical and a health hazard depending on the ingredients.

Understanding the flammability of ink is crucial for safety, especially in settings where bulk quantities are stored or used, near an open flame. Ink is ubiquitous in our daily lives, whether it’s in the form of a ballpoint pen for jotting down notes or printer ink for producing documents. Despite its widespread use, the flammability of ink is not commonly understood, yet it’s a critical aspect for ensuring safety in homes, offices, and industrial settings.

What is Ink?

Ink is a liquid or paste that contains carbon black or Gilsonite, which are both combustible, with a liquid and binder, and pigments or dyes used for coloring surfaces to produce an image, text, or design. Historically, ink has been made from a variety of natural substances, including plant extracts and animal products. Today, modern inks are often synthetic and can be formulated for specific applications, such as writing, printing, or even tattooing.

Chemical Composition of Ink

The chemical composition of ink varies widely depending on its intended use. Ink can be a hazardous chemical catch fire, and can be a health hazard. Generally, ink is composed of:

- Pigments or Dyes: These are the colorants in the ink.

- Solvents: Liquids that dissolve the pigments or dyes and allow the ink to flow.

- Resins: Substances that help the ink adhere to the surface.

- Additives: Various chemicals are added to improve the ink’s performance, such as stabilizers, drying agents, and thickeners.

Flash Point of Ink

The flash point of a substance is the lowest temperature at which it can vaporize to form an ignitable mixture in air. Solvents with low ignite points are more flammable. For example, alcohol-based inks tend to have lower flash points and are therefore more flammable, near an open flame.

The flash point of ink is usually listed in Section 9 of a Safety Data Sheet (MSDS) that complies with Globally Harmonized System, GHS, which is the section on physical and chemical properties. The ignite points of a chemical can be found in a Safety Data Sheet (SDS), formerly known as a Material Safety Data Sheet (MSDS), produced by the chemical’s manufacturer.

The Occupational Safety and Health Administration, OSHA, – Chemical Safety Guidelines Hazard Communication Standard: Safety Data Sheets requires that the chemical manufacturer, distributor, or importer provide Safety Data Sheets (SDSs), (formerly MSDSs or Material Safety Data Sheets), for each hazardous chemical to downstream users to communicate information on these hazards.

Use of an Explosimeter for Monitoring Ink Solvent Vapors

An explosimeter is a small, portable device designed to detect combustible gases within a sample, making it an essential tool for ensuring safety in environments where flammable vapors are present. In industries dealing with ink and printing, solvent vapors can accumulate and create a hazardous atmosphere. The explosimeter works by drawing in air from the environment and analyzing it for the presence of combustible gases. By providing real-time data on gas concentrations, it helps workers identify potential risks and take necessary precautions to prevent fires and explosions. Regular monitoring with an explosimeter ensures that the levels of ink solvent vapors remain within safe limits, thereby protecting both personnel and equipment and preventing a health hazard.

The National Fire Protection Association (NFPA) has established guidelines for monitoring flammable vapor concentrations in industrial settings. According to NFPA 86, continuous analyzers are required to measure the potential flammability of vapor concentrations in any oven or dryer zone exceeding 25% of the Lower Flammable Limit (LFL). This regulation underscores the importance of maintaining strict control over solvent vapor levels to prevent explosive incidents. For facilities using ink solvents, continuous monitoring with devices like explosimeters helps maintain compliance with safety standards and ensures a safer working environment.

Flammable Properties of Different Types of Ink

- Printer Ink

Printer ink, and toner, used in inkjet and laser printers, typically contains water, solvents, pigments, and various additives. Most printer inks are water-based and are not highly flammable. However, solvent-based printer inks, which are used in some industrial printing applications, can be flammable due to their chemical composition. - Pen Ink

Pen ink, such as that found in ballpoint pens, gel pens, and markers, can vary in flammability. Many ballpoint pen inks are oil-based and contain flammable solvents, making them more likely to catch fire. Gel pen inks are typically water-based and less flammable. Marker inks, especially permanent markers, often contain alcohol or other organic solvents, which can be flammable. - Tattoo Ink

Tattoo ink is generally not considered flammable. It is usually made from a combination of pigments and a carrier solution, which can include water, glycerin, or alcohol. The alcohol content in some tattoo inks can make them slightly flammable, but they are not considered a significant fire hazard under normal conditions.

Factors Influencing Ink Flammability

Impact of Solvents on Ink Composition

The flammability of ink is significantly influenced by the solvents used in its composition. Solvents such as alcohols, ketones, and hydrocarbons are commonly used in ink formulations to dissolve pigments and facilitate smooth application. These solvents have varying ignite points, which determine the temperature at which they can vaporize to form an ignitable mixture with air. Solvents with low ignite points, like ethanol and acetone, are highly flammable and can easily ignite if exposed to a spark or open flame, and can be a health hazard.

The Role of Drying Methods and Environments in Affecting Flammability

Drying methods and the environments in which ink is used also play a critical role in influencing its flammability. In industrial printing processes, ink is often dried using heat, UV light, or air-drying methods. Heat drying, while efficient, can increase the risk of ignition if the drying environment is not properly controlled. Excessive heat can cause solvent vapors to accumulate and reach their flammable limits. Additionally, poor ventilation can exacerbate this risk by allowing solvent vapors to concentrate in confined spaces.

Temperature and Pressure Conditions That Can Trigger Flammability

Temperature and pressure conditions are pivotal in determining the flammability of ink. High temperatures can lower the flash point of solvents, making them more prone to ignition. Similarly, high-pressure environments can increase the concentration of solvent vapors in the air, creating a more flammable atmosphere. Industrial settings where ink is used or stored must carefully monitor and control these conditions to prevent accidental ignition. For example, maintaining temperatures below the flash point of the ink’s solvents and ensuring that pressure levels do not allow for excessive vapor concentration are critical safety measures.

Ink as a Combustible Dust

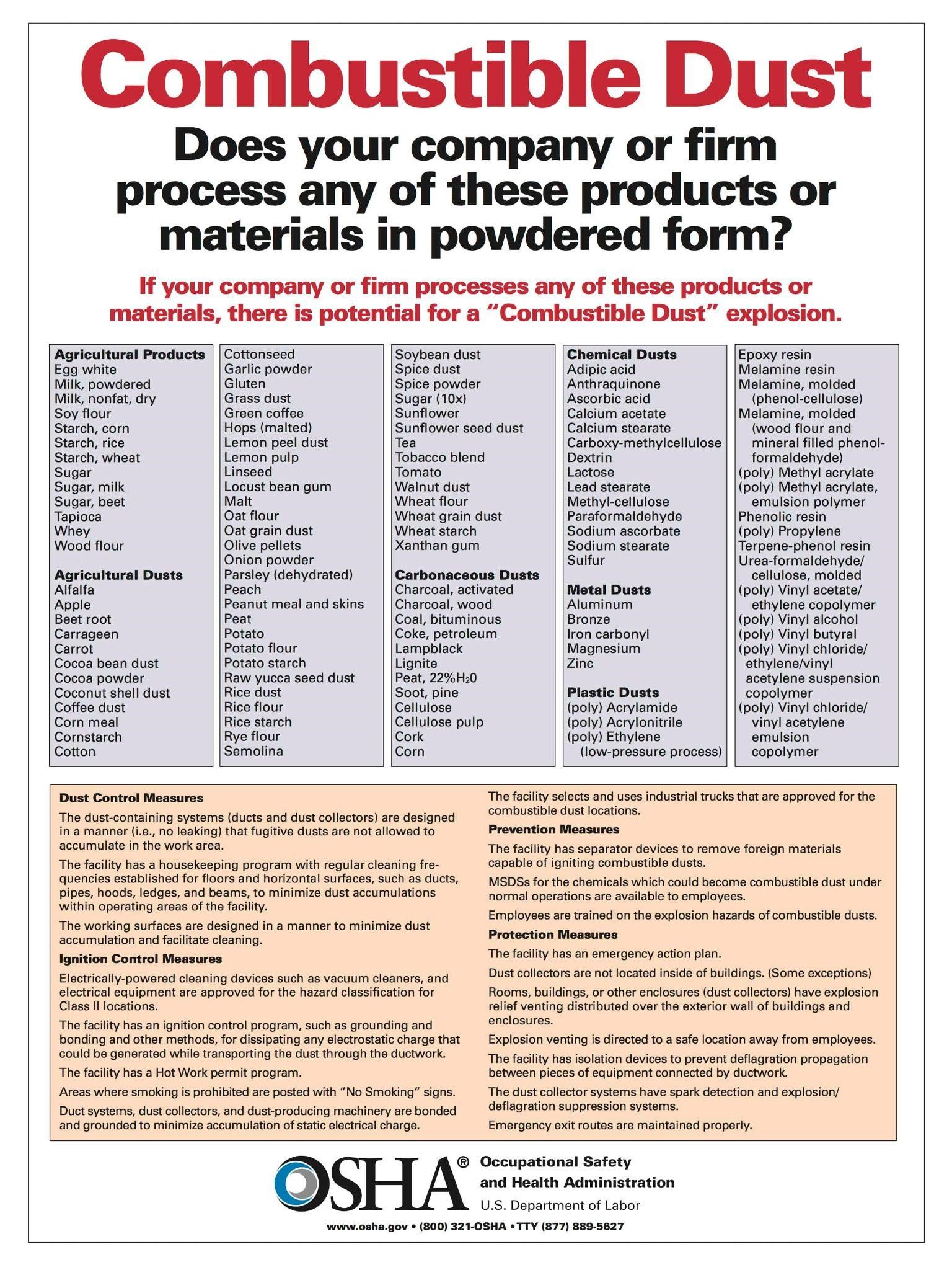

In the realm of industrial safety, combustible dust is a significant concern due to its potential to cause explosions and fires. Ink, particularly in powder form used in certain printing processes such as laser printers and photocopiers, can be considered combustible dust. When these ink powders are dispersed in the air in a fine particulate form, they can create an explosive atmosphere. The primary hazard arises when these particles are ignited, leading to rapid combustion and potentially causing devastating explosions in confined spaces.

The risk associated with ink as combustible dust becomes more pronounced in environments where ink powders are processed, stored, or handled in large quantities. During manufacturing, packaging, or recycling processes, ink particles can become airborne and accumulate on surfaces, creating a dust cloud. If this cloud encounters an ignition source, such as a spark from machinery or static electricity, it can lead to a flash fire or explosion. Therefore, industries that deal with ink powders must implement stringent dust control measures, including proper ventilation, regular cleaning, and the use of explosion-proof equipment.

Safety regulations and guidelines, such as those provided by the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA), highlight the importance of managing combustible dust hazards. Facilities that handle ink powders must conduct thorough risk assessments to identify potential ignition sources and implement control measures to mitigate the risk. This includes using dust collection systems, grounding and bonding equipment to prevent static discharge, and training employees on safe handling practices.

Historical Incidents Involving Ink Fires

There have been several notable incidents involving flammable ink that highlight the importance of understanding and managing its risks. One such case occurred in a printing facility where a spark from an electrical malfunction ignited solvent vapors from ink, resulting in a significant fire. The fire spread rapidly due to the high concentration of flammable vapors and inadequate ventilation, causing extensive damage to the facility and injuring several workers. Another incident involved the explosion of a storage area where large quantities of ink solvents were kept. A static discharge ignited the vapors, leading to a powerful explosion that caused structural damage and required emergency response.

Conclusion

The lessons learned from past ink-related explosions and fires emphasize the critical need for stringent safety measures and regular risk assessments. The flammability of ink varies depending on its composition, particularly the type of solvents used. While most inks used in everyday applications are not highly flammable, some, especially those with alcohol or oil-based solvents, can pose a fire risk.

Key takeaways include the importance of proper ventilation to disperse solvent vapors, the necessity of maintaining equipment to prevent electrical malfunctions, and the implementation of static control measures. Additionally, training employees on the safe handling and storage of flammable inks is essential to prevent accidents. These incidents also underscore the need for compliance with safety regulations, such as those outlined by the NFPA and OSHA, to minimize the risk of flammability and ensure a safe working environment. By learning from these past events, industries can adopt better practices to protect both personnel and property from the hazards associated with flammable ink.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional 3D Printing Ink Dust Explosion Safety information, with a Podcast. Click on the latest Podcast Link: Explosion and Fire Safety in 3D Printing Applications with Jason Reason

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.