Published November 26, 2024 Authors: Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is Cornstarch?

Cornstarch is primarily an organic material, composed of starch molecules, a carbohydrate derived from plants. Chemically, it consists of long chains of glucose molecules that provide unique properties, such as thickening when mixed with water. Cornstarch is a powdered carbohydrate derived from the endosperm of corn kernels. Known for its ability to thicken sauces, polish surfaces, and even aid in industrial manufacturing, cornstarch is a staple in both homes and industries. Cornstarch is a common household and industrial product, praised for its versatility and utility. However, despite its widespread use, many are unaware of the risks associated with its flammability. This article explores the properties of cornstarch that make it flammable, historical dust explosion incidents highlighting its dangers, and the preventive measures necessary to mitigate associated risks.

While its uses are vast, cornstarch poses a significant hazard due to its potential flammability. When suspended in the air, fine cornstarch particles can ignite and cause dust explosions under certain conditions. Understanding these risks is essential for ensuring the safe handling and storage of this material.

- Food production: As a thickening agent in soups, sauces, and desserts.

- Pharmaceuticals: As a filler or binding agent in tablets.

- Industrial processes: For manufacturing adhesives, paper, and bio-based plastics.

Cornstarch is Flammable and is an Explosion Hazard

Yes, cornstarch is flammable and can be explosive. Cornstarch is a combustible dust that can create a dust explosion hazard when dispersed into the air in high concentrations. Yes, cornstarch is flammable under certain conditions. While it is not typically flammable in its solid or bulk form, cornstarch becomes highly combustible when dispersed into the air as fine dust. When airborne, the small particles have a large surface area exposed to oxygen, making them capable of igniting if exposed to an ignition source, such as a spark, flame, or static discharge.

Ignition sources: Cornstarch can burn or explode if there’s an ignition source, such as an open flame, spark, hot surface, electrical equipment, smoking, or static electricity.

Real-world examples: Cornstarch has been used in events like color runs, which can create a fire hazard if the particles are the right size and concentration. In 2015, a fire at a Taiwanese water park was likely caused by overheating colored cornstarch thrown over a crowd. A Holi festival celebrated worldwide, Holi Powder and Coloured Powders such as cornstarch and dyes, are thrown into the air, causing a dust cloud and combustible dust explosion hazard, in crowds of people, with candles, flames, and lighters.

Key Points About Cornstarch Flammability:

- Dust Clouds: Cornstarch forms combustible dust clouds that can ignite and lead to explosions if the right air-to-fuel ratio exists. An example is throwing bulk organic material into the air, which forms a dust cloud.

- Ignition Temperature: The temperature required to ignite cornstarch dust is relatively low, making it a potential hazard in industrial and processing environments.

- Static Electricity: Cornstarch can burn or explode with an ignition source, such as an open flame, spark, hot surface, electrical equipment, smoking, or static electricity.

- Confined Spaces: Dust explosions are more dangerous when cornstarch dust accumulates in confined spaces, as the pressure can lead to secondary explosions.

Cornstarch as a Combustible Dust

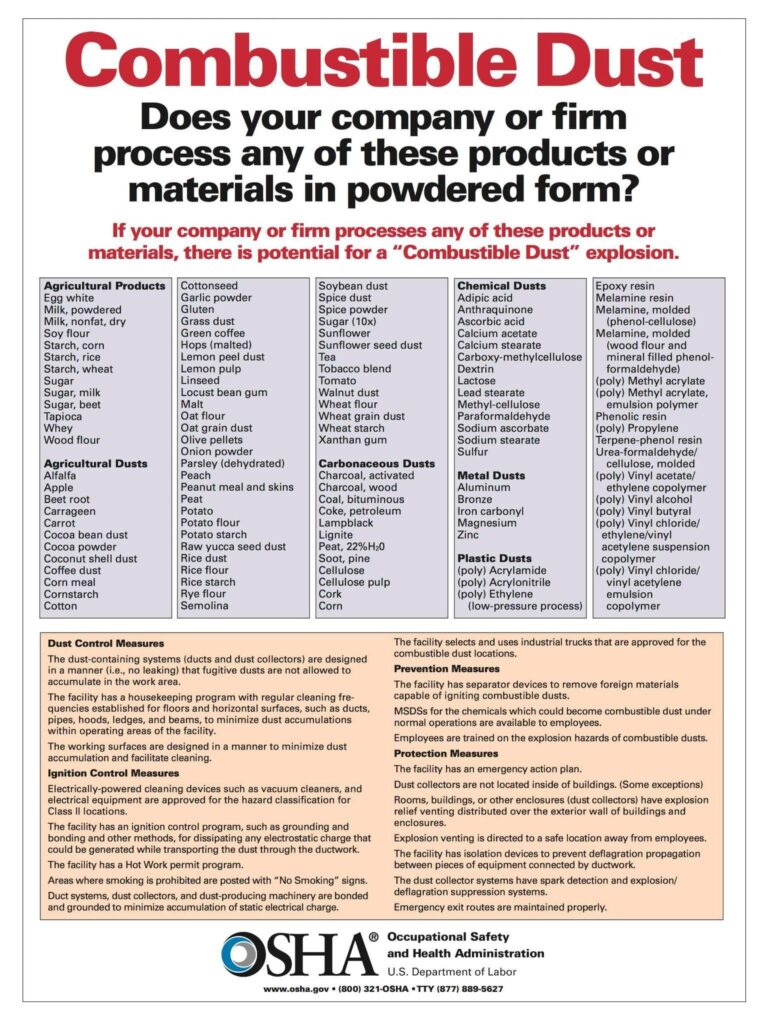

Cornstarch is considered combustible dust, and other combustible materials and products, such as paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are not combustible in larger bulk material pieces but can be when pulverized to fine dust. Coal is both combustible as a bulk material and as coal dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials.

Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing. Combustible dust can pose severe risks, including dust explosions and fires. A combustible dust cloud consists of fine particles suspended in the air, exposed to an ignition source, which leads to a fire or explosion. Combustible dust is created from various materials, including organic substances like wood, grain, metals, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area. Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as cutting, grinding, or transporting materials. These clouds can form in hidden areas such as rafters, ductwork, or equipment, leading to dust explosions.

The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations. Understanding these characteristics is vital for identifying dust hazards, managing the risks associated with explosive dust, ensuring workplace occupational safety and compliance, and preventing a combustible dust explosion.

The NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, provides guidance on combustible dust suppression and dust control. The NFPA 654 Standard is referenced by OSHA’s Combustible Dust National Emphasis Program (NEP) to identify dust hazards and define mitigation strategies that help protect life and property. The standard provides industry-recognized safety practices for flour mills, facility and systems design, process equipment protection, fugitive dust control and housekeeping, ignition source identification and control, fire protection, training and procedures, inspection, and maintenance. The NFPA also specifies using explosion proof equipment and anti static tools and equipment and materials for handling dust, from static electricity issues.

Historical Incidents Involving Cornstarch and Analysis of Root Causes

Several incidents involving cornstarch had dust explosions:

- The Douglas Starch Works Plant Explosion of 1919: a massive corn starch dust explosion rocked the building, the walls collapsed, pieces of the factory were hurled up to two miles away, and smoke billowed in the evening sky.

- Starch Factory Explosion in China (2010): According to China Daily, the Qianhuangdao Lihua Starch Co Ltd in Funing County, Qinhuangdao, had a starch dust explosion and 18 workers died at the scene and 50 others were injured. However, the death toll rose to 19.

- New Taipei Water Park Explosion, Colour Play Asia Party (June 2015): a social event, turned into a tragedy, with a starch dust explosion, that killed 15 people, and injured nearly 500 others.

Analysis and Outcomes

These incidents revealed:

- A lack of awareness regarding dust explosion risks.

- Insufficient preventive measures, such as poor ventilation and inadequate dust collection systems.

- Post-incident investigations led to improved safety standards, including better dust collection technology and employee training on combustible dust hazards.

Factors Contributing to Cornstarch Combustion

A dust explosion occurs in two stages:

- Primary Explosion: An ignition source sets off a small explosion in a confined area.

- Secondary Explosion: The primary blast disperses more dust, triggering a larger explosion.

Specific Factors for Cornstarch Combustion

- Particle Size: Fine particles burn more rapidly due to increased oxygen exposure.

- Air-to-Fuel Ratio: The right concentration of dust and air forms an explosive mixture.

- Static Electricity: A spark from static discharge can serve as an ignition source.

- Environmental: Conditions and factors such as humidity, ventilation, and the presence of oxidizing agents can influence the likelihood of ignition.

Safety Guidelines, Compliance, and Best Practices, to Prevent Cornstarch Dust Explosions

Organizations like OSHA and NFPA have established guidelines, including:

- NFPA 654: Standards for the prevention of fire and dust explosions.

- OSHA’s Combustible Dust NEP: Emphasizes inspections and hazard communications.

Best Practices for Storage, Handling, and Processing include:

- Storage: Keep in a safe dry area, or a container, and ensure both are explosion proof and Anti Static.

- Dust Control: Use appropriate dust collection systems to prevent accumulation.

- Ventilation: Ensure proper airflow to dilute dust concentrations.

- Ignition Control: Eliminate open flames, sparks, cigarettes, light fixtures, electrical outlets, motors, engines, and static buildup.

Emergency Response Strategies include:

- Training: Equip employees with knowledge of emergency protocols.

- Suppression Systems: Install automatic fire suppression and explosion venting systems.

Facilities and people handling cornstarch must conduct regular dust hazard analyses, and implement explosion prevention measures. The consequences of Non-Compliance and failure to comply can lead to fines, facility closures, and liability for damages resulting from accidents.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), and the Internet of Things, (IoT), in Managing Cornstarch Dust Explosions

Technological advancements, particularly the integration of Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT), are revolutionizing the management of combustible dust hazards, including cornstarch dust explosions. AI-powered systems can analyze large volumes of data collected from sensors placed throughout industrial facilities to detect patterns and anomalies that signal dust buildup or dangerous conditions. These predictive analytics allow for real-time monitoring and early warnings, significantly reducing the likelihood of incidents. For example, AI algorithms can analyze factors like particle concentration, temperature changes, and airflow disruptions to provide actionable insights, enabling operators to address hazards before they escalate.

The Internet of Things (IoT) further enhances safety by creating interconnected networks of devices that continuously monitor and control environmental conditions. IoT-enabled sensors can measure dust levels, humidity, and pressure across various points in a facility, transmitting data to a centralized system for analysis. Machine learning algorithms then refine this data over time, improving the system’s accuracy in predicting risks. In case of an emergency, IoT systems can automatically activate safety measures such as dust suppression systems or explosion venting, ensuring a swift response. Together, AI, ML, and IoT offer a proactive and automated approach to managing cornstarch dust explosions, reducing human error, and improving workplace safety.

Conclusion

Cornstarch, while a versatile and widely used material, poses significant risks due to its flammability. Understanding the properties that contribute to these risks, the factors leading to combustion, and the historical precedents of cornstarch-related incidents is critical for ensuring safety.

Adopting preventive measures, adhering to regulatory standards, and fostering awareness can mitigate the risks associated with combustible dust like cornstarch. It is imperative for industries and individuals handling cornstarch to prioritize safety, educate themselves on the hazards, and implement best practices.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Starch dust explosions, with a Podcast. Click on the latest Podcast Link: Incident Update – 2021 Potato Starch Explosion in Tuas, Singapore

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

VisitDust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art fire and explosion protection.