Updated February 13, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A picture of a Combustible Dust Fire and Hazard, inside a Flour Processing Facility

Flour Dust as a Combustible Dust

In the flour mills, milling, food industry, and baking industries, flour dust may seem harmless, but beneath its powdery appearance lies a potentially catastrophic risk of flour dust explosions. Unfortunately, flour can explode and these explosions, triggered by the ignition of fine dust particles forming a dust cloud, and suspended in the air, have wreaked havoc on facilities, causing immense damage to property and endangering lives. Flour, when in dust form, can be a highly combustible material. A risk of flour explosions occurs when a cloud of flour dust particles in the air, such as a dust cloud, is ignited by a spark, flame, or another ignition source. The Occupational Safety and Health Administration, (OSHA), identifies Flour as Combustible Dust. According to the Occupational Safety and Health Administration (OSHA), Combustible dust is defined as: “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations.” Fine flour dust particles generated during various stages of flour production, such as grinding, pulverizing, blending, and mixing, constitute the primary source of dust in these facilities and can make flour explode. Dust is considered to be a solid material that is composed of distinct particles, regardless of their shape, particle size, or chemical composition.

The presence of combustible dust represents a significant peril. Flour dust is a fine particulate matter that is often a byproduct of processing and handling grains, flour mills, the food industry, or agricultural materials like wheat, corn, barley, and rice, and is inherently combustible. The nature of these materials, when finely ground, such as flour, during various processing stages in flour mills, in a grain elevator, bucket elevators, or stored in silos, elevates the risk of dust accumulation and an explosive atmosphere. These particles, when suspended in the air in certain concentrations, as a dust cloud, can ignite swiftly when exposed to an ignition source, or hot surfaces, triggering dust explosions or fires, a deflagration hazard, and a chain reaction with devastating consequences. This dust, composed of organic materials, and other combustible materials such as coal dust, and metal dusts, possesses the potential for rapid combustion when exposed to ignition origins, setting the stage for dust explosions or fires within grain processing facilities, in a grain elevator, silos, or storage areas.

Definition of Flour Dust Explosions

Flour explosions are a subset of combustible dust explosions, characterized by the rapid combustion of fine flour particles in the presence of an ignition source. A flour explosion occurs when flour dust is dispersed in the air at high concentrations, these particles form an explosive mixture that, when ignited, can lead to a chain reaction, from a dust cloud and deflagration. Combustible dust refers to any finely divided solid material that presents a fire or explosion hazard when suspended in air, with a greater surface area, under certain conditions. Flour dust, a byproduct of flour mills, a mill complex, storage bins, milling, the food industry, and processing operations, falls into this category due to its inherent combustibility and the risk of flour explosions. Other combustible materials and dusts such as coal dust, and metal dust, can also be an explosion hazard.

The significance of addressing flour dust explosion risks cannot be overstated. Beyond the immediate threats to life and property, these incidents can have far-reaching consequences, with explosive force, including financial loss, reputational damage, and legal liabilities. By understanding the science behind flour explosions as an explosion hazard, and implementing effective prevention measures, industries can mitigate these risks and ensure the safety of their operations.

👉 Prevent Dust Explosions: Register Today For Combustible Dust Training, with Dust Safety Science!

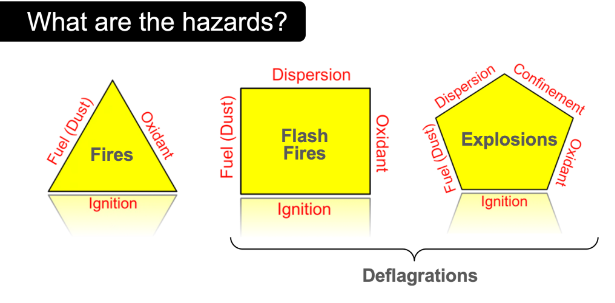

A picture of the Combustion Triangle, Square, and Pentagon, and the Pentagon Five Elements needed for combustible Flour dust to catch fire and cause an explosion.

Understanding Flour Dust Explosions

The science behind flour explosions occurs when three elements come together: fuel (flour dust), oxygen (present in the air), and an ignition source. When ignited, the fine small particles rapidly oxidize, releasing energy through heat and pressure, resulting in an explosion hazard. The five elements responsible for a flour explosion (dust, ignition source, confined space, dispersion, and oxygen).

Several factors influence the likelihood and severity of flour explosions:

- Particle Size: Finer particles pose a greater risk as they have a larger surface area and are more easily dispersed in the air, forming an explosive mixture.

- Moisture Content: Moisture acts as a binder, reducing the dispersibility of flour particles and mitigating the risk of explosion. Conversely, dry conditions increase the likelihood of combustion.

- Airborne Concentration Levels: High concentrations of flour dust, such as fine dust, in the air, create an ideal environment for combustion. Minimum Explosive Concentration, (MEC), Determines the minimum quantity of dust required, when dispersed, to form a flammable atmosphere. Proper ventilation and dust control measures are essential for maintaining safe airborne levels.

- Ignition Sources: Common ignition sources and heat sources include sparks, an open flame, hot surfaces, electrical equipment, static electricity, and friction. Eliminating or controlling these sources is crucial for preventing explosions with intrinsically safe equipment and explosion proof equipment.

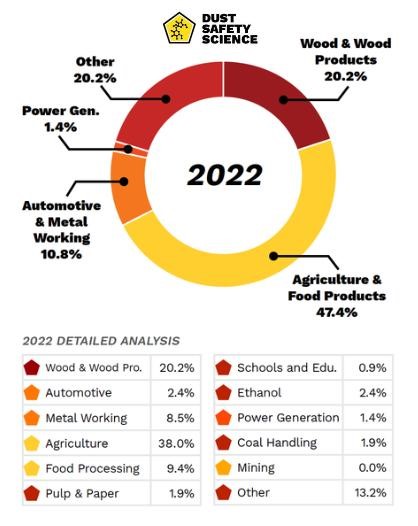

A picture of a detailed analysis and percentages of several Industries, including Grain and Agriculture and Food Products, affected by Combustible Dust, from Dust Safety Science

Historical Examples of Flour Dust Explosions

Dust explosion and incidents, continue to occur worldwide and in the flour, and flour mills industry, as presented in this combustible dust research and incident database from Dust Safety Science. In addition, the most prevalent industries’ statistics regarding dust incidents are also captured in this Annual Incident Report Database, from Dust Safety Science. During 2022, the Grain and Agriculture dust occurred in 38% of dust incidents. In addition, the Dust Safety Science Podcast educates the public on the Incident Update – 2021 Flour Dust Explosion in Savannah, Georgia Some of the historic flour explosions and incidents include:

- Giacomelli’s Bakery Warehouse (1785): According to historical accounts from The Repertory of Arts and Manufactures, Volume 2, Publisher G. & T. Wilkie., 1795 Original, from the New York Public Library, Digitized Aug 19, 2011, Count Carlo Ludovico Morozzo di Bianzè investigated and recorded December 14th, 1785. The flour dust explosion occurred when one worker, was pouring flour into a bolter, from a second floor level of the bakery. This is the 1st recorded dust explosion, that occurred at an Italian flour mill when flour dust came in contact with a mounted lamp, which injured two workers.

- Tradeston Flour Mill (1872): According to Wikipedia, in 1872 the Tradeston Flour Mills, in Glasgow, Scotland, exploded. Eighteen people died, and at least sixteen were injured. An investigation suggested that the explosion was caused by the grain feed to a pair of millstones stopping, causing them to rub against each other, resulting in a spark or fire igniting the grain dust in the air. That fire was then drawn by a fan into an “exhaust box” designed to collect grain dust, which then ignited, causing a second explosion that destroyed the building. At the time, there were general concerns about similar incidents worldwide, so the incident and investigation were widely reported across the world.

- The Great Mill Disaster (1878): Also known as the Washburn A Mill explosion, occurred on May 2, 1878, in Minneapolis, Minnesota, United States Two professors from the University of Minnesota, S. F. Peckham and Louis W. Peck, later confirmed that abundant flour dust had been the cause of the explosion after reviewing controlled experiments regarding flour dust combustion They concluded that two dry millstones had rubbed against each other and caused a spark that ignited the dust, causing the explosion.

Studying previous flour explosions provides valuable insights into their causes, contributing factors, and preventive measures. Industries can identify potential hazards and implement effective risk mitigation strategies by analyzing these incidents

Historical incidents of combustible explosions within the flour and flour mills industry provide the continuous risks inherent in this vital sector. From grain silos to processing facilities, these incidents have highlighted the devastating consequences of dust accumulation, dust build up, dust collection, and ignition, and how flour explodes. Similar bulk food dust explode in dust form include powdered milk, cocoa powder, and starches such as cornstarch or potato starch. Each explosion serves as a stark reminder of the need for continuous vigilance, robust safety protocols, and proactive risk management strategies to prevent future a flour explosion.

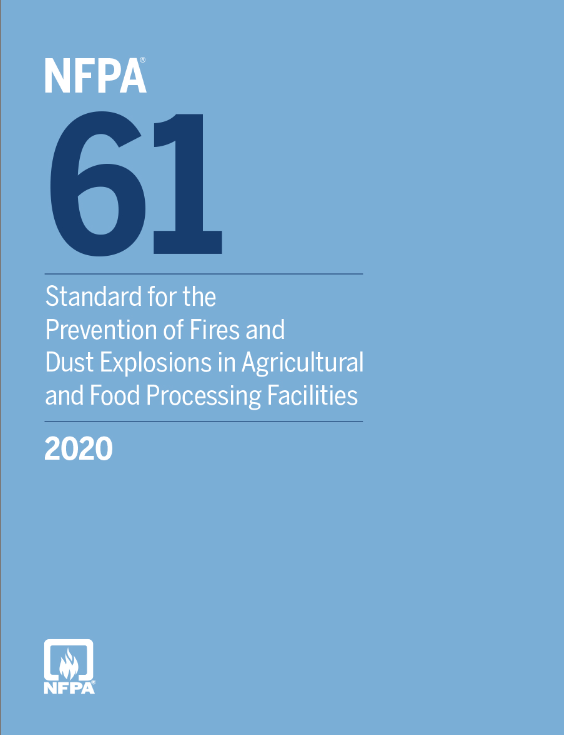

A picture of the NFPA 61 Guide and the NFPA 61 Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

Regulatory Guidelines and Industry Standards for Flour Explosions

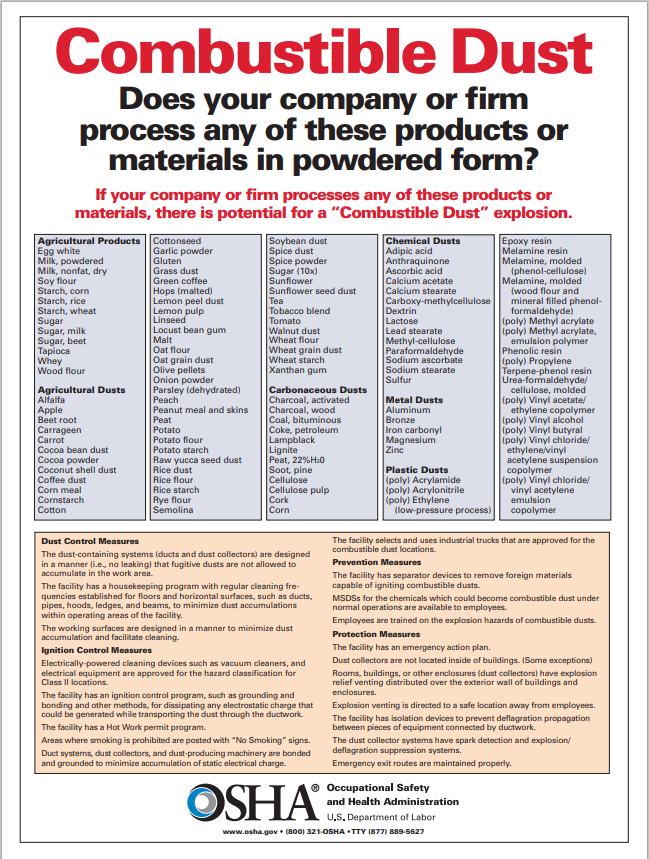

Regulatory agencies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established guidelines and standards to address flour dust hazards. These regulations outline requirements for dust control, dust build up, explosion proof equipment, hazard communication, training, and emergency preparedness.

These Industry organizations and standards bodies have developed specific guidelines for managing flour dust hazards, including proper ventilation, dust containment, explosion proof equipment design, and employee training. OSHA and the National Fire Protection Association, NFPA, play a crucial role in promoting workplace safety and preventing dust explosions through enforcement, education, and collaboration with industry stakeholders. By adhering to regulatory requirements and industry best practices, including the use of explosion proof equipment, companies can reduce the risk of flour explosions and ensure a safe working environment.

Disaster Management, Response, and Prevention Strategies for Flour Dust Explosions

Effective emergency response planning and hazard prevention are essential for minimizing the impact of flour explosions and ensuring the safety of personnel. This includes developing evacuation procedures, establishing communication protocols, and conducting regular drills to test response readiness. Investing in comprehensive training programs and emergency preparedness initiatives is critical for equipping employees with the knowledge and skills to respond effectively to flour explosions. By empowering workers to identify hazards and take appropriate action, companies can enhance safety and reduce the likelihood of accidents. Implementing engineering controls such as enclosed processing equipment, dust collection systems, and explosion venting can effectively reduce dust exposure and minimize the risk of explosions.

- Dust Collection Systems: Proper dust collection systems are essential for controlling airborne dust levels and preventing the large amounts and accumulation of combustible material in confined spaces. Regular maintenance and inspection of these confined space systems are necessary to ensure optimal performance and compliance with safety standards.

- Housekeeping Practices for Controlling Dust Levels

Good housekeeping practices, including regular cleaning of surface area of equipment, in a confined space, such as ventilation system or dust collection system, electrical equipment, and work areas, are essential for controlling dust levels and preventing ignition and heat sources, from coming into contact with combustible material. - Intrinsically Safe Equipment and Spark Prevention

Using intrinsically safe, explosion proof equipment and implementing spark prevention measures can significantly reduce the risk of ignition in flour mills, processing, flour production, and handling operations. This includes grounding equipment, using spark-resistant materials, and implementing static electricity control measures are required for industrial environments.

👉 Prevent Dust Explosions: Register Today For Combustible Dust Training, with Dust Safety Science!

Technological Innovations in Dust Explosion Prevention

Advancements in monitoring and detection technology have enabled early identification of potential dust hazards, allowing for timely intervention and risk mitigation. These systems include dust layer laser measurement, equipment sensors, artificial intelligent software, thermal imaging cameras, and remote monitoring platforms that provide real-time insights into dust levels and atmospheric conditions.

In addition, explosion suppression, explosion proof, and isolation systems can effectively mitigate the impact of explosions by containing and extinguishing the fireball before it can propagate throughout the facility. These systems employ fast-acting suppression agents and isolation barriers to minimize damage and protect personnel and assets.

Technology plays a pivotal role in enhancing safety protocols and preventing explosions through innovative solutions such as predictive analytics, machine learning, and automation. By leveraging data-driven insights and advanced monitoring capabilities, companies in industrial environments can proactively identify risks and implement targeted interventions to enhance safety and prevent explosions.

A picture of the OSHA Combustible Dusts and Products Producing a Dust Explosion

Conclusion

Combustible dust incidents continue to pose significant risks worldwide, particularly in industries such as the flour and flour mills industry. The data compiled in the Dust Safety Science research and incident database sheds light on the prevalence and severity of these incidents, with the Grain and Agriculture Industry accounting for 38% of reported incidents in 2022. Additionally, historic events such as the flour dust explosion at the Giacomelli’s Bakery Warehouse of 1785, the dust explosion at the Tradeston Flour Mill in 1872, and the flour dust explosion at the Great Mill Disaster of 1878, serve as poignant reminders of the catastrophic consequences of dust explosions and incidents. Similar bulk food dust explode in dust form include powdered milk, cocoa powder, and starches such as cornstarch or potato starch. These incidents underscore the critical importance of proactive safety measures and ongoing education to prevent future dust explosion tragedies. OSHA and the National Fire Protection Association, NFPA, play a crucial role in promoting workplace safety from explosive dusts, and combustible materials, and to prevent flour dust explosions, through enforcement, education, and collaboration with industry stakeholders.

Through incident analysis, it becomes evident that factors such as dust accumulation from flour dust particles, a flour dust cloud, confined spaces, dust collection equipment malfunction, and ignition issues such as static electricity, contribute to the occurrence and severity of these incidents. However, amidst the statistics, there is hope in the form of education, lessons learned, and preventive measures implemented. Industry-wide initiatives, improved explosion proof equipment design, enhanced ventilation systems, and comprehensive training programs have all played pivotal roles in mitigating the risks associated with explosive dusts and dust particles, and the risk of a flour explosion, in the flour and flour mills industry.

About Dust Safety Science

For more from Dr. Chris Cloney on Dust explosions in the Flour and Flour Mill Industry, visit this podcast episode: Incident Update – 2021 Flour Dust Explosion in Savannah, Georgia

A picture of Dr. Chris Cloney, an Expert on Combustible Dust Hazard Analysis

Resources:

👉 Prevent Dust Explosions: Register Today For Combustible Dust Training, with Dust Safety Science!

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.