Updated April 2, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Learn more about fire tetrahedron and how it contributes to fires.

What is the Fire Tetrahedron?

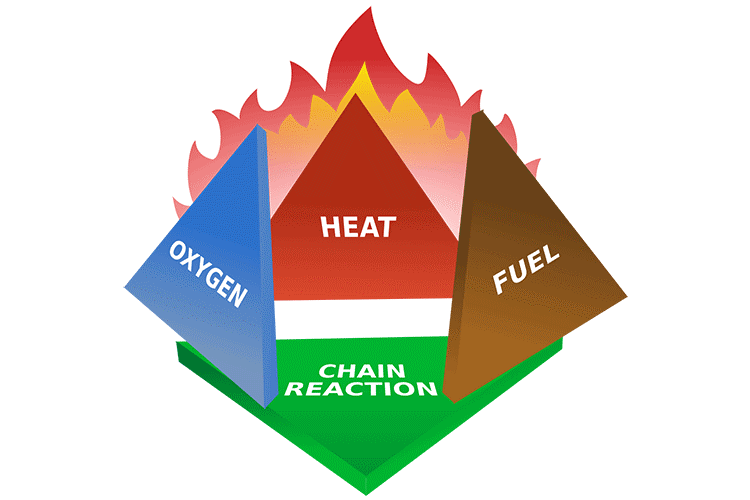

The fire tetrahedron is a model that describes the elements, i.e. oxygen, heat, fuel, and a chemical chain reaction, required for a fire to occur and sustain itself. Essentially, it’s a pyramid-like diagram where each side represents one of these components, meaning if any of the components is removed, the fire will be extinguished. The fire tetrahedron consists of four components:

- Fuel – A combustible material that burns.

- Heat – The energy necessary to raise the material’s temperature to its ignition point.

- Oxygen – An oxidizer that supports the combustion process.

- Chemical Chain Reaction – The process that perpetuates combustion once it has started.

According to Wikipedia, the addition of the chemical chain reaction distinguishes the fire tetrahedron from the simpler fire triangle, which only includes fuel, heat, and oxygen. While the fire triangle explains how a fire starts, the tetrahedron reveals how a fire continues to burn once ignited. This fourth component is crucial because fire suppression strategies often target breaking this chain reaction, effectively extinguishing the fire.

Learn how to be safer in your workplace.

TABLE OF CONTENTS

Understanding the Fire Triangle and Fire Tetrahedron

Fire Suppression and Safety Measures

Importance of the Fire Tetrahedron in Fire Safety and Fire Behavior

The Fire Tetrahedron in Industrial Settings

Case Studies: Practical Applications of the Fire Tetrahedron

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), and the Fire Tetrahedron Components

Conclusion

About Dust Safety Science

Understanding the Fire Triangle and Fire Tetrahedron

Fire needs specific conditions to sustain itself. To understand how they ignite and how they can be extinguished, you need to know the elements of the fire in the fire triangle and fire tetrahedron.

Let’s break them down:

The Fire Triangle

The fire triangle needs three essential elements to start a fire:

- Heat: Provides the energy to reach a substance’s ignition temperature.

- Fuel: Any combustible material, like wood, paper, or flammable liquid fire.

- Oxygen: Reacts with fuel and heat to support combustion action.

Fire ceases to burn when one of these components is absent.

The Fire Tetrahedron

The fire tetrahedron still has the elements of the fire triangle but adds a fourth element:

- Chemical Chain Reaction: It generates additional heat energy, which lets fire spread and has self-sustaining chemical reaction sequences that keep it burning.

Fire Triangle vs. Fire Tetrahedron: Key Differences

|

Feature |

Fire Triangle |

Fire Tetrahedron |

|

Number of elements |

Three |

Four |

|

Explanation |

Basic model of fire occurrence |

More advanced model |

|

Emphasis |

Focuses on fire’s physical components |

Includes chemical chain reactions |

|

Fire Suppression |

Removing any of the three elements stops the fire |

Fire extinguishes when the chemical chain reaction is broken |

Detailed Explanation of Each Component

1. Heat

Its energy starts and sustains combustion and must reach the ignition temperature of a substance. Fire blankets, cooling agents, or water can remove heat.

2. Fuel

This could be any combustible material, from solids to liquids and gases. Removing fuel prevents further heat combustion.

3. Oxygen

It’s usually present in the air at 21% concentration. Fire suppression systems reduce oxygen levels and put out the fire.

4. Chemical Chain Reaction

This lets fire sustain itself by generating sufficient heat and free radicals. Dry chemicals can disrupt the combustion process.

Fire Suppression and Safety Measures

Understanding how the fire tetrahedron works is essential for preventing and suppressing fire. The National Fire Protection Association recommends these actions for fire safety:

- Use fire blankets to remove oxygen and heat from small fires.

- Use chemical extinguishers to put out the chemical chain reaction.

- Eliminate fuel sources and use foam-based extinguishing agents to control flammable liquid fires.

Historical Background of The Fire Tetrahedron

The concept of the fire triangle dates back to early fire science, providing a basic framework for understanding combustion. However, as research advanced, fire scientists recognized the importance of the chemical reactions that sustain fires. By adding the chemical chain reaction to the model, the fire tetrahedron was developed, offering a more sophisticated and accurate depiction of fire behavior.

Fire science is crucial in understanding and mitigating the risks associated with fires. From domestic incidents to industrial accidents, fire prevention and control require a deep understanding of how fires ignite, grow, and can be extinguished. This knowledge is vital in protecting lives, property, and the environment.

At the core of fire science is the fire tetrahedron, an evolution from the traditional fire triangle. While the fire triangle highlights three essential components—heat, fuel, and oxygen—the fire tetrahedron introduces a fourth, equally critical component: the chemical chain reaction. This addition provides a more comprehensive understanding of fire behavior and informs modern fire safety practices.

This development was particularly important in industrial and high-risk environments, where fires could not be adequately controlled by simply removing one of the three components of the triangle. The tetrahedron’s recognition of chemical reactions helped evolve firefighting strategies and fire safety protocols.

Components of the Fire Tetrahedron

- Fuel: Fuel refers to any material that can undergo combustion. In fire science, fuels are classified into three main types: solid, liquid, and gaseous. Common solid fuels include wood, paper, and textiles, while flammable liquids might include gasoline, oil, and certain chemicals. Gases such as propane and natural gas also serve as fuels. In a fire, fuel serves as the source of energy, sustaining the combustion process. The availability and amount of fuel directly affect how long a fire can burn. For example, a forest fire can spread rapidly because of the abundance of fuel, such as dry leaves and trees.

- Heat: Heat is the energy that raises the temperature of a material to its ignition point, where it begins to burn. Sources of heat can vary, including friction, electrical energy, chemical reactions, or open flames. For a fire to start, there must be enough heat to initiate combustion. Once the fire has ignited, heat continues to play a role in maintaining and spreading the fire by transferring energy to nearby materials, causing them to reach their ignition points. Understanding how heat transfers—from conduction, convection, or radiation—is key to managing fire risks and preventing fire spread.

- Oxygen: Oxygen is the oxidizer that supports the combustion process. In most fires, oxygen comes from the surrounding air, which contains about 21% oxygen. Fires thrive when there’s an adequate oxygen supply, and removing or reducing oxygen can smother a fire. Oxygen concentration directly affects fire intensity. In environments with higher oxygen levels, fires burn more intensely, while fires in oxygen-limited environments (such as in sealed containers or under water) may struggle to sustain combustion.

- Chemical Chain Reaction: The chemical chain reaction is the fourth component of the fire tetrahedron. Once a fire starts, the chain reaction sustains it by continuously generating heat, which, in turn, keeps the fuel burning and the combustion process going. Fire suppression strategies often target this chain reaction. For example, halon fire extinguishers work by interrupting the chemical reaction, effectively stopping the fire without needing to remove heat, fuel, or oxygen. This makes the chemical chain reaction a crucial aspect of fire science, especially in industrial settings where simply removing one of the other components may not be feasible.

Equip yourself with important knowledge about workplace safety.

Importance of the Fire Tetrahedron in Fire Safety and Fire Behavior

The fire tetrahedron provides a more complete understanding of how fires behave and sustain themselves. While the fire triangle helps explain how fires start, the tetrahedron gives a fuller picture by including the chemical chain reaction. This holistic approach is essential in modern fire prevention and suppression, ensuring that all potential aspects of a fire are considered.

For instance, a fire might continue burning even after its fuel or oxygen supply is reduced, as the chain reaction sustains it. By addressing all four components, fire safety professionals can implement more effective fire prevention and firefighting strategies.

Application of the Fire Tetrahedron in Firefighting Techniques

Firefighting strategies are heavily influenced by the fire tetrahedron. For instance, water is often used to cool the fire by removing heat, while foam or other chemical agents can be used to cut off oxygen or interrupt the chemical chain reaction. Understanding the tetrahedron allows firefighters to select the most appropriate suppression method for a given situation.

In some cases, breaking the chain reaction is the most efficient way to extinguish a fire, especially in situations involving electrical fires or flammable gas. Techniques such as using dry chemicals or gas suppression systems target this specific component of the fire tetrahedron.

Role of the Fire Tetrahedron in Fire Safety Education

Educating employees and the public about the fire tetrahedron is crucial for enhancing fire safety awareness. By understanding the four components, individuals can take steps to prevent fires before they start or act swiftly in the event of a fire.

For example, in workplace safety training, explaining the tetrahedron helps employees recognize potential hazards, such as flammable materials or ignition sources, and take preventive measures.

The Fire Tetrahedron in Industrial Settings

A. Relevance in High-Risk Industries

Industries such as chemical manufacturing, oil and gas, and food processing are particularly vulnerable to fires. Understanding the fire tetrahedron is vital in these environments, where fires can spread rapidly and cause severe damage.

In high-risk industries, fire prevention programs often involve controlling fuel sources, managing heat production, and ensuring that oxygen levels are kept in check. By addressing all four components, companies can implement comprehensive fire prevention and mitigation strategies.

B. Combustible Dust and the Fire Tetrahedron

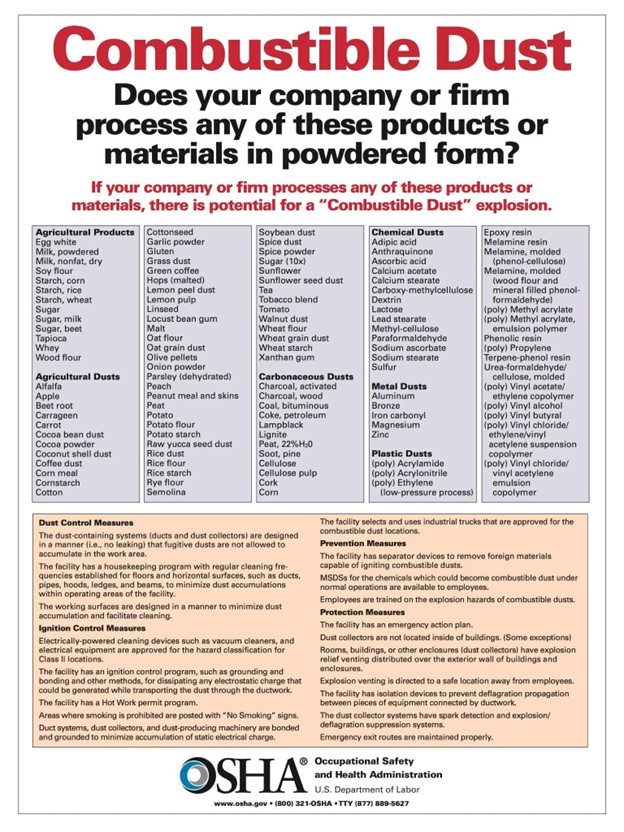

Combustible dust is a significant hazard in industries like agriculture, food processing, and woodworking. Dust particles can ignite when exposed to heat, oxygen, and a fuel source, resulting in dangerous explosions. The fire tetrahedron plays a key role in understanding and preventing these incidents.

Combustible dust is created from a variety of materials, including organic substances like grain, metals, wood, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area. Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing.

Combustible flour dust may seem like an innocuous byproduct of industrial processes, but in certain conditions, it can pose severe risks, including dust explosions and fires. Understanding the formation, identification, and risks associated with combustible dust clouds is crucial for safety management in industries such as agriculture, farming, manufacturing, woodworking, and metalworking.

Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as pouring, sifting, cutting, grinding, or transporting materials. These clouds can accumulate over time in hidden areas such as rafters, ductwork, or equipment, leading to dangerous buildup.

Managing combustible dust is identifying where it tends to accumulate. Dust can settle on surfaces such as floors, beams, ledges, and machinery, making it essential to inspect these areas regularly.

Key strategies to identify accumulation points include:

- Perform a Dust Hazard Analysis

- Regular visual inspections.

- Inspect confined spaces, overhead piping, beams, and suspended ceilings.

- Reviewing areas of low airflow, where dust may collect.

- Monitoring facility changes that could increase dust exposure (e.g., changes in production processes).

C. Fire Prevention and Mitigation Strategies

Fire prevention in industrial settings involves engineering controls, safety protocols, and emergency planning. For example, in oil refineries, fire prevention strategies might include maintaining proper ventilation to control oxygen levels or using automatic suppression systems to break the chemical chain reaction.

By applying the fire tetrahedron model, industries can design effective fire safety systems that minimize the risk of fires and explosions.

Case Studies: Practical Applications of the Fire Tetrahedron

-

Case Study 1: Industrial Fire Suppression

In an industrial fire where chemicals were burning, firefighters successfully extinguished the fire by focusing on breaking the chemical chain reaction. By using specific fire retardants, they were able to stop the combustion process without needing to deplete the oxygen supply or cool the environment.

-

Case Study 2: Combustible Dust Explosion Prevention

In a food processing plant, combustible dust levels were reduced by controlling ventilation and managing potential ignition sources. The facility’s fire prevention program was based on the fire tetrahedron, addressing all four components to prevent dust from becoming a fire hazard.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), and the Fire Tetrahedron Components

Recent advancements in AI, ML, and the Internet of Things (IoT), and Machine Learning (ML) are transforming fire detection and prevention by enhancing our understanding of the fire tetrahedron’s components—fuel, heat, oxygen, and the chemical chain reaction. AI-powered systems can analyze vast data sets from various sources, such as weather patterns, sensor data, and historical fire incidents, to predict potential fire risks. This predictive capability allows for proactive fire prevention measures, such as adjusting ventilation to control oxygen levels in high-risk areas or identifying overheating machinery that could serve as an ignition source. Additionally, AI can identify flames or smoke through video feeds, enabling real-time fire detection in both residential and industrial environments.

IoT-enabled sensors further revolutionize fire prevention by providing continuous monitoring of environmental conditions. These smart sensors can detect changes in temperature, gas levels, and air quality, sending real-time alerts to centralized systems when conditions indicate a potential fire risk. This integration of IoT with ML enables predictive maintenance, identifying equipment issues before they lead to overheating or sparks, thus addressing the heat component of the fire tetrahedron. By automating responses, such as triggering sprinklers or shutting down equipment, these technologies work together to interrupt the chemical chain reaction, ensuring rapid fire suppression and minimizing damage.

Conclusion

The fire tetrahedron offers a complete understanding of fire dynamics by including the critical fourth component: the chemical chain reaction. This model not only helps in identifying how fires start but also how they sustain and spread. By applying the fire tetrahedron in fire safety education, firefighting strategies, and industrial safety programs, individuals and organizations can more effectively prevent and control fires, enhancing safety and saving lives.

Keep yourself safe at all times. Contact us to learn how.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Fire Protection and Safety, with a Podcast. Click on the latest Podcast Links: Fire Protection Through Thermal Imaging in Powder and Bulk Handling Industries

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.