Updated October 7, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is a Class D Fire?

Class D fires, characterized by their involvement of combustible metals, pose unique challenges and require specialized extinguishing methods, a specialized fire extinguisher, and specialized fire safety to control and suppress effectively. This comprehensive article explores Class D fires, their characteristics, common causes, and various Class D fire extinguishing techniques tailored for these specific types of fires. The National Fire Protection Association, NFPA, created the NFPA 10 Standard for Portable Fire Extinguishers. NFPA 10 provides requirements to ensure that a portable Class D fire extinguisher will work as intended to provide a first line of defense and fire safety, against burning metals and combustible metal fires.

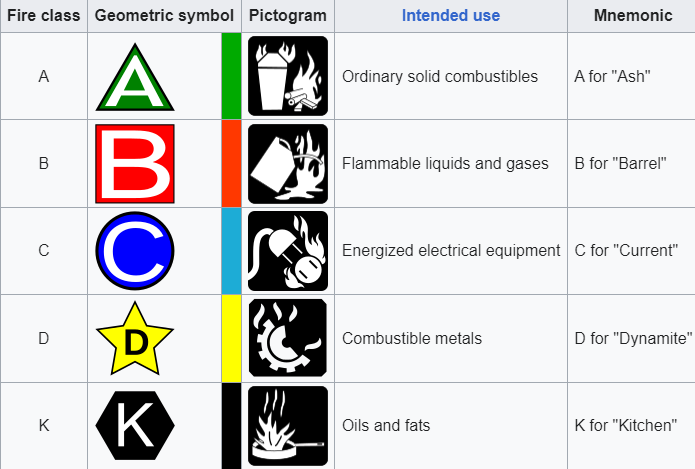

According to Wikipedia, a fire class is a system of categorizing fire on the type of material and fuel for combustion. Class letters are often assigned to the different types of fire, but these differ between territories; there are separate standards for the United States, Europe, and Australia. The fire class is used to determine the types of extinguishing agents that can be used for that category.

Understanding Class D Fires

Class D fires involve combustible metals that ignite and burn when exposed to air or water, requiring a Class D fire extinguisher. Unlike conventional fires involving organic materials, flammable liquids, or gases, Class D fires are types of fires fueled by combustible metals such as magnesium, titanium, sodium, zirconium, lithium, and potassium. These metals are highly reactive and can burn at extremely high temperatures, often exceeding 1000°C (1832°F), requiring specialized fire safety for the extreme heat, and a specialized fire extinguisher.

Characteristics of a Class D Fire:

- High Temperature: Combustible metals burn at very high temperatures due to their chemical properties and heat release during combustion.

- Reactivity: Metals like sodium and potassium react violently with water and can release hydrogen gas, which can further fuel the fire or lead to explosions.

- Unique Extinguishing Challenges: Traditional firefighting methods such as water or carbon dioxide can exacerbate Class D fires by causing splashing or chemical reactions.

Common Materials Causing Class D Fires

A specific concern is the diversity of metals used in the metalworking industry. Different metals and materials have varying properties and may pose a higher risk of combustion or explosion than others.

Magnesium is lightweight, strong, and commonly used in the automotive and aerospace industries. However, it is highly flammable and burns at extremely high temperatures. When ignited, magnesium produces intense heat and bright white light, making it dangerous and difficult to extinguish with water or standard extinguishers. Proper storage and handling are essential to prevent magnesium fires.

Titanium is valued for its strength, corrosion resistance, and lightweight. It is widely used in the medical, aerospace, and military industries. However, titanium can ignite and sustain a fire at lower temperatures compared to other metals, and once burning, it is difficult to extinguish. Special fire extinguishing agents, such as Class D extinguishers, are necessary for controlling titanium fires.

Zirconium is used in various industries, including nuclear reactors, due to its high melting point and resistance to corrosion. However, zirconium dust and shavings are highly flammable and can ignite easily. Handling zirconium requires strict adherence to safety protocols to prevent accidental fires.

Lithium is increasingly used in batteries for electronics and electric vehicles. While lithium is highly reactive, the metal itself is relatively safe in its pure form. However, according to the National Fire Protection Association, lithium-ion batteries pose a significant fire risk if damaged or improperly handled, leading to intense and hard-to-control fires. In addition, OSHA provides recommendations for preventing fire and Explosion Injuries from Small and Wearable Lithium Battery Powered Devices

Both sodium and potassium are metal alkalis that react violently with water, producing hydrogen gas and heat, which can lead to explosions and fires. Fires involving sodium or potassium require specific dry chemical extinguishers to prevent further reactions. Use sand or Class D fire extinguishers on alkali fires. Do not use CO2 extinguishers.

Common Causes of Class D Fires

Class D fires typically occur in industrial settings where these metals are processed, stored, or used. Industries such as manufacturing (especially aerospace and automotive sectors), laboratories, and certain chemical plants are prone to Class D fire risks, metal dust causing a metal fire, and electrical fires. Common causes include:

- Accidental ignition during metal machining or welding processes

- Improper handling or storage of combustible metals and flammable liquids

- Sparks or hot surfaces coming into contact with reactive metals

Extinguishing Methods for Class D Fires

Due to the unique characteristics of Class D fires, specialized extinguishing methods, fire extinguisher training, and fire safety are essential to effectively control and suppress combustible metal fires. Here are some commonly used techniques:

Dry Powder Extinguishers: Powder extinguishers and dry powder extinguishing agents are the primary choice for combating Class D fires. These extinguishers contain specially formulated powders as an extinguishing agent, that work by:

- Smothering the Fire: The powder blankets the burning metal, cutting off its oxygen supply and preventing further combustion.

- Cooling Effect: Some powders also absorb heat from the fire, helping to lower the temperature of the metal, and extreme heat.

Common powder agents include sodium chloride (NaCl), sodium carbonate (Na₂CO₃), and graphite powder. These agents are chosen based on their effectiveness in smothering and cooling different types of combustible metals and these types of fires.

Sand or Dry Powder Application: In environments where Class D extinguishers may not be readily available, sand or a powder such as sodium chloride can be used as an emergency measure. The principles are similar to those of powder extinguishers:

- Covering the Fire: Pouring sand or powder directly onto the fire helps to smother it and prevent the spread of flames.

- Absorbing Heat: Sand and certain powders can absorb heat from the burning metal, aiding in the extinguishing process.

Specialized Fire Blankets

Fire blankets made from fire-resistant materials can be used to extinguish small Class D fires by smothering them and preventing oxygen from reaching the burning metal. Fire blankets are particularly useful in laboratories or workstations where combustible metals are handled.

Class D Fire Suppression Systems

For larger or high-risk environments, such as industrial facilities or research laboratories, specialized Class D fire suppression systems are recommended. These systems are designed to automatically detect and suppress fires using:

- Dry Powder Agents: Similar to portable extinguishers, these systems dispense powder agents (e.g., sodium chloride) to extinguish the fire.

- Automatic Activation: Activation can be triggered by heat sensors or flame detectors, ensuring rapid response to mitigate fire damage.

Class D Fire Safety Considerations and Best Practices

To effectively manage Class D fire risks, it is essential to implement proactive measures and adhere to safety guidelines:

Personnel training and awareness: Employees should receive training on recognizing Class D fire hazards, understanding the appropriate response procedures, and safely using extinguishing equipment.

Emergency Procedures: Establish clear emergency response plans that include evacuation routes, assembly points, and procedures for alerting emergency services.

Preventive Maintenance and Storage

- Storage Guidelines: Store combustible metals in designated areas that are well-ventilated and away from incompatible materials.

- Equipment Maintenance: Regularly inspect and maintain fire suppression systems and extinguishing equipment to ensure they are operational and effective.

Regulatory Compliance

Adhere to local regulations and standards regarding the handling, storage, and extinguishing of combustible metals. Consult with fire safety experts to ensure compliance with relevant codes and guidelines. The NFPA 484, Standard for Combustible Metals, was developed in response to fires where fire suppression water was used inappropriately, often with disastrous results.

The standard includes widely accepted safety requirements for any metal that meets its definition of a combustible metal, including alkali metals, aluminum, hafnium, magnesium, niobium, tantalum, titanium, and zirconium. NFPA 484, Standard for Combustible Metals, addresses the production, processing, finishing, handling, storage, use, and recycling of all metals and alloys that are in a form capable of combustion or explosion.

According to OSHA, fixed extinguishing systems throughout the workplace are among the most reliable firefighting tools. These systems detect fires, sound an alarm, and apply water or another extinguishing agent to the fire.

Conclusion

There are several fire classes, and Class D fires represent a unique fire hazard due to the properties of combustible metals involved, requiring a Class D fire extinguisher, or a dry powder extinguisher, for metal fires. Understanding their characteristics, common causes, and appropriate extinguishing methods is crucial for mitigating metal dust fires, and ensuring workplace safety. By implementing specialized Class D fire extinguisher and extinguishing techniques, training personnel, and maintaining proactive safety measures, industries can effectively manage and reduce the potential impact of Class D fires and metal fires on personnel, property, and operations.

About Dust Safety Science

For more from Dr. Chris Cloney on Fire Extinguishing Systems, visit this Podcast: Understanding Spark Detection, Arresting, Aborting, and Extinguishing Systems

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art fire and explosion protection.