Published October 24, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is Effective Dust Management?

In industrial settings, managing dust is not just a matter of cleanliness, it is a critical safety measure. Dust management is crucial in preventing hazardous incidents, including explosions and respiratory health issues. In Industries handling combustible dust, the stakes are even higher, as poor management can lead to catastrophic explosions. In 2023 alone, there were over 150 dust-related incidents in industrial environments, resulting in injuries and costly damages. This statistic underscores the growing importance of proactive dust management strategies.

Effective dust management requires a combination of engineering solutions, operational protocols, and employee awareness. This article will cover the top strategies for industrial safety, explaining how these methods can help mitigate hazards and ensure a safer work environment.

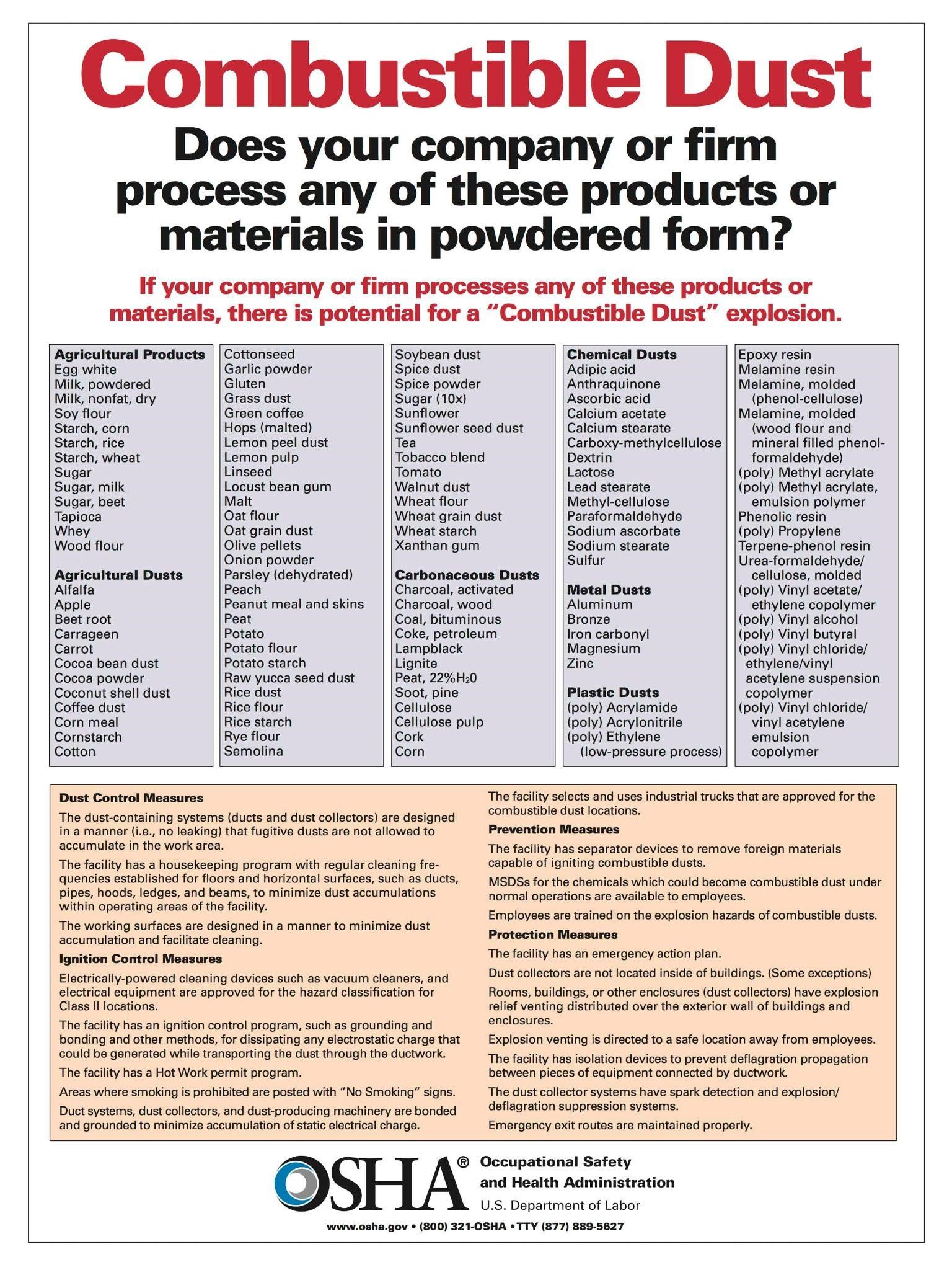

Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing.

Combustible dust may seem like an innocuous byproduct of industrial processes, but in certain conditions, it can pose severe risks, including dust explosions and fires. Understanding the formation, identification, and risks associated with combustible dust clouds is crucial for safety management in industries such as manufacturing, woodworking, and metalworking.

A combustible dust cloud consists of fine particles suspended in the air, when exposed to an ignition source, can lead to a fire or explosion. Combustible dust is created from a variety of materials, including organic substances like wood, and grain, as well as metals, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area.

Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as cutting, grinding, or transporting materials. These clouds can accumulate over time in hidden areas such as rafters, ductwork, or equipment, leading to dangerous buildup.

Why a Dust Collection System is the Foundation of Effective Dust Management

The first line of defense against harmful dust accumulation in industrial settings is a robust dust collection system. These systems help capture and remove dust before it has a chance to accumulate, reducing the risk of respiratory hazards and explosions. Dust collection systems come in various forms, including baghouses, cartridge filters, and cyclones, each designed to manage different types of dust.

- Baghouses: Ideal for handling large volumes of dust, especially in industries like mining and metalworking.

- Cartridge filters: These filters efficiently filter fine dust particles, in pharmaceutical and woodworking industries.

- Cyclones: These are effective for separating larger particles from air streams, typically used as pre-filters in various industries.

Industrial dust collection systems offer several benefits:

- Improved air quality: By filtering out airborne dust, these systems enhance workplace air quality, reducing respiratory issues.

- Fire and explosion prevention: Removing combustible dust reduces the risk of ignition, a significant hazard in industries like agriculture, woodworking, and chemical processing.

- Regulatory compliance: Many industries are required by OSHA and NFPA standards to have dust collection systems in place.

Pro Tip: When choosing a dust collection system, ensure it matches the type of dust generated in your facility. For example, wood dust and metal dust have different filtration needs, and selecting the right system will optimize efficiency and safety.

Conducting Routine Dust Hazard Analysis for Effective Dust Management

Dust Hazard Analysis (DHA) is a systematic approach to identifying and addressing dust-related risks in an industrial setting. A Dust Hazard Analysis involves evaluating the types of dust present, the potential ignition sources, and the likelihood of a dust explosion. Regular DHA is essential for keeping facilities compliant with NFPA 652 and other regulatory standards.

DHA helps facilities:

- Identify potential hazards: Understanding where dust accumulates and how it interacts with heat sources can help prevent incidents.

- Mitigate risks: Once hazards are identified, facilities can implement control measures such as improved ventilation or dust collection upgrades.

- Ensure compliance: OSHA and NFPA require industries dealing with combustible dust to perform regular DHAs.

Pro Tip: Schedule DHAs at least once a year or whenever there are significant changes to your process or facility layout. Pay close attention to areas where dust can accumulate, such as corners, overhead beams, and around equipment.

Keeping Dust Under Control with Proper Housekeeping Strategies

Good housekeeping is one of the simplest yet most effective ways to prevent dust from accumulating to dangerous levels. A proper cleaning regimen ensures that dust doesn’t collect in areas that are hard to see or reach, which can become potential fire hazards.

Best Cleaning Practices for Dust Management:

- Vacuuming: Always opt for Combustible Dust Rated vacuums equipped with HEPA filters, as they prevent dust from being reintroduced into the air.

- Avoid sweeping and Compressed Air: Sweeping and compressed air can disperse dust into the air, increasing inhalation risks and the potential for an explosion.

- Dust Control Fans: HazLoc and UL Certified Dust Control Fans, use high-velocity airflow to create an air curtain and air barrier, preventing them from settling and accumulating.

- Pro Tip: Establish a routine cleaning schedule, focusing on high-traffic areas and equipment prone to dust accumulation. Use tools designed specifically for industrial settings, such as anti-static vacuums for combustible dust.

The Role of Transfer Chutes, Rock Boxes, Liners, and Skirting in Dust Management for Conveyor Belts

In industrial operations where conveyor belts are used to transport materials, dust generation can pose significant hazards. Implementing the National Institute for Occupational Safety and Health (NIOSH), and Centers for Disease Control and Prevention (CDC) recommendations for transfer chutes, rock boxes, liners, and skirting can significantly reduce dust emissions and improve overall dust management. Each of these components plays a specific role in controlling dust at critical points along the conveyor system:

- Transfer chutes: These guide the material from one conveyor to another, reducing the free fall of materials and minimizing dust generation during the transfer process.

- Rock boxes: Installed at transfer points, rock boxes reduce material impact and prevent excessive dust release by encouraging a controlled flow of materials.

- Liners: These are applied inside transfer chutes or rock boxes to reduce wear and tear, as well as minimize dust production by reducing material impact and friction.

- Skirting: Installed along the sides of conveyor belts, skirting seals the area between the belt and the conveyor, preventing dust from escaping during material transportation.

Together, these elements help contain dust and create a safer, cleaner working environment while also reducing the need for frequent cleaning and maintenance.

Maintaining Safe Air Quality Through Effective Ventilation

Proper ventilation is essential for maintaining air quality and managing dust in industrial environments. Ventilation systems work in tandem with dust collection systems to ensure airborne dust is effectively captured and removed from the workspace.

Ventilation Solutions for Dust Management:

- Dilution ventilation: Introduces fresh air into the workspace to dilute and reduce the concentration of dust particles in the air.

- Local exhaust ventilation (LEV): Captures dust at the source, preventing it from becoming airborne and spreading throughout the facility.

Well-designed ventilation systems help control dust at its point of origin and prevent it from migrating to other areas where it could accumulate or ignite.

Pro Tip: Regularly inspect ventilation systems to ensure they are functioning properly. Inadequate airflow can lead to dust buildup in ductwork, increasing fire risks.

Why Employee Education is Key to Preventing Dust-Related Incidents

One of the most effective strategies for dust management is ensuring that employees are well-trained on the hazards associated with combustible dust and the correct procedures for minimizing risks. Workers on the floor are often the first line of defense against dust-related hazards.

How Employee Training Supports Dust Management Goals:

- Identifying hazardous dust: Employees should understand what types of dust are combustible and how they behave.

- Safe handling practices: Workers should be trained on safe work practices, such as minimizing dust creation during production.

- Emergency procedures: In the event of a dust explosion or fire, employees need to know the proper evacuation and response protocols.

Pro Tip: Use interactive training methods, such as simulations or hands-on demonstrations, to reinforce important safety practices and ensure compliance with dust management procedures.

Installing Explosion Protection Equipment to Prevent Dust Explosions

Explosion protection systems are critical in facilities handling combustible dust. These systems, which include explosion venting, suppression, and isolation systems, are designed to mitigate the effects of an explosion should it occur.

The Role of Explosion Protection Systems in Dust Management:

- Explosion venting: Relieves pressure from an explosion by directing it safely outside the facility.

- Suppression systems: Detect an explosion in its early stages and suppress it by releasing an extinguishing agent.

- Isolation systems: Prevent an explosion from spreading to other parts of the facility by isolating the affected area.

Pro Tip: Work with explosion protection experts to evaluate which system is best suited for your facility. Consider factors such as the type of dust and the facility’s layout when choosing between venting, suppression, or isolation.

Meeting Regulatory Standards for Dust Management and Safety

Complying with OSHA and NFPA standards is not only a legal obligation but also a key component of effective dust management. Both organizations provide detailed guidelines for managing combustible dust and preventing accidents.

How Compliance with Dust Management Regulations Reduces Risks:

- OSHA’s Combustible Dust National Emphasis Program (NEP): The Occupational Safety and Health Administration, (OSHA), provides Revised Combustible Dust National Emphasis Program guidelines to help industries manage combustible dust hazards.

- FPA 652: Standard on the Fundamentals of Combustible Dust: Provides a general framework for managing combustible dust hazards in various industries.

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions: Focuses on the design, construction, and operation of facilities handling combustible dust.

Maintaining compliance with these standards helps facilities avoid fines, legal liabilities, and, most importantly, reduces the risk of dust-related accidents.

Pro Tip: Stay up-to-date with regulatory changes by regularly reviewing OSHA and NFPA publications. Consider appointing a compliance officer to ensure your facility meets all dust management regulations.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), for Dust Management

Recent advancements in Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) are significantly transforming fire detection and prevention, especially in industries managing combustible dust. AI-driven systems can now analyze massive datasets from various sensors in real-time, allowing for predictive maintenance and early detection of potential fire hazards. These intelligent systems can assess conditions such as temperature spikes, unusual airflow patterns, and dust accumulation, identifying areas of concern long before they reach critical levels. By using AI algorithms, industries can implement automated responses, such as activating dust suppression systems or shutting down equipment, preventing fires from igniting.

IoT and Machine Learning have further enhanced fire prevention by enabling connected systems that continuously monitor equipment and environmental conditions. IoT sensors installed on machinery and conveyor belts can collect real-time data on dust levels, airflow, and temperature, sending this data to cloud-based platforms. ML algorithms can analyze this data to identify patterns, predict failures, and recommend proactive interventions. These technologies allow facilities to automate dust control and fire suppression efforts with greater precision, minimizing human error and reducing the chances of catastrophic dust explosions. By integrating AI, IoT, and ML, dust monitors, dust sampling, and thermography, industries can optimize their dust management strategies and achieve smarter, more reliable fire prevention measures.

Conclusion

Effective dust management is a critical aspect of industrial safety, and implementing the right strategies can dramatically reduce the risks associated with combustible dust. From installing a dust collection system to conducting regular Dust Hazard Analyses and ensuring employee training, each of the strategies discussed plays a vital role in creating a safer workplace.

By assessing your current practices and integrating these strategies, you can safeguard your facility against dust-related incidents. As dust management regulations evolve, staying compliant will further ensure a safe and efficient operation.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Combustible Dust Management, with a Podcast. Click on the latest Podcast Links: Use of 3D Scanning in Processing Facilities

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.