Updated February 17, 2025 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A Dust Hazard Analysis is a critical step in evaluating the combustible dust fire, flash fire and explosion hazards at your facility. Read on to learn what a DHA is, why it is needed and the 10 steps to make sure it is effective against combustible dust when completed at your facility.

Key Takeaways:

- In a Dust Hazard Analysis each piece of equipment and building compartment is evaluated for fire, flash fire and combustible dust explosion hazards.

- Learn important terms and definitions related to Dust Hazard Analysis.

- There are 10 steps needed to complete an effective Dust Hazard Analysis process.

- From training on dust explosions to consulting, engineering support, compliance, and software, there are many tools, companies, and professionals that can support you on your team’s dust hazard analysis process and procedures.

Table of Contents:

- What is a Dust Hazard Analysis?

- Important Definitions and Terms

- Steps to Complete a Dust Hazard Analysis

- Offering Services for Dust Hazard Analysis

- Conclusion

- Frequently Asked Questions

What is a Dust Hazard Analysis?

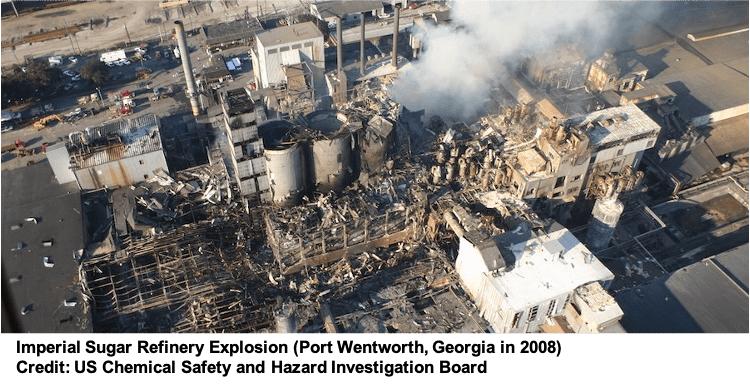

A Dust Hazard Analysis (DHA) is a systematic review to identify and evaluate the potential flash fires, or combustible dust explosion hazards, such as a dust cloud associated with the presence of one or more combustible particulate solids in a process or facility, NFPA 652-19. While NFPA standards are not enforceable, the Occupational Health and Safety Administration (OSHA) relies on these standards when conducting enforcement activities under the Combustible Dust National Emphasis Program.

The goal of a combustible Dust Hazard Analysis is identifying and mitigating combustible dust hazards such as combustible dust fires, and combustible dust explosion hazards that pose a risk to people and property. Each hazard analysis process or area reviewed will fall into one of five categories:

- Not a Hazard: In instances where the Dust Hazard Analysis determines that there is no hazard present, no further investigation or precautionary measures are necessary. This classification of “Not a Hazard” provides peace of mind, indicating that the process or area under scrutiny is safe from fire, flash-fire, combustible dust explosions, or explosion risks.

- Could be Hazardous: Additional testing and information are required to determine whether a hazardous condition exists or not. If the analysis identifies the potential for hazards but lacks sufficient information or testing data to conclusively confirm their existence, additional investigations and data collection become imperative. This stage serves as a critical step towards ensuring safety by striving to either confirm or rule out combustible dust hazards, leading to combustible dust explosions.

- Fire Hazard: Within the scope of a DHA, the recognition of a fire hazard signifies the potential for combustible materials to ignite and sustain a fire. This broader category encompasses various scenarios where the ignition of flammable substances poses a threat to safety and property.

- Flash Fire Hazard: Expanding further, a DHA may reveal the presence of fire hazards. Flash fires are rapid, intense fires that occur when flammable gasses, vapors, or dust particles ignite suddenly. Identifying fire hazards is crucial for implementing preventive measures and ensuring the safety of personnel and facilities.

- Explosion Hazard: Among the most severe outcomes, a DHA can uncover the risk of combustible dust hazards and combustible dust explosions, from combustible particulate solids forming a dust cloud. Dust explosions result from the rapid release of energy and can have devastating consequences. Identifying explosion hazards and dust explosion prevention in a Dust Hazard Analysis, DHA, is paramount to establishing comprehensive safety measures, including the containment of explosive potential and the protection of individuals and assets.

Important Definitions and Terms

Below is a list of DHA-specific terms that are relevant to understanding and performing a DHA at your facility.

- Hazard: a physical or chemical characteristic that can potentially cause injury or damage.

- Scenario: description of an unexpected event or incident sequence that causes loss, as well as how well any safeguards performed.

- Consequence: The negative outcome of an event, typically measured in terms of injuries, fatalities, property loss, business loss, and any environmental impacts.

- Likelihood: The probability or frequency of an event

- Risk: The chances that an incident could injure people, destroy property, and cause environmental damage.

- Safeguard: Any protective device, system, or action that either interrupts further events after the inciting incident occurs or mitigates the consequences.

Steps to Complete a Dust Hazard Analysis

There are 10 steps recommended to implement a Dust Hazard Analysis.

Step 1: Determine If Combustible Dust Is Present: This is completed using go/no-go screening tests, with combustible dust testing, or flammability or explosion severity testing.

Step 2: Identify Which Standards Apply: This includes NFPA standards as well as the Occupational Health and Safety Administration (OSHA) regulations, and other local, state, regional, and municipality requirements applicable to the facility.

Step 3: Assemble the DHA Team: NFPA 652 recommends that a DHA be completed by a team, but requires that team to be led by a qualified person. Ideally, the team should consist of experienced individuals from Plant Management, Environmental, Health and Safety specialists, plant engineering, Operations, and Maintenance.

Step 4: Collect the Required Documentation: Includes process flow diagrams, piping and instrumentation diagrams of the process, emergency response plans, housekeeping practices, and more.

Step 5: Identify Credible Fire and Explosion Scenarios: Review each piece of equipment, dust collector systems, processing area, and building compartment for combustible dust fires, combustible dust hazards, dust cloud formation, and dust explosion hazards.

Step 6: Review existing safeguards: Evaluate existing safeguards against the standards identified in Step 2.

Step 7: Propose Additional Safeguards: Based on a gap analysis, identify areas where additional safeguards are needed, to prevent combustible dust hazards, and dust explosions.

Step 8: Determine Proposed Change in Scenario Consequence and Likelihood: Complete a hazard assessment to determine which risk reduction options should be used and in which order they should be applied.

Step 9: Document Overall Recommendations: Write the DHA report to document the overall methods used, findings, and recommendations from the Dust Hazard Analysis.

Step 10: Implement Recommendations: This is the final step in the process which requires that recommendations be implemented on time, to reduce the risk of a combustible dust fire, dust cloud formation, or dust explosions at the facility, from combustible particulate solids and possible combustible dust testing.

Offering Services for Dust Hazard Analysis

When it comes to Dust Hazard Analysis (DHA), businesses can benefit from a range of specialized services and expertise, from dust explosion prevention. These Dust Hazard Analysis services are provided by professionals and organizations dedicated to helping companies identify, assess, and mitigate combustible dust hazards such as dust cloud formation, and combustible dust incidents effectively. Selecting the right combination of these dust explosion prevention services depends on the unique needs and circumstances of each business. Engaging with qualified professionals and organizations specializing in DHA is essential for achieving comprehensive and effective dust hazard management, ultimately ensuring workplace safety and regulatory compliance. Below are some essential services offered by a DHA.

- DHA Consultation: Experienced consultants can provide valuable guidance throughout the DHA process. They assist businesses in understanding the complexities of combustible dust hazards, regulatory requirements, and best practices. Consultants work closely with organizations to develop customized DHA plans and strategies tailored to their specific needs, to have safe operating ranges and proper safeguards for facilities.

- DHA Workshops and Training: DHA workshops and training programs are designed to educate employees and safety professionals on the fundamentals of dust hazard analysis DHA. These programs cover hazard recognition, risk assessment techniques, and the implementation of control measures. Training ensures that personnel are well-equipped to actively participate in the DHA process, and where combustible dust poses a greater risk.

- DHA Audits and Assessments: DHA audits involve comprehensive evaluations of a facility’s dust hazard management practices. Experienced auditors assess existing processes, identify areas of improvement, with specific combustible dust hazards and recommend necessary changes. These audits help businesses enhance their safety measures and achieve compliance with regulatory requirements.

- Engineering and Design Services: Engineering firms specializing in dust hazard management offer services related to the design and installation of dust collection systems, explosion protection measures, and ventilation solutions. They ensure that facilities are equipped with the right engineering controls to mitigate dust hazards effectively.

- Combustible Dust Testing and Analysis: Laboratories and testing services can analyze dust samples to determine their combustibility and health-related properties. This critical information aids in hazard assessment and helps businesses select appropriate control measures and preventive strategies, and to have safe operating ranges and proper safeguards for facilities.

- Emergency Response Planning: Specialized consultants can assist in developing robust emergency response plans specific to dust-related incidents. These plans outline procedures for handling emergencies, protecting personnel, and minimizing damage in the event of a dust hazard incident.

- Documentation and Compliance Support: Navigating the regulatory landscape can be complex. Service providers offer support in documenting DHA processes, maintaining records, and ensuring ongoing compliance with relevant regulations and standards, to existing hazard management measures.

- Risk Assessment Software: Advanced software solutions are available to streamline the risk assessment portion of dust hazard analysis DHA. These tools assist in specific combustible dust hazards, hazard identification, consequence analysis, and the evaluation of risk mitigation strategies.

Conclusion

In this article covering Dust Hazard Analysis (DHA), we have delved into the critical aspects of identifying, assessing, and mitigating the often invisible threats posed by combustible particulate solids, and health-related dusts, and combustible dust incidents in industrial settings. Key points covered include the definition of DHA, the types of combustible dusts and hazards, dust cloud formation, the Dust Hazard Analysis DHA process, services available, and dust explosion prevention. Increasing existing hazard management measures and best practices, to have safe operating ranges and proper safeguards in facilities will lead to the prevention of dust explosions.

The importance of DHA cannot be overstated. Combustible dust poses a significant yet often overlooked hazard. A DHA is not merely a regulatory requirement but a proactive approach, and systematic review to safeguarding the well-being of employees, protecting valuable assets, and ensuring the longevity of business operations. Combustible dust hazards can have dire consequences if left unaddressed. A DHA is the crucial tool that empowers organizations to identify these combustible dusts and hazards, assess their risks, and implement effective control measures.

Frequently Asked Questions (FAQ)

Why is a Dust Hazard Analysis important?

- Answer: Conducting a DHA is essential for ensuring workplace safety, complying with regulations, and preventing catastrophic events caused by combustible dust.

- Answer: Conducting a DHA is essential for ensuring workplace safety, complying with regulations, and preventing catastrophic events caused by combustible dust.

Which industries require a Dust Hazard Analysis?

- Answer: Industries such as agriculture, chemical manufacturing, food processing, metalworking, pharmaceuticals, and woodworking, where combustible dust is present, should conduct a DHA.

What are the steps involved in conducting a DHA?

- Answer: The DHA process typically includes determining if combustible dust is present, identifying applicable standards, assembling a qualified team, conducting a thorough analysis, and implementing necessary safeguards.

- Answer: The DHA process typically includes determining if combustible dust is present, identifying applicable standards, assembling a qualified team, conducting a thorough analysis, and implementing necessary safeguards.

How often should a Dust Hazard Analysis be conducted?

- Answer: A DHA should be conducted for all new installations or expansions and reviewed periodically, typically every five years, even if no changes have been made, to ensure ongoing compliance and safety.

- Answer: A DHA should be conducted for all new installations or expansions and reviewed periodically, typically every five years, even if no changes have been made, to ensure ongoing compliance and safety.

What standards govern Dust Hazard Analysis?

- Answer: The National Fire Protection Association (NFPA) standards, particularly NFPA 652, provide guidelines for conducting DHAs to manage combustible dust hazards.

Who is qualified to perform a Dust Hazard Analysis?

- Answer: A DHA should be led by a qualified person with expertise in combustible dust hazards, often involving a team that includes safety professionals, engineers, and facility managers.

What are the consequences of not conducting a DHA?

- Answer: Failure to perform a DHA can lead to non-compliance with safety regulations, increased risk of dust-related fires or explosions, potential legal liabilities, and harm to personnel and property.

How does a DHA differ from a Process Hazard Analysis (PHA)?

- Answer: While both analyses assess hazards in industrial processes, a DHA specifically focuses on combustible dust hazards, whereas a PHA addresses a broader range of process-related hazards.

What measures can be implemented after a DHA?

- Answer: Post-DHA measures may include improving dust collection systems, implementing housekeeping protocols, controlling ignition sources, and training personnel on dust hazard awareness.

About Dust Safety Science

For more from Dr. Chris Cloney on Dust Hazard Analysis DHA, visit these podcast episodes: Dust Hazard Analysis Requirements for Owners and Operators in NFPA 652 and Dust Hazard Analysis and Explosion Prevention and Dust Hazard Analysis & Explosion Prevention With Dr. Ashok Dastidar Podcast

Resources:

Visit: Dust Safety Science’s Training Page

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.