Published July 31, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Dust Control Challenges in the Mining Industry

Mining activities, including drilling, blasting, crushing, and transporting materials, produce various types of dust. These dust particles, often fine and respirable, can lead to severe health issues such as silicosis, lung cancer, coal workers’ pneumoconiosis (black lung disease), and other respiratory conditions when inhaled by workers. Additionally, dust emissions can contaminate nearby water sources, soil, and air, posing broader environmental risks.

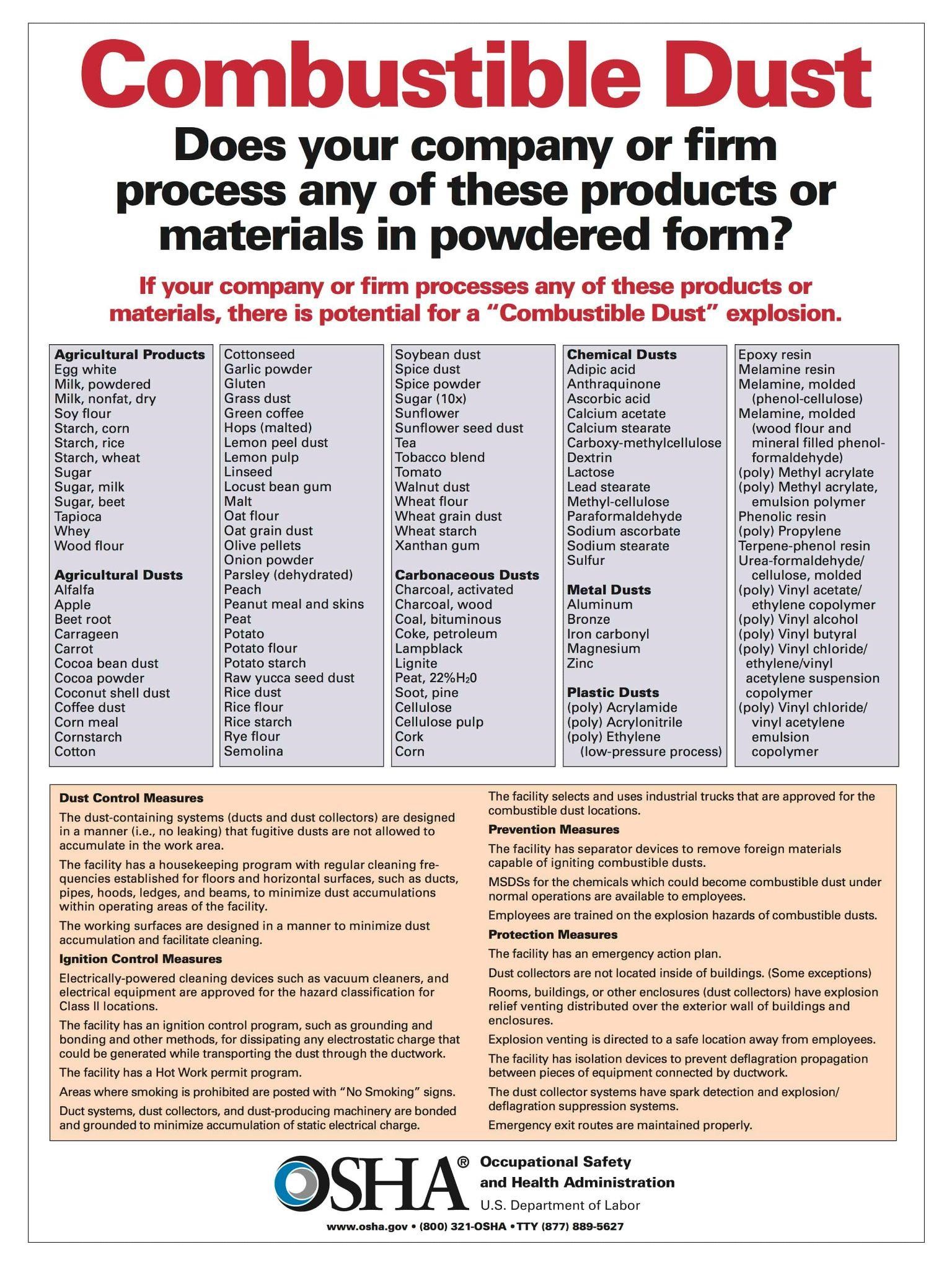

The Occupational Safety and Health Administration, (OSHA), identifies Coal and Biomass as Combustible Dust. Fine dust particulates generated during various stages of coal, biomass, and power generation processing, such as mining, pulverizing, and crushing, constitute the primary source of combustible dust in these facilities. From the pulverized coal used in power plants to the fine particle size generated during biomass combustion, numerous materials pose inherent risks of combustion and explosion when dispersed in the air at certain concentrations. Coal dust is a fugitive combustible dust, a dust that is both a pollutant and combustible when dispersed into the air.

Effective dust control is paramount not only for protecting the health and safety of miners but also for ensuring compliance with stringent environmental regulations. The mining industry faces the dual challenge of maintaining operational efficiency while minimizing the negative impacts of dust emissions.

Types of Dust Generated in Mining Operations and Their Sources

Mining operations generate different types of dust depending on the activities and materials involved. The primary types include:

- Respirable Dust: Fine particles that can be inhaled into the lungs, often containing silica.

- Total Suspended Particulates (TSP): Larger dust particles that settle out of the air more quickly.

- Fugitive Dust: Dust that escapes from operations and becomes airborne, contributing to air pollution.

- Combustible Dust: Coal is a combustible black or brownish-black sedimentary rock used primarily as fuel. It is found in coal beds or coal seams. Sulfide minerals can oxidize and generate heat, leading to spontaneous combustion.

- Rare Earth Elements (REEs): Rare earth elements include minerals like neodymium, cerium, and lanthanum, which are crucial for modern technology such as smartphones, electric vehicles, and wind turbines. Uranium is a radioactive metal used primarily as fuel in nuclear power plants.

Common sources of mining dust include drilling, blasting, crushing, conveyor belts, and transportation of materials. These processes lead to dust clouds and dust resuspenstion, that can cause dust explosions. Mining and processing rare earth metals generate dust that can be toxic if inhaled, leading to respiratory problems and long-term health issues. The extraction of rare earth metals often results in radioactive waste that can contaminate soil and water.

Regulatory Standards for Dust Emissions in the Mining Sector

Regulatory bodies have established standards to limit dust emissions in mining. These standards vary by region but generally include limits on airborne particulate matter, requirements for dust control measures, and regular monitoring and reporting. Compliance with these regulations is crucial for mining companies to avoid penalties and ensure safe operations.

The Mine Safety and Health Administration (MSHA) regulates airborne dust standards for the metal/nonmetal mining industry in the United States. The Federal Mine Safety and Health Act of 1977 defines these standards, which are based on the 1973 American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values formula. The formula is 10 mg/m3 divided by the percentage of quartz plus 2. This is expressed as the concentration of respirable dust for a full shift or an 8-hour equivalent time-weighted average (TWA).

The U.S. Environmental Protection Agency, provides Fugitive Dust Control Measures and Best Practices. According to the U.S. EPA, the term “fugitive dust”, as used in this document, refers to particulate matter that enters the atmosphere without first passing through a stack or duct designed to direct or control its flow. Fugitive dust has been linked to various respiratory issues including aggravated asthma, chronic bronchitis, emphysema, and chronic obstructive pulmonary disease.

Historical Incidents Involving Mining and Dust Control

According to Wikipedia, The worst mining accidents in history have been caused by coal dust explosions, such as the disaster at Senghenydd in South Wales in 1913 in which 439 miners died, the Courrières mine disaster in Northern France which killed 1,099 miners in 1906, the Luisenthal Mine disaster in Germany, which claimed 299 lives in 1962, and the worst: the explosion at Benxihu Colliery, China, which killed 1,549 in 1942. Additionally, more recent coal dust and coal mining explosions and incidents have occured around the world.

Core Strategies for Mining Dust Control

Effective dust control in mining involves a combination of strategies tailored to specific operations and environments. The primary strategies include:

- Water Spray Systems: Utilizing water to suppress dust at the source.

- Dust Suppression Chemicals: Applying chemicals to bind dust particles and prevent them from becoming airborne.

- Advanced Technologies: Implementing automated and remote-controlled systems for efficient dust management.

- Operational Practices: Adopting best practices in material handling and surface management to minimize dust generation.

The Role of Water Spray Systems and Their Application in Mining Sites

Water spray systems are one of the most common and effective methods for controlling dust in mining. These systems use water to wet the dust particles, preventing them from becoming airborne. Water can be applied through various means, including:

- High-Pressure Mist Systems: Generating fine water mist to capture dust particles.

- Wet Drilling Techniques: Using water in drilling operations to reduce dust at the source.

- Road Sprinklers: Keeping haul roads moist to minimize dust from vehicle traffic.

Dust Suppression Chemicals: Types, Benefits, and Application Methods

Dust suppression chemicals are used to enhance the effectiveness of water in controlling dust. These chemicals, such as surfactants and binders, help to stabilize dust particles and reduce the frequency of water applications. The benefits include:

- Increased Dust Control Efficiency: Chemicals can provide longer-lasting dust suppression.

- Reduced Water Usage: Less water is needed when chemicals are used.

- Improved Environmental Compliance: Effective dust control helps meet regulatory standards.

Application methods for dust suppression chemicals include spraying, fogging, and adding to water trucks.

Advanced Technologies in Mining Dust Suppression

The mining industry is continually innovating to improve dust control. New technologies aim to provide more effective and efficient solutions, including:

- Electrostatic Precipitators: Using electrical charges to capture dust particles.

- Vacuum Systems: Removing dust from the air using high-powered vacuums.

- Foam Systems: Applying foam to suppress dust in areas with high dust generation.

Automated Dust Suppression Systems: Features and Advantages

Automated dust suppression systems offer significant advantages over manual methods. These systems can be programmed to operate continuously or at specific times, ensuring consistent dust control. Features include:

- Real-Time Monitoring: Sensors detect dust levels and activate suppression systems as needed.

- Remote Operation: Systems can be controlled and monitored from a distance, reducing the need for onsite personnel.

- Efficiency and Cost Savings: Automated systems reduce labor costs and improve overall dust control efficiency.

The Use of Drones and Remote-Controlled Devices for Dust Monitoring and Control

Drones and remote-controlled devices are increasingly being used for dust monitoring and control in mining. These technologies provide several benefits:

- Enhanced Coverage: Drones can access hard-to-reach areas and provide comprehensive dust monitoring.

- Real-Time Data Collection: Immediate data on dust levels allows for quick response and adjustments.

- Improved Safety: Reducing the need for personnel in hazardous areas.

Operational Practices for Dust Reduction

Implementing best practices in mining operations can significantly reduce dust generation. Key practices include:

- Controlled Blasting: Using precise blasting techniques to minimize dust production.

- Optimized Drilling Methods: Utilizing wet drilling and other dust-reducing techniques.

- Enclosed Conveyors: Reducing dust escape from material transport systems.

Material Handling Protocols to Reduce Dust at the Source

Proper material handling protocols are essential for dust control. Strategies include:

- Minimizing Drop Heights: Reducing the height from which materials are dropped to decrease dust generation.

- Using Enclosed Systems: Enclosing conveyors and transfer points to contain dust.

- Regular Maintenance: Keeping equipment in good condition to prevent dust leaks.

Road and Surface Management Strategies for Dust Control

Road and surface management play a crucial role in controlling dust. Effective strategies include:

- Regular Watering: Keeping roads and surfaces moist to prevent dust from becoming airborne.

- Surface Treatments: Applying dust suppressants or stabilizers to road surfaces.

- Traffic Control: Limiting vehicle speeds and optimizing traffic patterns to reduce dust generation.

Personal Protective Equipment (PPE) and Worker Safety

Personal protective equipment (PPE) is essential for protecting workers from dust exposure. Proper use of PPE can significantly reduce the risk of respiratory and other health issues.

Respiratory protection is critical in dusty mining environments. Types of respiratory PPE include:

- Disposable Masks: Suitable for low to moderate dust levels.

- Half-Face Respirators: Providing better protection with replaceable filters.

- Full-Face Respirators: Offering the highest level of protection with full-face coverage.

Guidelines for use include ensuring proper fit, regular maintenance, and training workers on correct usage.

Training and Awareness Programs for Miners on Dust Hazards and Prevention

Training and awareness programs are vital for ensuring workers understand the risks of dust exposure and how to prevent it. Effective programs include:

- Regular Training Sessions: Covering the latest dust control practices and PPE usage.

- Awareness Campaigns: Highlighting the importance of dust control and personal safety.

- Health Monitoring: Regular health checks to identify and address dust-related health issues early.

Dust Monitoring Techniques and Equipment Used in the Mining Industry

Accurate dust monitoring is crucial for effective dust control. Techniques and equipment used in the mining industry include:

- Gravimetric Sampling: Measuring dust concentration by collecting and weighing dust samples.

- Real-Time Monitoring: Using electronic sensors to provide continuous dust level data.

- Personal Dust Monitors: Equipping workers with monitors to track individual dust exposure.

Compliance with Regulatory Standards and the Role of Environmental Monitoring

Compliance with regulatory standards is mandatory for mining operations. Environmental monitoring plays a key role in ensuring compliance by:

- Regular Reporting: Submitting dust level data to regulatory bodies.

- Audits and Inspections: Conducting regular audits to verify compliance with dust control measures.

- Corrective Actions: Implementing corrective measures when dust levels exceed acceptable limits.

Data-Driven Approaches to Dust Management and Control Strategy Adjustments

Data-driven approaches enable mining companies to optimize their dust control strategies. By analyzing dust level data, companies can:

- Identify Trends: Recognize patterns in dust generation and adjust control measures accordingly.

- Improve Efficiency: Implement targeted dust control measures based on data insights.

- Enhance Compliance: Ensure ongoing compliance with regulatory standards through continuous monitoring and adjustment.

Conclusion

Effective dust control is essential for the mining industry to protect worker health, ensure safety, and comply with environmental regulations. Comprehensive strategies, including the use of advanced technologies, best operational practices, and proper PPE, play a critical role in minimizing dust generation and exposure. As dust control technologies and practices continue to evolve, the mining industry must remain proactive in adopting innovative solutions to maintain safe and sustainable operations

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Dust Control in Coal Handing, with a Podcast. Click on the latest Podcast Link: How to Develop a Dust Control Project in a Coal Handling Process

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art fire and explosion protection.