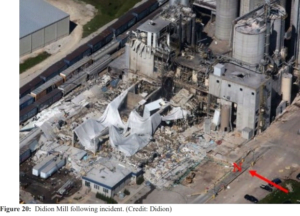

On May 31, 2017, a grain dust explosion ripped through the Didion Milling facility in the community of Cambria, Wisconsin. Didion Milling Inc. since 1972, the milling company operates a corn milling and biofuels facility in Cambria and production facilities in Markesan and Johnson Creek. The tragic combustible dust incident resulted in three fatalities and 13 injuries. Two of the injured later died in hospital bringing the total to five lives lost, and a criminal prosecution against Didion Milling in Cambria, Wisconsin, was conducted by the US Justice Department and the Wisconsin attorney general as a result of the fine grain dust explosions. The Justice Department, the EPA and its law enforcement partners are committed to seeking justice for victims of environmental crime and their families. The company agreed to pay a $1 million fine and $10.25 million to the estates of the five workers who were killed. At least five other Didion employees including a Former Didion Milling Food Safety Superintendent, have pleaded guilty to or been convicted of charges including concealing environmental violations, lying to investigators and falsifying cleaning logs, disregarding worker safety protections.

A subsequent OSHA investigation found that a fire had occurred two days prior to the incident in a fluidized bed dryer and that the company had previous citations from 2011 including missing explosion protection on combustible dust collecting units, and problems with the dust collection system at Didion’s corn mill. In addition, an investigation into Didion Milling grain handling facilities, worker and food safety, air pollution, and environmental protection practices, uncovered criminal violations of environmental laws attributable to both the company and senior officials. Some of the officials and the Didion Milling Vice President pleaded guilty and were sent to Federal Prison. Former Didion Milling environmental manager Joseph Winch previously pleaded guilty to conspiracy to conceal violations from regulators by falsifying compliance certifications and providing falsified logs and false statements to regulators,

On November 11, 2017, the Occupational Safety and Health Administration, OSHA, released their report outlining the citations and penalties to Didion Milling Inc. corn mill, regarding the mill explosion. Review of the citations gives important insight into workplace safety, and combustible dust, with several deficiencies that may have lead to initiation of the explosion incident, as well as the severity of the outcome, including individual corporate managers sent to federal prison. These citations are reviewed in the following article, to assist with workplace safety, corn milling, food safety, grain dust particulate matter, and combustible dust explosions. In addition, a Clean Air Act Violation and fine was imposed on Didion Milling, from a Didion personnel, making false Clean Air Act compliance certifications and the company, pleaded guilty to falsifying its environmental and sanitation logs. The convicted people await sentencing before U.S. District Court Judge James D. Peterson for the Western District of Wisconsin on various charges related to the incident, and the five workers who were killed.

Lastly, a section at the end of the post highlights fundraising campaigns where you can support the Didion Milling victims, families, and community affected by the Didion Milling explosion. If you know of any other campaigns, please leave them in the comments and I will add them to the list.

Summary of Penalties

The Occupational Safety and Health Administration citation report identified two separate citations (Serious and Willful) with a total of 19 items of noncompliance, against Didion Milling. A wilful violation is the most severe and requires that the employer either knowingly failed to comply with legal requirements or acted with plain indifference to employee safety (see definitions here).

For ease of reference, the violations have been further divided into categories including equipment, training, maintenance, housekeeping, workplace safety, and PPE in the following.

Serious Penalties

A summary of the “Serious” violation penalties is given below. Equipment violations included absent fire protection, explosion protection, and noncompliant training and maintenance programs.

- Serious (Equipment): $38,025

- Serious (Training & Maintenance): $25,350

Wilful Penalties

A summary of the “Willful” violation penalties is given as follows. The largest of these penalties are for an inadequate or ineffective housekeeping program which may have increased the overall scale of the devastating explosion.

- Willful (Equipment): $253,498

- Willful (Housekeeping): $760,494

- Willful (Safety Systems): $253,498

- Willful (Personal Protective Equipment): $126,749

- Willful (Maintenance): $380,247

Total

In total, the proposed penalties amounted to $1.8 M. Didion Milling had until January 9, 2018 to contest the penalties and/or provide abatement action. To the authors knowledge, information has not been made public regarding either action to date.

- Total Serious (Citation 1): $63,375

- Total Wilful (Citation 2): $1,774,468

- Total Proposed Penalties: $1,837,861

Didion Milling OSHA Citations

The following sections outline the serious and wilful violations indicated by OSHA, against Didion Milling. Where provided in the report, the equipment, location in the facility, and acceptable protection methods for the violation are provided.

Serious Violations (Equipment)

Citation 1, Items 1, 3, and 5 covered serious violations regarding combustible dust and grain processing equipment. These include absence of automatic fire protection on the fluidized bed dryer, absence of explosion protection on many dust collectors, and absence of an effective means to remove combustible dust ferrous material from grain size reduction equipment.

|

Citation 1/Item 1 Violation: OSH ACT of 1970 Section (5)(a)(1) Description: Indoor fluid bed dryer not equipped with automatic fire protection Equipment: Expander #5 Fluid Bed Dryer (1st Floor, C Mill) Protection Methods: NFPA 61, S:8.3.9.4.3 (dryer fire detection, alarm, and interlocking system) NFPA 61, S:8.3.9.4.4 (dryer suppression and extinguishing systems) Proposed Penalty: $12,675.00 |

|

Citation 1/Item 3 Violation: 29 CFR 1910.272(l)(2) Description: Indoor filter collectors not equipped with explosion suppression system Equipment: a) Kice filter dust collector (3rd floor mezzanine, F Mill) b) Torit dust collector (2nd floor, F Mill) c) Flex-Kleen/Bran dust collector (4th floor, D Mill) d) Bran dust collector (2nd floor, D Mill) e) Pack Line #1 Dust Collector (Packing Room Mezzanine) f) Clean Cor Dust Collector (4th Flor, B Mill) g) BGM Dust Collector (4th Floor, B Mill) h) Expander #3 Fine Grinder Collector (4th Floor, B Mill) i) Expander/Extruder/Pre-Gel Dust Collector (4th Floor, B Mill) j) NW Dust Collector (4th Floor, B Mill) k) NC Dust Collector (6th Floor, A Mill) l) NE Dust Collector (6th Floor, A Mill) m) SW Dust Collector (6th Floor, A Mill) n) SC Dust Collector (6th Floor, A Mill) o) SE Dust Collector (6th Floor, A Mill) p) Bulk Loadout Dust Collector (2th Floor, Bulk Loadout) Proposed Penalty: $12,675.00 |

|

Citation 1/Item 5 Violation: 29 CFR 1910.272(n) Description: Size reduction equipment did not have means to remove ferrous material Equipment: a) Roll Stand #1 East/South (2nd Floor mezzanine, B Mill) b) Roll Stand #2 East/South (2nd Floor mezzanine, B Mill) c) Roll Stand #3 East/South (2nd Floor mezzanine, B Mill) d) Roll Stand #4 East/South (2nd Floor mezzanine, B Mill) e) Roll Stand #5 East/South (2nd Floor mezzanine, B Mill) f) Roll Stand #6 East/South (2nd Floor mezzanine, B Mill) g) South Bram Grinder Bauermeister (1st Floor, B Mill) h) Coarse Roller Mill Unit (4th Floor, D Mill) i) Fines Roller Mill Unit (4th Floor, D Mill) Proposed Penalty: $12,675.00 |

Serious Violations (Training & Preventative Maintenance)

Citation 1, items 2 and 4 covered serious violations regarding employee training and preventative maintenance of equipment. OSHA proposes that employees were not trained annually on common ignition sources and housekeeping practices, and that the 1st floor, C mill dryer did not have an effective preventative maintenance program.

|

Citation 1/Item 2 Violation: 29 CFR 1910272(e)(1) Description: Employees not trained annually on: a) Common ignition sources a) Safety practices (Including housekeeping and use of compressed air) Proposed Penalty: $12,675.00 |

|

Citation 1/Item 4 Violation: 29 CFR 1910.272(m)(l)(i) Description: No preventative maintenance program for grain drying equipment Equipment: Expander #5 Fluid Bed Dryer (1st Floor, C Mill) Proposed Penalty: $12,675.00 |

Willful Violations (Equipment)

Citation 2, Items 1 and 14 covered wilful violations regarding grain processing equipment. These included bonding and grounding switch station flex hoses and failure to promptly correct dust collection system deficiencies.

|

Citation 2/Item 1 Violation: OSH ACT of 1970 Section (5)(a)(1) Description: Pneumatic conveying systems not conductive, bonded, and grounded. Equipment: Switch Staton Flex Hoses (5th Floor, A Mill) Protection Methods: NFPA 61, S:8.3.3.2 (system components to be electrically conductive) NFPA 61, S:8.5.2.2 (bonding and grounding as static ignition source control) NFPA 77, S:15.7.2 (pipes and ducts to be metal and grounded) NFPA 77, S:15.8.1 (prohibited use of non-conductive flexible hoses) Proposed Penalty: $126,6749.00 |

|

Citation 1/Item 14 Violation: 29 CFR 1910.272(m)(2) Description: Failure to promptly correct dust collection system deficiencies Equipment: Pack Line Dust Collector Proposed Penalty: $126,749.00 |

Willful Violations (Housekeeping)

Citation 2, Items 4 through 9 covered wilful violations regarding housecleaning. These include a proposed $633,745 penalty for absence of a compliant combustible dust and fugitive dust housekeeping program to reduce dust accumulations, and workplace safety in several areas of the facilities, and $126,749 for the use of compressed air in the vicinity of running machinery.

|

Citation 2/Item 4/5/6/7/8 Violation: 29 CFR 1910.272(j)(l) Description: Absence of compliant fugitive dust housekeeping program Locations: a) 1st Floor, A Mill b) 1st Floor, B Mill c) 4th Floor, B Mill d) 3rd Floor, F Mill e) Pack Area Proposed Penalty: $633,745.00 |

|

Citation 2/Item 9 Violation: 29 CFR 1910.272(j)(3) Description: Compressed air used in presence of running machinery Protection Methods: See NFPA 61 for guidance on use of compressed air Proposed Penalty: $126,749.00 |

Willful Violations (Safety Systems)

Citation 2, Items 3 and 12 covered wilful violations regarding facility safety systems. These include absence of a compliant employee alarm system and absence of regularly scheduled inspection of safety control equipment such as monitors, sensors, alarms, and interlock equipment.

|

Citation 2/Item 3a/b Violation: 29 CFR 1910.272(d) and 29 CFR 1910.38(d) Description: Absence of compliant employee alarm system Proposed Penalty: $126,6749.00 |

|

Citation 1/Item 12 Violation: 29 CFR 1910.272(m)(l)(i) Description: Absence of regularly scheduled inspection of safety control equipment Proposed Penalty: $126,749.00 |

Willful Violations (Personal Protective Equipment)

Citation 2, Item 2 covers wilful violations regarding personal protective equipment (PPE). OSHA proposes that flame-resistant clothing was not provided to protect employees from potential flash fires in the milling, packaging, and bulk load out areas of the facility.

|

Citation 2/Item 2 Violation: 29 CFR 1910.132(a) Description: Failure to provide flame-resistant clothing Protection Methods: See NFPA 2113 for guidance on use of flame-resistant garments Proposed Penalty: $126,749.00 |

Willful Violations (Maintenance)

The last violations, citation 2, items 10, 11, and 13 cover wilful violations regarding equipment maintenance. This includes scheduled inspections and shut-down for combustible dust cleaning of three gap mills, and regular lubrication as outlined in the manufactures’ operations manual.

|

Citation 1/Item 10a/b Violation: 29 CFR 1910.272(m)(l)(i) and 29 CFR 1910.272(m)(l)(ii) Description: Absence of regularly scheduled mechanical equipment inspections Absence of regularly scheduled lubrication of equipment Absence of regularly scheduled shut-down and cleaning Equipment: North Bauermeister GM-120 Gap Mill (1st Floor, B Mill) Proposed Penalty: $126,749.00 |

|

Citation 1/Item 11a/b Violation: 29 CFR 1910.272(m)(l)(i) and 29 CFR 1910.272(m)(l)(ii) Description: Absence of regularly scheduled mechanical equipment inspections Absence of regularly scheduled lubrication of equipment Absence of regularly scheduled shut-down and cleaning Equipment: South Bauermeister GM-120 Gap Mill (1st Floor, B Mill) Proposed Penalty: $126,749.00 |

|

Citation 1/Item 13 Violation: 29 CFR 1910.272(m)(l)(ii) Description: Absence of regularly scheduled lubrication of equipment Absence of regularly scheduled shut-down and cleaning Equipment: Pregel Bauermeister GM-80 Gap Mill (1st Floor, B Mill) Proposed Penalty: $126,749.00 |

Support the Victims

Several fundraising campaigns have been developed to support the victims and community of Cambria, Wisconsin for the Didion Milling Company corn dust explosion incident. Please visit these campaigns and find out how you can support those involved:

- Pray For Cambria: GoFundMe Campaign

- Support the Block Family: GoFundMe Campaign

- Support the Tordoff Family: GoFundMe Campaign

- General donations for the community can be sent by contacting The Old Mill Foundation

Conclusion

The OSHA citations and penalties give insight into the potential factors leading the severity of the Didion Milling corn mill and the corn milling explosion. In addition, the OSHA information provides information on preventing a grain explosion, corn milling, combustible dust hazards, and combustible corn dust, and as a result, to assist with grain dust and grain handling facilities, workplace safety and food safety. Precautions include more emergency response procedures and train employees in dust explosions and hazard recognition. In addition, ethics training and safety audits should be implemented, as Didion operations repeatedly presenting a falsified cleaning log to food safety auditors. Former Didion Milling Company environmental manager Joseph Winch previously pleaded guilty to conspiracy to conceal violations from regulators by falsifying compliance certifications and providing falsified logs to regulators and and was sentenced to federal prison.

A Didon Vice President pleaded guilty and was convicted of obstructing the Occupational Safety and Health Administration’s investigation of the explosion at the corn mill by making false and misleading statements during a sworn deposition. Lastly, a Clean Air Act Violation and fine was imposed, as a Didion personnel making false Clean Air Act compliance certifications, falsify documents relating to dust cleaning practices in the mill, and the operation of air pollution prevention equipment, risking air pollution and safety environmental disasters. As a result, a criminal prosecution was conducted by the US justice department and the Wisconsin attorney general as a result of the explosions. The company agreed to pay a $1 million fine and $10.25 million to the estates of the five workers who were killed. At least five other Didion employees have pleaded guilty to or been convicted of charges including concealing violations, lying to investigators and falsifying cleaning logs, at the corn mill. The convicted people await sentencing before U.S. District Court Judge James D. Peterson for the Western District of Wisconsin on various charges related to company officials false statements, the mill grain dust explosion incident, and the five workers who were killed, and placing others in grave danger from cover ups.

Information on how to file a safety and health complaint about unsafe work conditions can be found at www.osha.gov/workers/file-complaint.

Information on how to report suspected environmental violations and to maintain workplace safety, may be found at echo.epa.gov/report-environmental-violations from the Environmental Protection Agency’s (EPA) Office of Enforcement and Compliance Assurance.