Published August 6, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Safety Industrial Guidelines and Risks of Combustible Liquids

Combustible liquids play a critical role in various industrial processes, from manufacturing and transportation to storage and usage. Despite their utility, these substances pose significant risks, making their safe handling paramount in industrial safety protocols.

What are Combustible Liquids?

Combustible liquids are defined by their ability to ignite and burn when exposed to an ignition source. According to safety standards, a combustible liquid is any liquid with a flash point at or above 100°F (37.8°C) and below 200°F (93.3°C). These liquids are less volatile than flammable liquids but can still pose serious hazards if not properly managed.

Examples of Common Combustible Liquids

- Diesel Fuel: Widely used in transportation and machinery.

- Kerosene: Commonly used for heating and lighting.

- Motor Oil: Essential in automotive and industrial machinery.

- Hydraulic Fluid: Used in hydraulic systems for power transmission.

Classification of Combustible Liquids

Combustible liquids are classified into different classes based on their flash points, which are critical for determining their potential hazards and the necessary safety measures. According to the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA), combustible liquids are primarily categorized into Class II and Class III.

Class II

- Flash Point: At or above 100°F (37.8°C) and below 140°F (60°C).

- Examples: Diesel fuel, kerosene.

Class III

- Class IIIA: Flash Point at or above 140°F (60°C) and below 200°F (93.3°C).

- Examples: Motor oil, hydraulic fluid.

- Class IIClass IIIB: Flash Point at or above 200°F (93.3°C).

- Examples: Certain lubricating oils.

Understanding these classifications is essential for implementing appropriate safety measures in industrial settings. For instance, Class II liquids, being more volatile, require more stringent controls and handling procedures compared to Class III liquids. The classifications guide the selection of storage containers, transportation methods, and emergency response strategies. Moreover, they influence the design of facilities, including ventilation systems, spill containment measures, and fire suppression systems. By adhering to these classifications, industries can better manage the risks associated with combustible liquids, ensuring a safer working environment.

Compliance with classifications and regulatory standards is mandatory for preventing explosions. Regular monitoring plays a key role in ensuring compliance by:

- Regular Reporting: Submitting storage and handling of combustible liquids

- Audits and Inspections: Conducting regular audits to verify compliance with combustible liquids

- Corrective Actions: Implementing corrective measures when combustible liquids are in hazardous states or risks in facilities.

Material Safety Data Sheets for Combustible Liquids

Material Safety Data Sheets (MSDS) play a crucial role in the safe handling of combustible liquids by providing comprehensive information about their properties, hazards, and safety precautions. MSDS sheets include details such as the chemical composition, flash points, boiling points, and vapor pressures of the liquids, as well as health hazards and first aid measures. They also outline safe handling and storage practices, personal protective equipment (PPE) requirements, and emergency procedures. Access to MSDS sheets enables workers and safety professionals to make informed decisions, implement effective safety measures, and respond appropriately to incidents involving combustible liquids.

Physical and Chemical Properties

Understanding the physical and chemical properties of combustible liquids is essential for their safe management. Key properties include:

Flash Point

The minimum temperature at which a liquid produces enough vapor to form an ignitable mixture with air. A lower flash point indicates a higher risk of ignition.

Boiling Point

The temperature at which a liquid turns into vapor. Liquids with lower boiling points can produce more vapors, increasing the risk of ignition.

Vapor Pressure

The pressure exerted by a vapor in equilibrium with its liquid at a given temperature. Higher vapor pressure means more vapors are present, which can lead to increased combustibility.

These properties influence the safe handling and storage requirements, such as the need for temperature control and ventilation.

Combustible Liquids pose Several Health and safety Risks:

Health Hazards

- Inhalation: Vapors can cause respiratory irritation, dizziness, and long-term health issues.

- Skin Contact: Direct contact can lead to irritation, burns, and dermatitis.

- Ingestion: Can cause severe internal damage and poisoning.

Physical Risks

- Fires: Combustible liquids can ignite easily, leading to fires.

- Explosions: Vapors can accumulate in confined spaces and, upon ignition, cause explosions.

Static Electricity, Pressure, and Temperature

Static electricity, pressure, and temperature are critical factors that can significantly impact the safety of handling combustible liquids, potentially leading to explosions. Static electricity can accumulate during the movement or transfer of combustible liquids, such as during pumping or pouring. If this static charge is not properly dissipated, it can create sparks that ignite the vapors of combustible liquids, causing fires or explosions.

Similarly, pressure changes within storage containers or pipelines can lead to leaks or ruptures, releasing vapors that can ignite if exposed to an ignition source. Temperature variations also play a crucial role; elevated temperatures can increase the vapor pressure of combustible liquids, leading to a higher concentration of flammable vapors in the air. This combination of factors underscores the importance of controlling static electricity, maintaining proper pressure levels, and monitoring temperatures to prevent hazardous incidents in environments where combustible liquids are handled.

Safe Handling Practices

Adhering to safe handling practices is crucial to mitigate risks:

Transportation

- Use approved containers and vehicles.

- Ensure proper ventilation to prevent vapor accumulation.

Storage

- Store in designated areas away from ignition sources.

- Use appropriate containers and maintain proper labeling.

Usage

- Follow manufacturer guidelines.

- Implement spill containment measures.

Proper labeling and documentation are essential to ensure everyone is aware of the hazards and safety protocols.

Personal Protective Equipment (PPE)

Using the right PPE is vital when handling combustible liquids:

Recommended PPE

- Gloves: Chemical-resistant gloves to protect against skin contact.

- Goggles: To prevent eye exposure.

- Respirators: For protection against inhaling harmful vapors.

- Protective Clothing: Flame-resistant clothing to reduce fire risk.

Training and Best Practices

- Regular training on PPE usage.

- Routine checks and maintenance of PPE.

Combustible Liquids and Combustible Dust Interactions

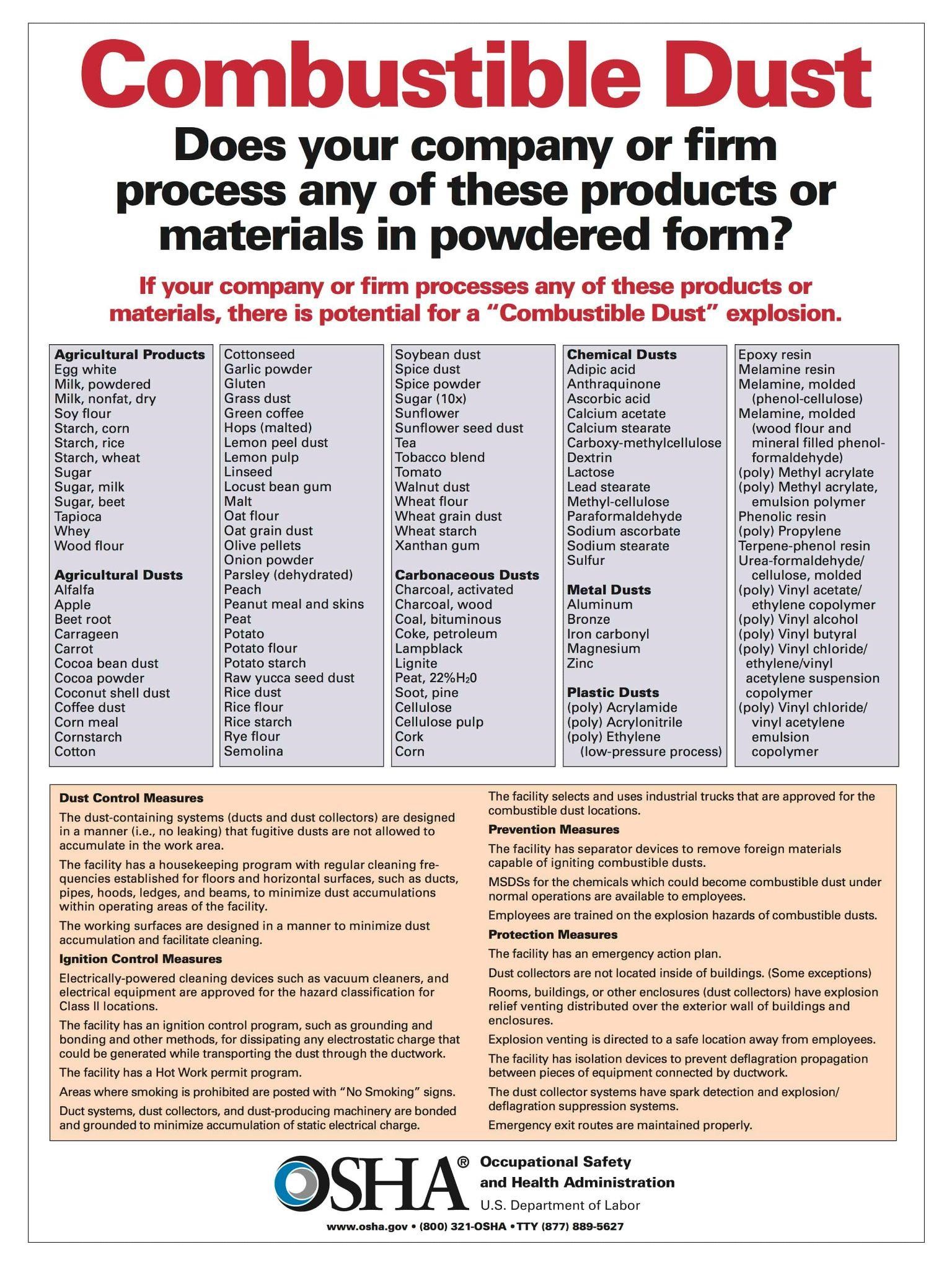

Combustible liquids can exacerbate dust-related hazards. Combustible dust refers to finely divided solid particles that are prone to ignition when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing. The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations.” Dust qualifies as combustible when it possesses specific characteristics that make it prone to ignition and combustion when suspended in the air, as a dust cloud, and as a result create a dust explosion. These key attributes include its particle size, concentration, and chemical composition.

Interaction Mechanisms

- Ignition: Liquid vapors can ignite dust particles, leading to explosions.

- Spread: Combustible liquids can spread fires, increasing the affected area.

Preventive Measures

- Control dust accumulation.

- Implement proper ventilation.

- Use appropriate storage and handling procedures for both liquids and dust.

Engineering Controls and Safety Measures

Engineering controls are essential for facilities handling combustible liquids:

Design Considerations

- Ventilation: Adequate ventilation to disperse vapors and prevent accumulation.

- Spill Containment: Systems to contain and manage spills.

Fire Safety Equipment

- Fire Extinguishers: Suitable for combustible liquid fires.

- Sprinkler Systems: Automated systems to control and extinguish fires.

- Alarm Systems: Early detection and warning systems for fires.

Emergency Response and Fire Fighting Techniques

Proper emergency response and firefighting techniques are crucial:

Procedures

- Spills: Contain and clean up using appropriate absorbents.

- Leaks: Isolate the area and fix the source of the leak.

Firefighting Techniques

- Extinguishing Agents: Use foam, dry chemical, or carbon dioxide extinguishers.

- Approach: Attack from upwind to avoid vapors and flames.

Data-Driven Approaches to Combustible Liquids Management

Data-driven approaches to managing combustible liquids leverage advanced technologies and analytics to enhance safety and efficiency. By collecting and analyzing data from various sources, including sensors, monitoring systems, and historical incident reports, industries can gain valuable insights into the behavior and risks associated with combustible liquids. This data can inform the development of predictive models that identify potential hazards before they become critical issues. For instance, real-time monitoring of storage conditions, such as temperature, pressure, and vapor concentrations, allows for the early detection of anomalies that could lead to fires or explosions. By using data to understand patterns and trends, companies can implement more effective risk mitigation strategies, ensuring the safe handling and storage of combustible liquids.

Control Strategy Adjustments

Adapting control strategies based on data analysis is crucial for maintaining the safety of combustible liquids. Continuous monitoring and data collection enable organizations to make informed adjustments to their safety protocols and response plans. For example, if data indicates an increase in vapor pressure within a storage tank, the system can automatically trigger ventilation adjustments or cooling mechanisms to prevent dangerous vapor buildup. Additionally, data-driven insights can help optimize inventory management, reducing the quantities of combustible liquids stored on-site and thereby minimizing potential hazards. Regularly updating control strategies based on the latest data ensures that safety measures remain effective and responsive to changing conditions, ultimately reducing the risk of incidents involving combustible liquids.

AI and Automation Technologies

The integration of artificial intelligence (AI) and automation technologies significantly enhances the management of combustible liquids. AI-powered systems can analyze vast amounts of data in real-time, providing predictive analytics that help prevent accidents before they occur. For instance, machine learning algorithms can identify patterns in sensor data, predicting equipment failures or hazardous conditions with high accuracy. Automation technologies, such as automated shutdown systems and robotic inspection devices, further improve safety by performing tasks that might be too dangerous for human workers. Automated systems can quickly respond to detected anomalies, such as leaks or temperature spikes, by adjusting operational parameters or initiating emergency protocols. By leveraging AI and automation, industries can achieve a higher level of safety and operational efficiency in the management of combustible liquids, ensuring proactive risk mitigation and swift response to potential hazards.

Conclusion

Understanding and managing the risks associated with combustible liquids is vital for industrial safety. Continuous improvement in safety practices, compliance with regulations, and proper training can significantly reduce the risks and ensure a safer working environment.

Stay informed, regularly review safety protocols, and prioritize the safe handling of combustible liquids in your workplace.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Combustible Liquids and MSDS sheets, with a Podcast. Click on the latest Podcast Link: Adding Combustible Dust Information to Material Safety Data Sheets

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art fire and explosion protection.