Updated September 23, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Key Takeaways:

- Industry Dynamics: The Pulp and Paper industry and Paper Mills operate within a complex framework of processes aimed at transforming raw materials into essential paper products. Each stage, from pulping to finishing, demands meticulous attention to detail to ensure operational efficiency and product quality.

- Hazards of Combustible Dusts: Dust poses a significant threat within the Pulp and Paper industry, primarily stemming from the generation of fine particles during various manufacturing processes. Wood dust, a common byproduct, is particularly concerning due to its inherent combustible nature, potentially leading to combustible dust explosions, fires, and dust explosion hazards, if not managed effectively.

- Specific Concerns: In addition to paper dust and wood dust, the industry grapples with specific concerns related to dust hazards, dust clouds, and dust explosion hazards. Equipment such as grinders, conveyors, and dryers contribute to ignition sources and to the generation and dispersion of fine particles, elevating the risk of ignition. Addressing these concerns requires a comprehensive understanding of the materials, equipment, and processes involved, along with robust safety protocols to mitigate potential risks effectively, which may include performing a dust hazard analysis.

Combustible Dust Hazards, in the Pulp and Paper Industry:

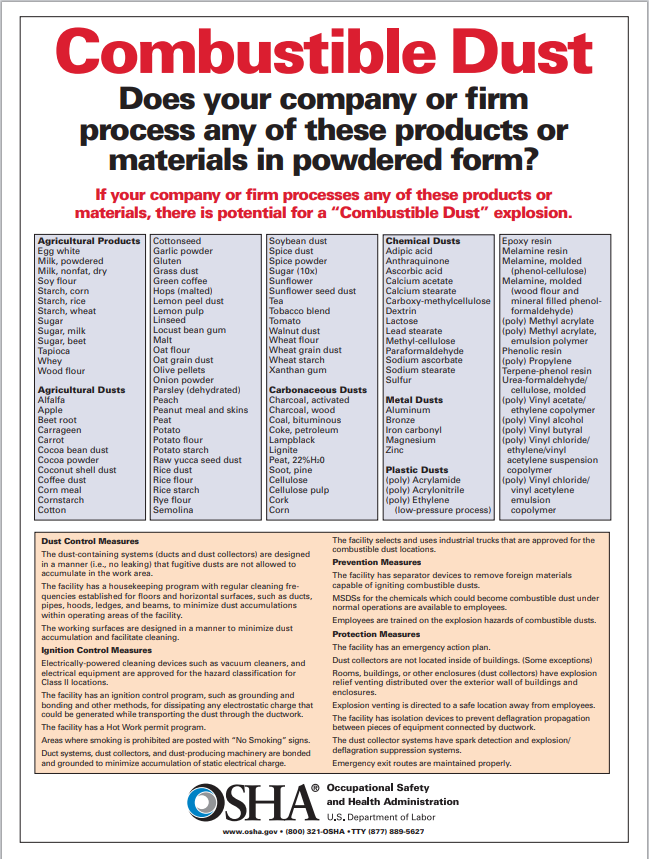

Paper mills play a crucial role in producing a wide range of paper products that are integral to our daily lives. The Occupational Safety and Health Administration, (OSHA), identifies Pulp and Paper as Combustible Dust. Fine particles generated during various stages of paper processing, pulp and paper facilities, and paper machines, such as mixing, cutting, and shredding constitute the primary source of dust in these pulp and paper mills and facilities. From newspapers to packaging materials, this industry contributes significantly to the global market. According to the Environmental Protection Agency, each year U.S. mills produce 9 million tons of pulp and 26 billion books, newspapers, and magazines. The processes involved in paper processing are complex, involving various stages such as pulping, refining, papermaking, and finishing. Each step demands careful attention to detail and adherence to safety protocols to ensure a smooth and efficient production line. In addition, standards such as the National Fire Protection Association, NFPA, recently updated its NFPA 652 combustible dust standard for maintaining clean, safe environments in pulp and paper mills, from dust explosions, for employees, and to protect equipment, which may include performing a dust hazard analysis.

The Pulp and Paper industry faces a significant challenge in managing hazards, and to mitigate dust explosion hazards, and fire hazards which are inherent to several stages of the production process, in pulp and paper mills. One of the primary contributors to these dust explosion hazards is explosive dust, a byproduct generated during the pulping and refining of raw materials. Wood dust possesses combustible properties, and when suspended in the air, it becomes a potential explosion risk with ignition sources from open flames, or hot work surfaces, creating a combustible dust explosion. The finely dispersed particles can accumulate in various areas of the manufacturing facility, creating an environment where the risk of fire, dust clouds, and dust explosion hazards becomes substantial.

Amidst the intricate operations of the Pulp and Paper Industry and Paper Mills, there exists a notable concern related to hazards. Combustible dust refers to fine particles that can ignite when suspended in the air under certain conditions. In the Pulp and Paper industry, these pulp paper dust explosion hazards primarily arise from the materials used, equipment involved, and various industry processes. Dust, a common byproduct in the paper processing industry, possesses combustible properties, making it a potential source of fire and explosion risks. Moreover, the equipment used, such as grinders, conveyors, and dryers, can contribute to the generation of dust. Mitigating combustible dust hazards in the Pulp and Paper industry requires a comprehensive approach that integrates preventive measures and industry best practices, to protect equipment and employees from explosion hazards

Pulp and Paper Industry-Specific Concerns and Root Causes with Combustible Dusts

Within the Pulp and Paper industry, specific concerns regarding hazards revolve around pulp paper critical stages. The pulping phase, where wood is broken down into fibers, can generate fine dust particles that pose a heightened risk. Additionally, the refining process, which involves further treatment of fibers to improve paper quality, demands careful handling to minimize the potential for dust accumulation. Dryers, a crucial component in drying paper sheets, also contribute to the generation of combustible dusts. Addressing these specific concerns requires a comprehensive understanding of the materials, equipment, and processes involved, coupled with robust safety measures to mitigate the risks associated with dust, and to protect employees and to protect equipment, in the Pulp and Paper industry.

Amid the Pulp and Paper industry’s diverse operations, there is a significant concern related to a combustible dust hazard. In this industry, the materials, equipment, and various processes contribute to the generation of dusts, posing potential risks of fire and explosions. Wood dust, a common byproduct in the pulping and refining stages, is inherently combustible, requiring careful handling to prevent the accumulation of dust particles as a combustible dust explosion hazard. The equipment used, including grinders, conveyors, and dryers, adds to the complexity of managing these hazards.

The Pulp and Paper industry and pulp and paper mills must address concerns to mitigate dust explosion hazards. By implementing effective dust control measures, conducting regular risk assessments, and providing adequate training, the industry can minimize the risk of dust explosions, mitigate dust explosion hazards, and protect the well-being of workers and pulp and paper mills. The intricate process equipment involved in these operations increases the risk of friction or mechanical sparks, and hot surfaces, when combined with the dusts suspended in the air, heightens the potential for combustible dust explosions and catastrophic incidents.

Historic Pulp and Paper Industry Related Combustible Dust Explosions

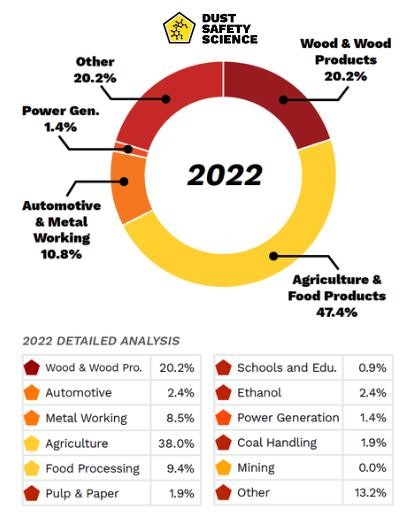

Combustible dust explosions and incidents, continue to occur worldwide and in the Pulp and Paper industry, as presented in this combustible dust research and incident database from Dust Safety Science. In addition, statistics of the most prevalent industries, regarding dust incidents, are also captured in this Annual Incident Report Database, from Dust Safety Science. The Chemical Safety Board (CSB), an independent US government agency, highlights the severity of the issue. Their 2006 report states that wood and paper dust were responsible for 24% of combustible dust explosions in the US over the preceding 25 years. Some of the historic Pulp and Paper dust explosions and incidents include:

- S.D. Warren Paper Mill in Maine in 1987: A significant event occurred at the S.D. Warren Paper Mill in Maine in 1987, where a combustible dust explosion claimed the lives of four workers and injured several others. The explosion, attributed to accumulated paper dust in the mill’s recovery boiler area, prompted widespread scrutiny of safety practices and sparked efforts to enhance dust mitigation measures across paper facilities.

- Atlantic Packaging Products, June 22, 2019: On June 24, 2019, Pulp and Paper Canada reported a three-alarm fire at a paper packaging company in Scarborough, Ontario. Toronto firefighters arrived shortly after 5:06 p.m. on June 22. According to Pulp and Paper Canada, they had to cut through the roof to access the fire and spent about five hours putting it out.

- WestRock (Pulp & Paper) Cardboard Processing Machine, June 12, 2020: An investigation determined that the fire occurred after cardboard dust that had accumulated in the equipment ignited.

The history of dust explosions within the Pulp and paper mills industry serves as a poignant reminder of the persistent dangers inherent in manufacturing processes. By studying these historic pulp and paper mill incidents and implementing proactive measures on pulp paper process equipment, including improved ventilation systems, performing a dust hazard analysis, dust management practices, and employee training programs, the industry can mitigate dust explosion hazards while enhancing workplace safety.

Conclusion

The Pulp and Paper industry and Paper Mills face formidable challenges concerning a combustible dust hazard, requiring proactive measures, which may include performing a dust hazard analysis, to safeguard both personnel and infrastructure from a possible explosion hazard. As highlighted, specific equipment utilized in paper and pulp industries and paper factories, such as grinders and dryers, further exacerbates the risk of dust accumulation, combustible dust clouds, and explosion risk, necessitating continuous monitoring, explosion protection, and mitigation efforts.

Moving forward, the pulp and paper industry and the paper mills industry stakeholders must prioritize comprehensive risk assessments, a process hazard analysis, employee training programs, and the implementation of advanced dust control systems to mitigate the potential for catastrophic incidents. The Pulp and Paper industry can not only enhance operational resilience but also ensure the well-being of workers, protect equipment, and the sustainability of production facilities in the face of flash fire, or an explosive combustible dust hazard.

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible Dust in Waste and EV Factories, visit this podcast episode: Fire Hazards in Waste and Recycling Facilities with Ryan Fogelman

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.