Updated October 9, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Key Takeaways:

- Industry Dynamics: The power generation industry is characterized by diverse energy sources and intricate manufacturing processes aimed at producing electricity to meet global demand. From power plants to renewable energy installations, power generation facilities operate within a dynamic environment shaped by evolving technologies, regulatory frameworks, and market forces.

- Hazards of Combustible Dust: Combustible dust poses significant hazards within the power generation industry, arising from the handling, processing, and combustion of various materials utilized in energy generation processes. Fine dust particles from dust accumulation generated from coal, biomass, and fly ash present inherent risks of combustion and a dust explosion hazard when dispersed in the air under specific conditions.

- Specific Concerns: Several specific concerns regarding combustible hazards arise within the power generation sector, particularly concerning the handling, storage, and processing of materials such as coal, biomass, and fly ash. With coal mines, the pulverization of coal and the combustion of biomass generates fine particulate matter that can accumulate and create dust explosion atmospheres if not properly managed. Additionally, the handling and storage of fly ash present challenges in mitigating dust explosion hazards, necessitating comprehensive dust control measures and preventive actions to minimize the risk of dust-related incidents.

Understanding the Combustible Dust Explosion Hazards, in the Power Generation Industry:

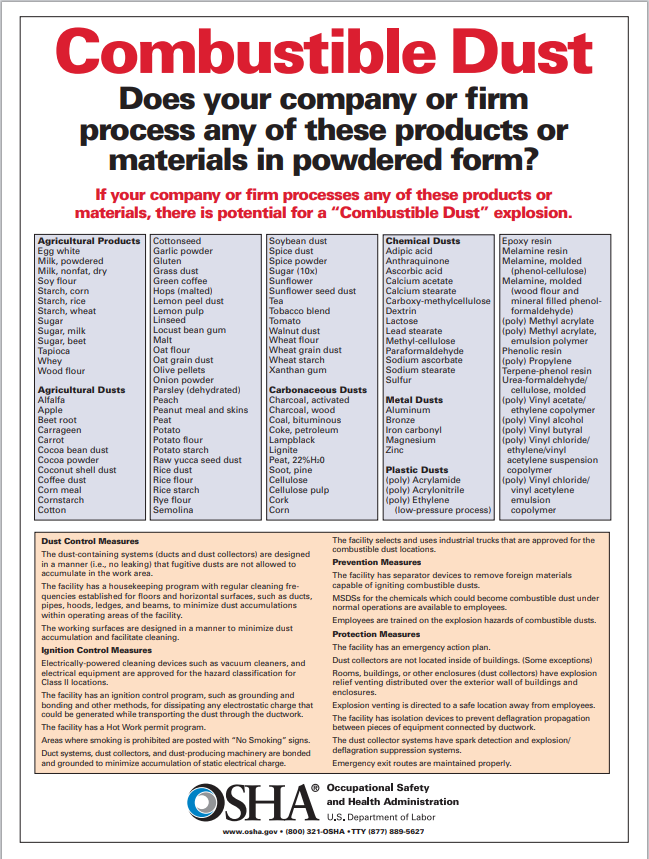

The power generation industry contends with a multitude of materials, equipment, and processes that contribute to the generation of combustible dust. The Occupational Safety and Health Administration, (OSHA), identifies Coal and Biomass as Combustible Dust. Fine dust particulates generated during various stages of coal, biomass, and power generation processing, such as mining, pulverizing, and crushing, constitute the primary source of combustible dust in these facilities. From the pulverized coal used in power plants to the fine particle size generated during biomass combustion, numerous materials pose inherent risks of combustion and explosion when dispersed in the air at certain concentrations. Moreover, the equipment employed in power generation facilities, such as boilers, turbines, and conveyors, often handle materials that can generate dust particulates and a dust cloud through grinding, cutting, or other mechanical actions. These particles, when suspended in the air in specific conditions, with an increased surface area, create an environment ripe for combustion, and a combustible dust explosion, presenting a significant hazard to both personnel and infrastructure within power generation facilities.

In addition to materials and equipment, various industry processes contribute to the proliferation of dust explosion hazards within power generation facilities. For instance, the handling, storage, and transportation of bulk materials like coal, biomass, and fly ash involve activities that can generate and disperse combustible dust particles, and may increase the explosion pressure. Similarly, the combustion processes central to power generation, whether through the combustion of fossil fuels or biomass, produce byproducts that may include fine dust particle size with combustible properties, and create a dust explosion hazard.

Another possible catastrophic event that occurs in coal mines is when a buildup of methane gas, a flammable gas naturally present in coal seams, ignites, causing an initial gas explosion that then disrupts and disperses accumulated and fugitive coal dust, leading to a secondary, more powerful explosion due to the dust cloud igniting in the air, creating increased explosion pressure, and a devastating combined explosion.

Furthermore, maintenance activities such as welding, cutting, and grinding, which are integral to the upkeep of power generation equipment and infrastructure, can generate additional sources dust and form a dust cloud, creating an explosion hazard within facilities. As such, the dynamic interplay of materials, equipment, and process safety inherent to power generation operations underscores the pervasive nature of combustible dust in the industry, necessitating comprehensive risk management approaches to safeguard personnel, assets, and the surrounding environment.

The Power Generation Industry Specific Concerns and Root Causes with Combustible Dust

Within the power generation manufacturing process, the handling and processing of various materials present specific concerns regarding combustible dust. One critical area of focus is the pulverization and handling of coal in a coal-fired plant. Coal, when pulverized into fine dust particles for combustion, increases its surface area, particle size, and susceptibility to ignition when suspended in the air, as dust clouds. Any coal mine, and coal handling facilities, including coal storage silos, conveyors, and milling equipment, are prone to the accumulation of combustible dust, forming dust clouds, necessitating robust housekeeping practices and preventive measures to mitigate the risk of coal dust explosions.

According to Wikipedia, for use in thermal power plants, coal is ground into dust using a device called a powdered coal mill. The resulting product, called powdered coal or pulverized coal, is then generally used in a fossil fuel for electricity generation. Pulverized coal is a significant dust explosion hazard, as large quantities of fine particle size dust are suspended in the air for transfer from the mill to the power plant. Coal dust explosions have previously occurred when the flow drops and flames in the burning chamber pass back along the ductwork delivering fuel. Source: Coal dust

Moreover, the combustion of coal within boilers generates fly ash, a byproduct comprised of fine particulate matter that can exhibit combustible properties. The handling and storage of fly ash present additional challenges in managing combustible dusts within power generation facilities. Fly ash, when agitated or dispersed as a dust cloud, can create explosive atmospheres if allowed to accumulate in a confined space. Therefore, a power plant must implement comprehensive dust control measures, including regular cleaning, ventilation systems, and inerting techniques, to minimize the risk of a coal dust explosion hazard from dust clouds, and safeguard personnel and equipment.

In addition to coal, biomass combustion in renewable energy facilities introduces its own set of concerns regarding dust. Biomass materials, such as wood chips, sawdust, and agricultural residues, contain organic matter that can generate dust when processed or burned. The handling, storage, and combustion of biomass present challenges similar to those associated with coal, necessitating meticulous attention to process safety management practices and the implementation of preventive measures to mitigate the risk of coal dust explosions. By addressing these specific concerns within the power generation manufacturing process, facilities can enhance safety protocols, minimize the likelihood of a dust cloud and coal dust explosion accidents, and uphold operational continuity in the dynamic energy landscape.

According to Alameddin, A. N. and Luzik, S. J., “Coal Dust Explosions in the Cement Industry,” Industrial Dust Explosions, ASTM STP 958, Kenneth L. Cashdollar and Martin Hertzberg, Eds., American Society for Testing and Materials, Philadelphia, 1987, pp. 217-233, The number of coal fired power plants is rapidly increasing because of the high cost and uncertain availability of fuel oil and natural gas.

For many cement producers in the United States, the conversion from chemical manufacturing of fuel oil and natural gas to pulverized coal has been difficult with chemical engineers, and in a few cases, very costly. Most coals used in the firing of kilns have the tendency for spontaneous ignition in accumulated piles. Source: Coal Dust Explosions in the Cement Industry

Historic Power Generation Industry Related Combustible Dust Explosions

Combustible dust incidents, continue to occur worldwide and in the Power Generation industry, as presented in this combustible dust research and incident database from Dust Safety Science. In addition, statistics of the most prevalent industries, and industrial production, regarding combustible dust incidents, are also captured in this Annual Incident Report Database, from Dust Safety Science. Some of the historic Power Generation dust explosions include:

- Angren Thermal Power Plant (January 2021): On January 20, 2021, Xinhuanet reported an explosion at a thermal power plant in Angren, Tashkent Region, Uzbekistan. According to the Uzbek Emergency Situations Ministry, three people were killed and three others injured when a mixture of coal dust and air caused an explosion at around 11:42 a.m. All of the victims were employees carrying out routine maintenance work. There was no damage to the plant’s infrastructure and technological equipment. An investigation into the causes and conditions of the explosion is ongoing.

- GS E&R Energy Company (August 2018): An explosion ripped through a coal-fired power station on Wednesday, leaving one worker dead and four others injured, police said. Police believe that combustible dust could have caused the explosion. Dust, a common source of industrial accidents, easily ignites or even spontaneously combusts when concentrated. Source: Explosion at coal-fired power plant kills 1, injures 4 others

- Didcot Power Station Collapse (2016): According to Wikipedia, the partial collapse of the boiler house at Didcot Power Station in the United Kingdom in 2016 resulted in the deaths of four workers. Additionally, around 50 people were treated for dust inhalation. While the exact cause of the collapse was not conclusively determined, there were reports of a possible explosion due to the presence of combustible dust. This incident underscored the importance of thorough risk assessments and maintenance procedures to prevent catastrophic accidents in power generation facilities. Source: Didcot power stations

- Sago Mine Disaster (2006): Although primarily a coal mining facility, the Sago Mine disaster in West Virginia serves as a pertinent example of the dangers of combustible dust in the coal mine and power generation industry. An explosion in the mine led to the deaths of 12 miners and left one survivor. Investigations revealed that coal dust played a significant role in fueling the explosion. The incident prompted calls for improved safety measures in coal mines and highlighted the importance of controlling combustible dust to prevent catastrophic accidents in coal mining. Source: U.S. Mine Safety and Health Administration (MSHA), Arlington, VA. Sago Mine Report and Sago Mine disaster

Historic power generation industry-related dust explosions serve as reminders of the catastrophic consequences that can result from inadequate dust management practices. Throughout history, numerous incidents have highlighted the inherent risks associated with combustible dusts within power generation facilities, prompting industry-wide scrutiny and the implementation of enhanced safety measures. The power generation industry has witnessed its share of dust explosions, often stemming from the handling and processing of materials such as coal, biomass, and fly ash.

Dust explosions within the power generation industry underscore the imperative of proactive risk management and the implementation of robust dust control measures. By learning from past incidents and prioritizing safety, power generation facilities can mitigate the potential for dust-related accidents and ensure the well-being of workers and surrounding communities. Moving forward, ongoing occupational health training, performing a risk assessment and adherence to best dust hazard analysis practices will be essential in safeguarding against the inherent risks posed by combustible dusts, thereby fostering a safer and more resilient power generation sector, from combustible dust incidents.

Conclusion

The specific concerns surrounding combustible coal dust within the power generation sector underscore the critical importance of implementing comprehensive coal dust control measures and preventive actions. The handling, storage, and processing of materials such as coal, biomass, and fly ash present unique challenges due to the fine particle size of dust generated during coal pulverization and combustion of biomass. These fine dust particles have the potential to accumulate coal dust and form explosive atmospheres, with spontaneous combustion, within power generation facilities if not effectively managed. Moreover, the handling and storage of fly ash further compound the risks, necessitating proactive dust control strategies to minimize the build up of dust and the potential for dust explosions and secondary dust explosions.

The risk of coal dust explosions in the coal, biomass, and power generation industries is a critical safety concern, particularly in coal mines and underground coal mines. The fine coal dust particles that result from mining and handling coal can easily ignite if the concentration of coal dust reaches dangerous levels. In enclosed environments, the conditions are ripe for a catastrophic coal dust explosion, and the increased explosion pressure. The accumulation and coal dust dispersion in underground coal operations significantly increases the risk. To mitigate these risks, industries must implement safety measures like explosion suppression systems and the use of rock dusting techniques, which help dilute the coal dust and prevent the spread of flames during an explosion. Regular monitoring and control of dust concentration are essential to maintain safe working conditions and prevent coal dust explosions.

In addition to explosion suppression, the use of rock dust plays a vital role in managing coal dust explosions. When coal and rock dust are mixed, the rock dust acts as a barrier to flame propagation, helping to control the spread of a propagating coal dust explosion. The introduction of dispersed rock dust reduces the impact of explosions by lowering the concentration of coal dust and decreasing the risk of ignition and heat transfer. Moreover, the maximum explosion pressure that can occur during a coal dust explosion can cause severe structural damage in coal mines. By conducting explosion suppression experiments, engineers can study the explosion characteristics of coal dust under different conditions, identifying the most effective methods to control the pressure rise and prevent widespread devastation in the event of an explosion. Preventing heat transfer and mitigating coal dust explosions are critical in the power generation industry and inside a coal mine.

The interplay of coal dust and gases in coal mine explosions adds another layer of complexity. An initial gas explosion can act as the trigger for a secondary coal dust explosion, with the rapid ignition energy sparking additional explosions throughout underground coal operations. To mitigate this risk, a combination of explosion suppression systems and explosion suppressants is critical. These systems work to contain the explosion by reducing the maximum pressure rise rate and suppressing flames before they can propagate. The importance of rock dusting in these environments cannot be overstated, as it helps manage both coal dust and additional coal dust that could exacerbate an explosion. By integrating these safety practices, industries can significantly reduce the risk of both coal dust explosions and coal mine explosions, ensuring a safer working environment for all involved.

The risk of coal dust explosions in the coal, biomass, and power generation industries is a major concern due to the high combustibility of coal dust particles. When the concentration of coal dust in the air reaches dangerous levels, even a small ignition source can trigger a devastating coal dust explosion. In underground coal mines, where coal dust easily accumulates, this risk is even more pronounced. To mitigate these hazards, safety measures like explosion suppression systems and the use of rock dust are essential. Mixing coal and rock dust helps dilute the flammable coal dust, reducing the chances of flame propagation. The presence of rock dust acts as a protective barrier, lowering the risk of a propagating coal dust explosion. Regular monitoring of coal dust dispersion and keeping the concentration of coal dust below dangerous levels are crucial steps to prevent coal dust explosions in these high-risk environments.

In coal mines, the maximum explosion pressure from a coal dust explosion can cause widespread destruction if not properly controlled. This is why explosion suppression systems are designed to detect the early stages of an explosion and release suppressants to contain the blast before it escalates. Studies of coal mine explosions have demonstrated the importance of controlling coal dust levels, particularly in underground coal mines, where confined spaces amplify the explosion’s force. The implementation of explosion suppression technologies, along with effective rock dusting, significantly reduces the risk of a coal dust explosion. Proper maintenance and regular safety inspections in coal mines ensure that coal dust is kept under control, protecting both workers and equipment from the potentially catastrophic consequences of coal dust explosions.

Addressing these specific coal dust concerns in the power generation industry requires a multifaceted approach that encompasses robust coal dust management protocols, rigorous maintenance practices, and continuous personnel training. By implementing effective coal dust control measures, such as regular cleaning, ventilation systems, and inerting techniques, power generation facilities can mitigate the risk of dust and enhance overall operational safety. Furthermore, proactive preventive actions, including risk assessments, hazard identification, and adherence to regulatory standards from the National Fire Protection Association, are crucial in minimizing the likelihood of dust-related incidents and protecting the well-being of workers and surrounding communities.

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible Coal Dust and Coal Burning, visit this podcast episode: Alternatives to Dust Collection in Coal Burning Applications with Blake Nelson

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.