Updated September 10, 2024 Authored by Dr. Chris Cloney

What Are The Requirements for a Combustible Dust Hazard?

Well this depends on which hazard you are talking about. Handling, manufacturing, or transporting combustible dust can lead to a dust cloud, fires, and a dust explosion, to name a few.

Making things more confusing, these terms are often used interchangeably. Additional concepts such as smouldering fires, deflagration, a primary dust explosion and secondary explosions are also important to understand.

This post gives an overview of the different aspects leading to a hazard and a dust explosion. It explores the triangle, flash-fire square, and explosion pentagon in regards to combustible dust and dust explosions. Other concepts such as smouldering fires, deflagration, and primary dust explosions and secondary explosions are also explored.

Combustible Dust Hazard Requirements

Fire and explosion hazards must be considered in any industries handling, manufacturing, or transporting raw materials, combustible dusts and dust particles. According to the National Fire Protection Association (NFPA) 654 defines combustible dust as “A combustible particulate solid that presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape.” The requirements for different hazards are outlined in the following sections.

Fire Triangle

The triangle is the first set of requirements for a hazard to exist. It states that fuel, oxidant, and an ignition source must be present for a fire to occur.

In the case of combustible dust, the fuel is the powder or finely divided material and the oxidizing agent (oxidant) is oxygen in air for most industrial applications. Lastly, the ignition source can be direct heat, open flames, friction, sparks, static electricity, self-combustion, or any other process that adds energy to the system.

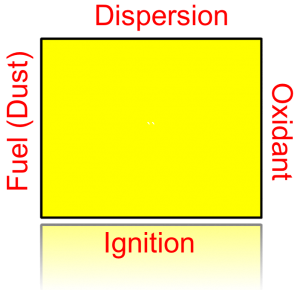

Flash Fire Square

A fire is dangerous on its own as it can destroy property and injure workers. However, the addition of a fourth element, dispersion of the dust, can lead to a fire hazard.

A flash fire is defined by Wikipedia as a “sudden, intense fire caused by ignition of a mixture of air and a disperse flammable substance such as a combustible solid, combustible liquid, or flammable gas”

Flash fires can occur directly by having a fire hazard such as ignition of an open dust cloud or indirectly by dispersing an ongoing dust fire. Both of these hazards have amounted to substantial loss in processing industries and elsewhere. For example, see the Hoeganaes Incident and the New Taipei Water Park Incident for direct fires. Indirect fires injured several last year including workers and first-responders.

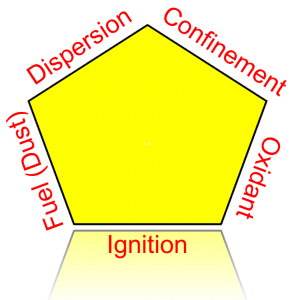

Dust Explosion Pentagon

An explosion can be thought of as a “violent and destructive shattering or blowing apart of something”. In order to have an explosion, there must confinement of the flame propagating in the dust-air mixture.

Confinement is the final element making up the combustible dust explosion pentagon. With confinement of the propagating flame front, pressure will rise which may cause rupture of the enclosure.

It is important to note that complete confinement (e.g., four walls, floor, and a roof, see textbook of Amyotte) is not necessary for combustible dust explosions to reach destructive pressures. Any confinement or confined space, can lead to pressure rise, acceleration of the flame, or pressure piling, which can all increase the explosion violence.

Although the explosion protection approach of venting reduces the amount of confinement, care is needed to size vent panels appropriately to avoid equipment failure.

Other Important Concepts

Several other terms get used frequently to describe an explosion hazard. These are reviewed in the following sections.

Smouldering Fire

But what about smouldering fires? Are they just a dust fire?

As described in a guest post by Dr. Frank Hedlund, a smouldering fire may occur deep inside a pile of dust or powder. A combination of moisture, catalysts, and/or self-heating, can cause smouldering to occur at very low oxidant levels – much lower than possible for a surface fire.

Smouldering fires can be very dangerous as they may burn and catch fire for a substantial period before being detected. Furthermore, they can lead to vessel failure. Again dispersing the smouldering dust can lead to a fire or explosion.

Deflagration vs Detonation

Both deflagration and detonation refer to propagating reaction fronts in solid, liquid, or gaseous mediums. The difference between the two is the speed of front. In a detonation, the front propagates faster than the speed of sound, while in a deflagration the propagation velocity is lower.

Although detonation in dust clouds is physically possible, virtually all industrial hazards involve deflagration. Deflagration is commonly used to describe dust fires and explosions in process safety literature.

Primary vs Secondary Explosion

A primary explosion occurs when the combustible dust cloud is ignited by an ignition source such as heat, sparks, or open flame. This often occurs inside or near running machinery in processing operations with dust present, and a dispersion of dust particles.

Secondary explosions occur when a primary gas or combustible dust explosion disperses accumulated dust and ignites a secondary explosion. These can be particularly devastating as fugitive dust and accumulated dust may be present around the dust collection system equipment, conveyers, or in building rafters. Proper housekeeping at the facility is of fundamental importance on how combustible dust accumulates, to prevent a primary and secondary explosion hazard. A primary dust explosion often leads to a secondary dust explosion.

Summary

In summary, this post reviewed the process of dust hazards including dust particles, particle size, a dust cloud, combustible dust explosions, the triangle, the fire square, the explosion pentagon, smouldering fires, deflagrations, and primary explosions and a secondary dust explosion.

Do you have an example of another hazard from NFPA standards and OSHA standards, not covered in this article? Leave it in the comments below and we will cover it in a future post!