Updated January 24, 2025 Authors: Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Combustible Dust Explosions in Latin America

Dust explosions are a critical safety issue affecting industries worldwide, and Latin America is no exception. These hazardous events, caused by the rapid combustion of fine particulate matter suspended in the air, can lead to catastrophic loss of human lives, economic loss, and environmental damage. As the region continues to grow its industrial sectors, especially in agriculture, mining, and manufacturing, understanding and managing dust explosion risks has never been more urgent.

However, Latin America faces unique challenges in mitigating dust explosion risks due to geographical, industrial, and regulatory factors. By examining the specific causes, risks, and solutions relevant to Latin America, industries and policymakers can better protect workers, assets, and communities.

Addressing this issue requires a comprehensive understanding of the causes, implications, and preventive measures associated with combustible dust. In this article, we delve into the complexities of combustible dust incidents in Latin America, examining their root causes, impact, and strategies for risk mitigation. Combustible dust incidents in Latin America are also covered in What are the Challenges to Combustible Dust Safety in South America?

Understanding Combustible Dust and Combustible Dust Explosions

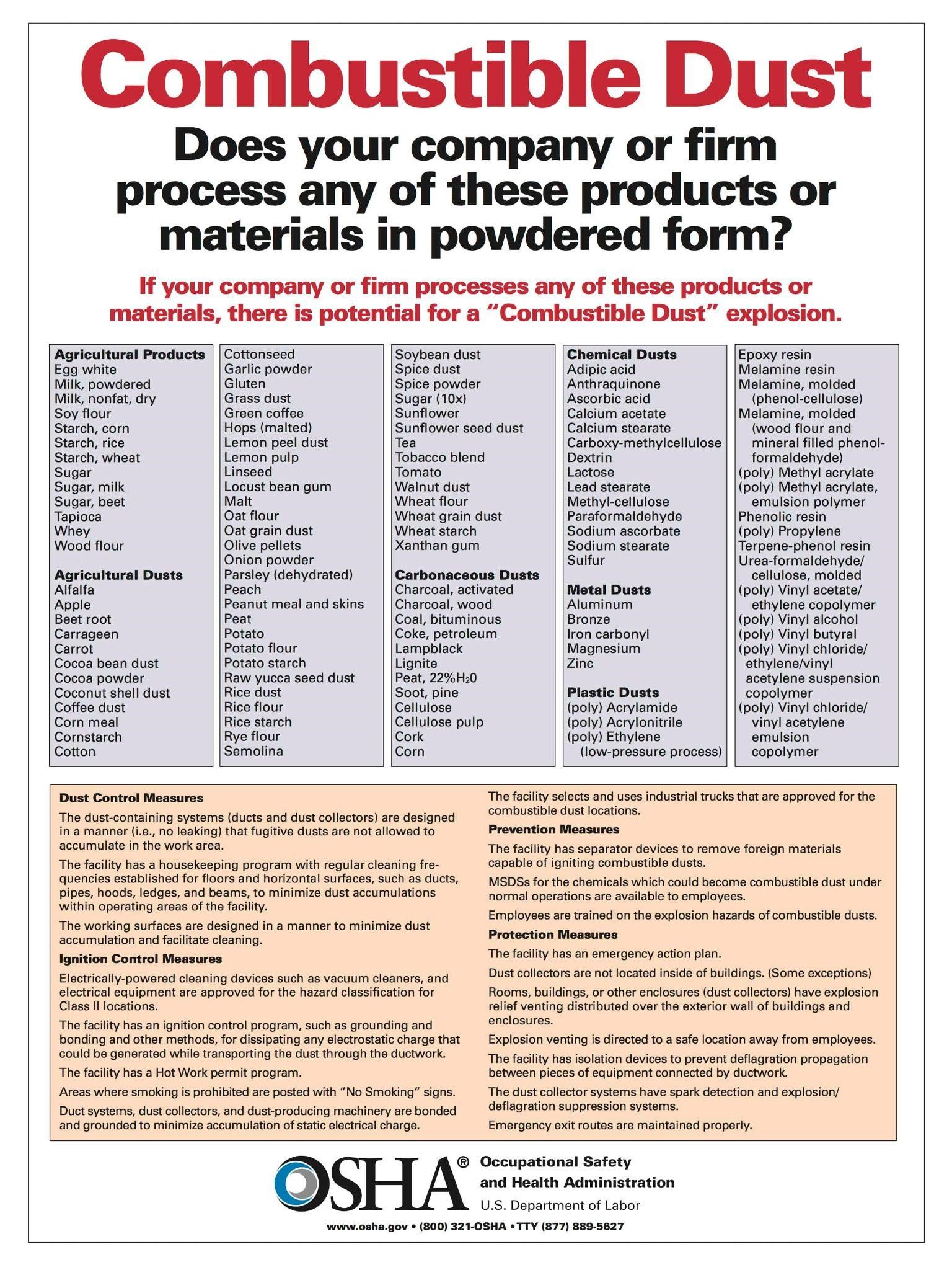

Understanding what combustible dust is and why it poses a significant hazard in industrial settings, is a crucial first step in preventing combustible dust explosions and combustible dust incidents. Combustible dust refers to fine particles or powders that accumulate during various manufacturing, including chemical manufacturing, metal processing, or handling operations. These particles can originate from a wide range of most solid organic materials, and some nonmetallic inorganic materials and solid material including metals, plastics, grains, and chemicals. Materials prone to causing dust explosions include various agricultural products (e.g., grains, flour, sugar), metals (e.g., aluminum, magnesium), coal, wood, chemical dusts, and other organic materials. Industrial environments handling, storage or processing these most solid organic materials are particularly vulnerable to a flash fire and dust explosion hazard.

When dispersed in the air in high concentrations, combustible dust becomes highly explosive with more surface area and an explosion hazard. Even a small spark or heat source can ignite the dust cloud, leading to a rapid combustion reaction known as a deflagration. The force generated by such an event can cause a flash fire and devastating explosions, destroying entire facilities and endangering workers’ lives.

The Science Behind Dust Explosions: The Dust Explosion Pentagon

The Dust Explosion Pentagon expands on the traditional Fire Triangle, comprising five key elements required for a dust explosion:

- Fuel: Combustible dust particles

- Oxidant: Typically oxygen in the air

- Ignition Source: A heat source like a spark, friction, or open flame

- Dispersion: Dust particles must be suspended in the air

- Confinement: An enclosed or semi-enclosed environment where pressure can build up

Removing or controlling any of these elements can significantly reduce the risk of a dust explosion. A fire triangle is the first set of requirements for a hazard to exist. It states that fuel, oxidant, and an ignition source must be present for a fire to occur. In the case of combustible dust, the fuel is the powder or finely divided material and the oxidizing agent (oxidant) is oxygen in air for most industrial applications.

Historical Dust Explosion Prevalence in Latin America

Dust explosions are not limited to any single region or industry, but Latin America has seen notable incidents over recent decades, emphasizing the need for targeted prevention. According to global data, approximately 200–300 dust explosions are reported yearly across various industries. While Latin America lacks comprehensive regional statistics, individual cases highlight the seriousness of this hazard.

Notable Case Studies in Latin America:

- Mexico, 2010: An explosion at a food processing facility in the state of Jalisco, the Jose Cuervo tequila factory, including agave, the key ingredient in tequila, resulted in significant injuries and production losses, bringing to light the need for improved safety standards in food processing.

- Argentina, 2019: An explosion at a grain silo, involving cereal, in Rosario emphasized the risks associated with poor dust management in agriculture.

- One of the most recent and tragic incidents occurred at a feed factory in Jaguapitã, Paraná, where an explosion resulted in the loss of one worker’s life and severe injuries to two others. While the exact cause of the explosion is still under investigation, initial reports suggest that combustible dust may have played a significant role.

- In another recent incident, at least eight people were killed and nearly a dozen were injured after a grain silo explosion in the city of Palotina, Parana State, Brazil, occurred on July 27, 2023. The silo where the explosion occurred stored about 12,000 metric tons of soybeans and 40,000 metric tons of corn.

- A previous combustible dust explosion, Two Workers Injured When Welding Spark Ignites Dust Explosion in Brazil, in November 2022. At the time of the explosion, the two workers were welding on some metal structures. It is believed that a welding machine spark ignited the explosion.

- An additional source of a combustible dust incident in Brazil includes Silo Blast in Southern Brazil Kills at Least Eight, One Missing

Combustible dust incidents, continue to occur worldwide and in many industries, as presented in this combustible dust research and incident database from Dust Safety Science. Over 120 combustible dust incidents have occurred just in the last 5 years, in Brazil.

Root Causes of Combustible Dust Incidents in Latin America

Several factors contribute to the accumulation and ignition of combustible dust in Latin America. Understanding these root causes is crucial for implementing effective preventive measures. Some common factors include:

- Costs: Monica Remonato stated during a Dust Safety Science Podcast that pricing is often an issue when buying dust safety equipment in Latin America. “The taxes are really high. We don’t have a Brazilian industry that can make this spark detector or that fire suppression system. I don’t know why the taxes are so high. So this is the real challenge: the price.” She expressed hope that as awareness increases, some vendors will start manufacturing in Brazil and, hopefully, make their equipment more affordable in that country.

- Awareness and Education: Effective and specifically tailored education and training programs are essential for equipping workers with the knowledge and skills to identify, prevent, and respond to combustible dust hazards. To overcome language barriers, it’s imperative to adopt a multi-pronged approach. This involves translating safety resources, training materials, and signage into local languages and dialects prevalent in industrial regions.

- Inadequate Housekeeping: Failure to properly clean and maintain work areas can lead to the accumulation of combustible dust. Dust buildup on surfaces, equipment, in a confined space, suspended ceilings, and on exterior and interior surface area of an HVAC system increases the risk of ignition.

- Ventilation Maintenance: Inadequate HVAC and dust control systems allow dust particles to remain suspended in the air, creating an environment conducive to explosions. Proper ventilation is essential for controlling dust concentrations and preventing the formation of explosive mixtures.

- Equipment Malfunction: Malfunctioning machinery or equipment can generate sparks or heat, igniting nearby piles of dust. Regular maintenance and equipment inspection are essential for identifying and addressing potential ignition sources.

- Static Electricity: Static electricity can accumulate on surfaces and materials, especially in dry environments. When discharged, static electricity can ignite combustible dust clouds, leading to explosions. Implementing static control measures is critical for mitigating this risk.

- Ignition Sources: External ignition sources, such as open flames, hot surfaces, electrical sparks, and frictional heat, can trigger combustible dust explosions. Identifying and eliminating potential ignition sources is essential for preventing accidents.

Impact of Combustible Dust Incidents in Latin America

The consequences of combustible dust incidents can be severe, affecting human lives and economic stability. Combustible dust explosions often result in injuries and fatalities among workers. The loss of life not only devastates families and communities but also raises concerns about workplace safety and regulatory compliance. Some of the key impacts of combustible dust incidents are:

- Explosions and fires caused by combustible dust can cause extensive damage to industrial facilities, equipment, and infrastructure. The cost of repairs and rebuilding can be substantial, impacting businesses and local economies.

- Combustible dust incidents may release harmful pollutants and toxins into the environment, posing air and water quality risks. Cleanup and remediation efforts are necessary to mitigate environmental damage and protect ecosystems.

- Companies found liable for combustible dust incidents may face legal action, fines, and penalties. Moreover, insurance premiums may increase, and investors may reconsider their support for businesses with a history of safety violations.

Combustible Dust Preventive Measures and Best Practices for Latin America

Mitigating the risks associated with combustible dust requires a multi-faceted approach encompassing engineering controls, administrative measures, and worker training. Conducting a thorough hazard assessment to identify areas prone to dust accumulation and potential ignition sources is the first step in mitigating risks. Some of the preventive measures and best practices include:

- Housekeeping Practices: Implementing regular cleaning schedules and housekeeping procedures helps minimize particulate accumulation in work areas which creates dust, and clean above suspended ceilings, to prevent a primary explosion. Using explosion proof vacuum systems equipped with anti static HEPA filters designed for very small particles and other hazardous cleaning methods can effectively remove dust without dispersing it into the air.

- Ventilation Systems: Installing and maintaining effective ventilation systems is crucial for controlling dust concentrations and preventing the formation of explosive atmospheres. Local exhaust ventilation and dust collection systems should be designed to capture and remove dust at the source.

- Equipment Design and Maintenance: Selecting dust collection system equipment and machinery with built-in safety features, such as spark detection and explosion suppression systems, can help reduce the risk of ignition. Regular inspection, maintenance, and repair of equipment are essential for ensuring their safe operation.

- Static Control Measures: Implementing static control measures, such as grounding and bonding, prevents the accumulation of static electricity on surfaces and materials. Conducting static audits and implementing static dissipative materials can further minimize the risk of electrostatic discharge.

- Ignition Source Control: Eliminating or minimizing potential ignition sources, such as open flames, hot surfaces, and electrical equipment, reduces the likelihood of dust explosions. Implementing hot work permits, using intrinsically safe electrical devices, and enforcing smoking bans are effective strategies for controlling ignition sources.

- Training and Education: Providing comprehensive training and education to workers on the hazards of combustible dust, safe work practices, inspection above suspended ceilings, and emergency response procedures is essential for promoting a culture of safety. Workers should be aware of the risks associated with their tasks and equipped with the knowledge to prevent accidents.

- Emergency Preparedness: Developing and implementing emergency response plans, including evacuation procedures, communication protocols, and firefighting strategies, ensures a timely and effective response to combustible dust incidents. Conducting regular drills and simulations prepares workers for handling emergencies and minimizing their impact.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), for Combustible Dust in Latin America

The integration of advanced technologies, such as Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT), is transforming combustible dust safety practices in Latin America. AI and ML algorithms can analyze vast amounts of data in real-time to predict dust accumulation risks, identify patterns in dust formation, and detect potential ignition sources before dust become hazardous and catch fire. By applying predictive analytics, these technologies enable facilities to implement preventive measures based on risk forecasts, thus minimizing the likelihood of dust explosions. Additionally, AI-driven image recognition can be used to monitor the dispersion of dust particles and trigger alerts if the dust concentration reaches dangerous levels, giving workers and operators critical time to address issues before they escalate, and prevent a flash fire, primary and secondary dust explosions.

The IoT enhances these capabilities by connecting devices and sensors throughout facilities, creating a network that continuously monitors environmental conditions. Sensors placed in key areas, such as silos, manufacturing equipment, and storage rooms, can detect parameters like temperature, humidity, and particulate concentration, preventing any dust to catch fire. When connected to AI-powered analytics, IoT devices can autonomously adjust ventilation systems or activate dust collectors to maintain safe conditions. These innovations are particularly beneficial in Latin America, where industrial sectors like agriculture, mining, and manufacturing face unique challenges in dust management. The combined application of AI, ML, and IoT not only elevates safety standards but also promotes efficiency by reducing unplanned downtime and equipment wear caused by particulate accumulation, allowing industries to operate more sustainably and safely.

Conclusion

Combustible dust explosions pose significant risks across Latin America, especially in sectors where combustible materials are prevalent. Addressing these risks requires a collaborative approach among industry, government, and safety organizations. Implementing advanced dust control measures, investing in employee training, and adopting international standards are all critical steps toward a safer industrial landscape in Latin America.

To combat the risks associated with combustible dust, industry stakeholders, regulatory bodies, and policymakers must collaborate to develop and enforce robust safety standards and regulations. Resources like the International Occupational Hygiene Association of South America provide valuable guidance and best practices for managing combustible dust hazards with organic materials and some nonmetallic inorganic materials. Additionally, research institutions and academic organizations are vital in advancing our understanding of dust explosion dynamics and developing innovative mitigation strategies.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust Incidents in Latin America, with a Podcast. Click on these Podcast Links: Combustible Dust Safety in Brazil and 2020 Conference Review with Monica Remonato and Dust Explosion Prevention and Protection in Brazil with Jay Juvenal

Resources:

Visit: Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Visit: Dust Safety Science’s Training Page

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art fire and explosion protection.