Published June 5, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

A picture of a dust explosion on a conveyor belt, inside a food processing facility

What Causes a Dust Explosion?

Combustible dust refers to fine particles suspended in the air, capable of igniting under certain conditions, leading to fires or dust explosions. When these particles accumulate on surfaces and suspended ceilings and encounter an ignition source, the resulting dust explosion can be devastating. These airborne particles can ignite with a spark or flame, leading to combustion and potentially causing a fire or dust explosion. Other materials and products, such as grain dust, flour, paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are not combustible in larger pieces but can be when pulverized to fine dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials. Various materials can produce combustible dust. Some common combustibility examples include:

- Metals: Aluminum, magnesium, titanium

- Organic materials: Wood, grain, sugar, flour

- Chemicals: Pharmaceuticals, certain plastics, coal

Smoldering Fire and Its Role in Dust Explosions

A smoldering fire can act as a hidden ignition source for dust explosions. Unlike open flames, smoldering fires can persist unnoticed in dust accumulations or equipment. If disturbed, these fires can ignite suspended dust, leading to a devastating dust explosion. Regular inspections and thermal imaging monitoring can help detect and extinguish smoldering fires before they become hazardous.

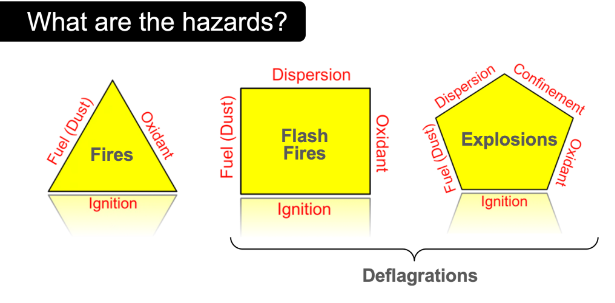

The Dust Explosion Pentagon

To understand how dust explosions occur, it’s helpful to visualize the dust explosion pentagon, which outlines the five essential elements required for a dust explosion:

- Fuel: The combustible dust itself

- Oxygen: Present in the air

- Heat: An ignition source, such as a spark or hot surface

- Dispersion: The dust must be suspended in the air

- Confinement: The dust cloud must be within an enclosed or semi-enclosed space

All five elements must be present for a dust explosion to occur. Removing any one of these elements can prevent an explosion.

What is the Chimney Effect

The chimney effect plays a significant role in the propagation of dust explosions. When a confined space, such as a silo or duct, experiences a dust explosion, the rapid expansion of a dust cloud or gases can create an upward draft, intensifying the fire and spreading it to other areas. This chimney effect process can lead to secondary explosions, making the initial incident even more catastrophic.

Combustible Dust Explosion: Real-World Examples

Numerous incidents highlight the devastating potential of combustible dust explosions. One notable example is the 2008 explosion at the Imperial Sugar refinery in Georgia, USA. The dust explosion resulted from sugar dust accumulation, leading to 14 deaths and numerous injuries. This tragedy underscores the importance of stringent dust monitoring and hazard analysis.

Combustible Dust Examples in Industry

Different industries face varying levels of risk from combustible dust. Here are some combustible dust examples from various sectors:

In agriculture, grain dust from crops like wheat, corn, and soybeans can create explosive atmospheres in silos and storage facilities. The handling and processing of these materials must be managed carefully to prevent dust accumulation.

Woodworking operations, including sawmills and furniture manufacturing, generate large amounts of wood dust. Proper dust collection systems and regular cleaning are crucial to minimize risks.

Chemical manufacturing plants often deal with powders and granules that can produce combustible dust. Ensuring proper handling and storage, along with effective dust control measures, is essential for safety.

Food processing facilities, processing ingredients like sugar, flour, and spices must be vigilant about dust control. Even small quantities of dust can create dangerous conditions if allowed to accumulate.

Metalworking processes, such as grinding and cutting, can generate fine metal dust that poses a significant explosion risk. Proper ventilation and dust collection systems are vital in these environments.

Understanding Relevant Standards and Regulations, Regarding Dust Explosion Compliance

The Occupational Safety and Health Administration, OSHA, sets forth regulations related to grain handling facilities in the United States. These regulations, outlined in OSHA’s Grain Handling Facilities Standard (29 CFR 1910.272), cover requirements for:

- Housekeeping: Mandating regular cleaning to control dust accumulation.

- Grain Dryer Safety: Establishing guidelines for the safe operation of grain dryers.

- Preventative Maintenance: Requiring regular inspection and maintenance of equipment.

- Emergency Planning: Ensuring facilities have emergency action plans in place.

The National Fire Protection Association, NFPA, provides guidelines for the prevention of dust explosions in agricultural and industrial settings. NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities, includes recommendations for:

- Dust Control: Implementing measures to minimize dust generation and accumulation.

- Ignition Source Control: Identifying and mitigating potential ignition sources.

- Explosion Protection: Installing explosion protection systems to mitigate the impact of explosions.

Attrition Combustible Dust: A Hidden Danger

Attrition refers to the process of materials breaking down into finer particles due to friction or wear. This process can produce attrition combustible dust, which may not be initially obvious but can pose significant risks. For instance, mechanical processes like grinding, cutting, or conveying can generate fine dust particles that accumulate over time, creating a hazardous environment.

Preventing Combustible Dust Explosions

Preventing combustible dust explosions requires a multi-faceted approach. Here are some key strategies:

- Housekeeping: Regular cleaning and removal of dust accumulations are essential to prevent dust buildup. This includes cleaning hard-to-reach areas where dust might settle.

- Equipment Maintenance: Proper maintenance of equipment to prevent overheating and sparks is crucial. Regular inspections can help identify potential ignition sources.

- Ventilation: Adequate ventilation helps disperse dust particles, reducing the likelihood of suspension in the air. Ventilation systems should be designed to handle the specific dust types present in the facility.

- Explosion Protection Systems: Installing explosion protection systems, such as explosion vents, suppression systems, and isolation devices, can help mitigate the impact of an explosion.

- Training and Awareness: Educating employees about the risks of combustible dust and training them in proper safety procedures is vital. Workers should know how to handle materials safely and respond in the event of an incident.

Dust Monitoring and Dust Hazard Analysis

Effective dust monitoring and dust hazard analysis are critical for preventing combustible dust explosions. Monitoring involves regular inspection and measurement of dust levels in the workplace to ensure they remain within safe limits. Tools like dust sensors and explosion venting systems can help detect and mitigate potential hazards.

A comprehensive dust hazard analysis (DHA) involves evaluating the workplace to identify areas where combustible dust could accumulate and pose a risk. A dust hazard analysis should consider factors like dust particle size, potential ignition sources, and the likelihood of dust dispersion and confinement. Based on the findings, appropriate safety measures and controls can be implemented.

Conclusion

Combustible dust explosions are a serious threat that requires diligent attention and proactive measures. By understanding the properties of combustible dust, the dynamics of the dust explosion pentagon, and the importance of effective dust monitoring and dust hazard analysis, industries can significantly reduce the risk of such dust explosion incidents. Implementing dust explosion safety practices, maintaining equipment, and fostering a culture of awareness and training are critical steps toward ensuring a safe working environment, with dust explosion compliance.

About Dust Safety Science

For more from Dr. Chris Cloney on Dust Collector Systems, visit this Podcast: Avoiding the Chimney Effect when Fighting Grain Dryer Fires

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.