Published December 30, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Prevent Dust Explosions in Argentina with Expert Training: Protect Lives and Reduce Risks

Dust explosions pose a critical safety risk in various industries worldwide, including Argentina. Industries such as agriculture, food processing, mining, and manufacturing are particularly vulnerable to these hazards due to the abundance of combustible materials and the lack of stringent safety measures. Past and present dust explosions in Latin America highlight the pressing need for comprehensive safety protocols and combustible dust training to mitigate risks effectively. Some of the countries in Latin America affected by combustible dust explosions include: Argentina, Mexico, Brazil, Peru, Colombia, Bolivia, Venezuela, Costa Rica, Panama, Puerto Rico, Chile, Paraguay, Ecuador, Guyana, Uruguay, Suriname, French Guiana, the Falkland Islands (UK), Belize, El Salvador, Guatemala, Honduras, Nicaragua, Cuba, Dominican Republic, Haiti, Guadeloupe, Martinique, Saint-Barthélemy, and Saint-Martin.

One of the most effective methods for addressing combustible dust hazards is Dust Hazard Analysis, (DHA). A DHA is a proactive measure to identify potential risks and implement controls to prevent dust explosions. This article explores the importance of dust explosion safety in Argentina, provides an overview of DHA, and emphasizes the need for targeted training programs to enhance industrial safety. Beyond the tragic loss of life, dust explosions can cause extensive property damage, production downtime, and financial setbacks. Combustible dust, produced in manufacturing operations, can ignite under the right conditions, leading to explosions with catastrophic consequences.

Every year, combustible dust explosions and incidents happen across all manufacturing industries, causing widespread destruction, injuries, and even loss of life. The financial toll is staggering, with billions in property damage and legal costs. Despite the risks, many industrial facilities and manufacturing plants must tackle the challenges of combustible dust.

The question is: Are you doing enough to protect your business and employees from dust explosions? To create a safer workplace, visit Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training.

The Devastating Consequences of Dust Explosions

Combustible dust incidents don’t just cause physical damage, they devastate lives. Workers face injuries or fatalities, businesses lose productivity, and the aftermath often leads to reputational damage and regulatory fines. To address this hidden threat, proactive safety measures are essential. Enter Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training a game changer in industrial safety.

Combustible Dust Safety Training: A Necessary Defense

Safety training empowers businesses to identify, control, and mitigate combustible dust hazards. A well-structured training program ensures compliance with standards, enhances workplace safety, and promotes operational efficiency.

To take the first step toward creating a safer workplace, visit Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training. The training solutions equip organizations to handle combustible dust risks effectively.

Understanding Combustible Dust Explosions

What is Combustible Dust?

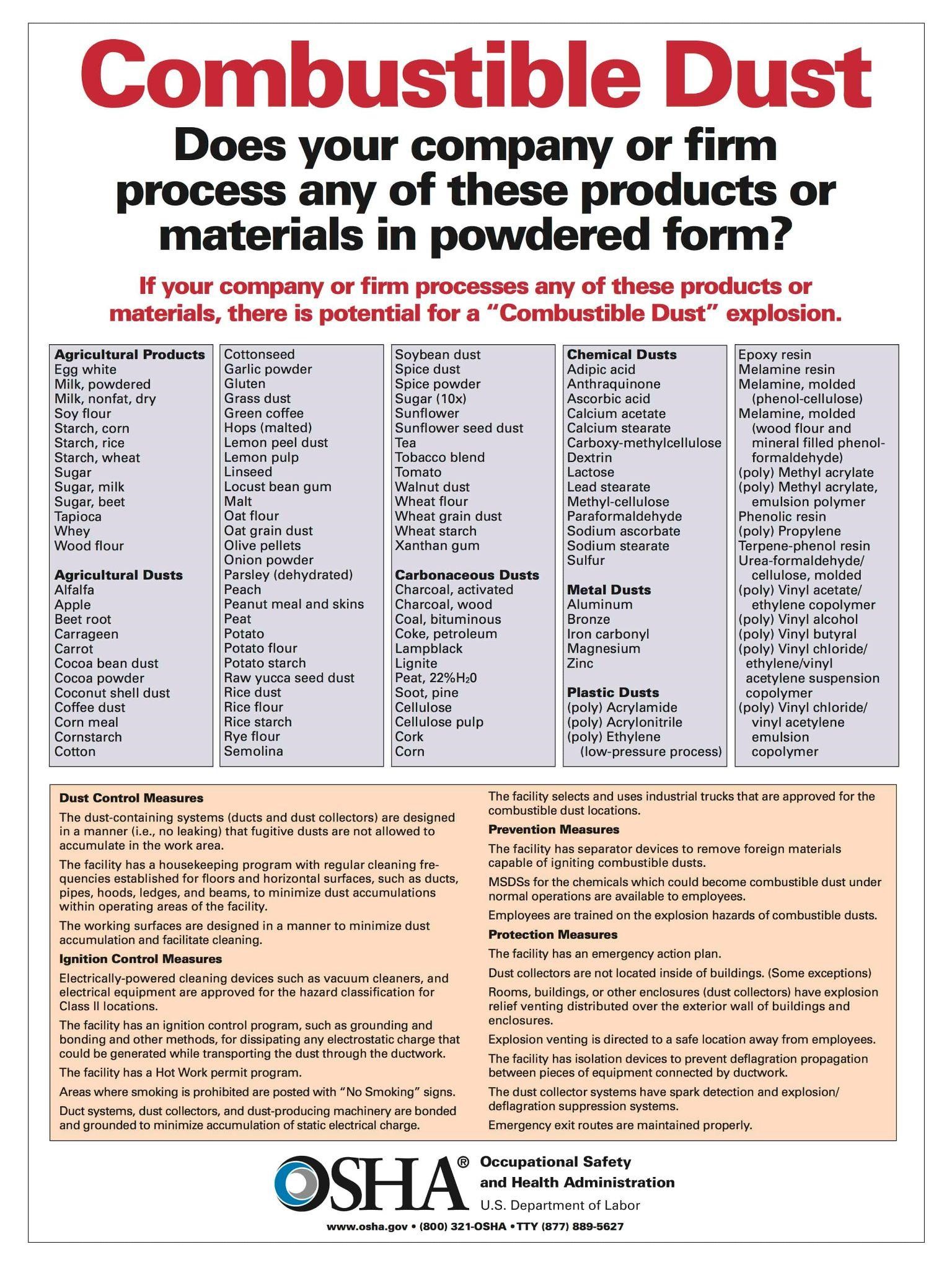

Combustible dust is made of fine particulate solids that can ignite and explode when dispersed in the air. These particles, ranging from flour, and wood to powdered metals, form an explosive mix when conditions are optimum.

The Dust Explosion Pentagon identifies five critical elements required for a dust explosion:

-

Fuel: Combustible dust.

-

Oxygen: Present in the air.

-

Ignition Source: Heat, sparks, or flames.

-

Dispersion: Particles suspended in air.

-

Confinement: Enclosed spaces that amplify explosive force.

When all five elements converge, the results can be catastrophic.

Common Causes of Dust Explosions in Argentina

-

Overheated Bearings: Inadequately maintained equipment is a frequent ignition source.

-

Electrical Failures: Faulty wiring, static electricity, or faulty equipment can lead to sparks.

-

Dust Accumulation: Poor housekeeping allows dust to collect and become a serious hazard.

-

Mechanical Malfunctions: Equipment failures can generate heat and friction, igniting dust clouds.

Industries at Risk of Combustible Dust Explosions

While combustible dust hazards exist in many industries, some industries are more prone to combustible dust explosions than others:

-

Food Processing: Soybean, flour, coffee, rice, cotton, beans, cacao, wheat, cocoa, sugar, corn, maize, nuts, and grain dust.

-

Woodworking: Sawdust and fine wood particles

-

Pharmaceuticals: Fine powders, plastics, and chemicals.

-

Biomass: Wood, wood residues, tobacco, energy crops, agricultural residues including straw, peat, and organic waste from industry and households.

- Coal: Coal Mines, coal dust, and Coking coal dust

- Metalworking: Aluminum, magnesium, zirconium, and other metallic dust.

Each industry requires customized training to manage unique risks. Learn how tailored training can address these challenges by visiting Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training Dust Safety Science’s Training Page.

Historical Dust Explosion Prevalence in Argentina

Dust explosions are not limited to any single region or industry, but Latin America and Argentina have seen notable incidents over recent decades, emphasizing the need for targeted prevention. According to global data, approximately 200–300 dust explosions are reported yearly across various industries. While Latin America lacks comprehensive regional statistics, individual cases highlight the seriousness of this hazard.

Notable Case Studies in Argentina:

-

Argentina, 1985: According to UPI Archives, two explosions occurred at a grain elevator, at Grain Elevator Number Five at the port of Ingeniero White, which services the Atlantic Coast city of Bahia Blanca.

-

Per research from Roberto D. Hajnal, and published on OpenAgrar, several Grain terminal and grain storage explosions have occurred in Argentina over the past decades.

-

In July 2019, Four Men were Injured in Dust Explosions at the Buenos Aires Cereal Plant.

-

In November 2021, a Fire Appeared in a Dust Collector Sleeve at a Soybean Crushing Plant in San Lorenzo, Santa Fe, Argentina.

-

In March 2021, Firefighters Put Out a Grain Dryer Fire at the Argentinian Farmers’ Cooperative, in Aldao, Santa Fe, Argentina.

-

In October 2022, Two Workers were Injured in a Dust Explosion at an Argentina Agribusiness.

Combustible dust incidents, continue to occur in Argentina and in many industries, as presented in this combustible dust research and incident database from Dust Safety Science.

Why Combustible Dust Safety Training is Crucial in Argentina

Regulatory Compliance

Globally Harmonized System (GHS): Argentina has engaged in the classification and labeling of dust explosion hazards under the GHS framework. Per OSHA, in 2003, the United Nations (UN) adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

The GHS includes criteria for the classification of health, physical, and environmental hazards, as well as specifying what information should be included on labels of hazardous chemicals as well as safety data sheets. The United States was an active participant in the development of the GHS, and is a member of the UN bodies established to maintain and coordinate implementation of the system. The official text of the GHS can be found on the UN web page.

Safety Data Sheets (SDS): Per the Hazard Communication Standard: Safety Data Sheets – Occupational Safety and Health Administration, OSHA, Safety Data Sheets include information such as the properties of each chemical; the physical, health, and environmental health hazards; protective measures; and safety precautions for handling, storing, and transporting the chemical.

Sections 1 through 8 contain general information about the chemical, identification, hazards, composition, safe handling practices, and emergency control measures (e.g., fire fighting). This information should be helpful to those who need to get the information quickly. Examples of the information labeled on the SDS sheet are:

Engineering Measures:

-

Ensure adequate ventilation, especially in confined areas.

-

Minimize workplace exposure concentrations.

-

Apply measures to prevent dust explosions.

-

Ensure that dust-handling systems (such as exhaust ducts, dust collectors, vessels, and processing equipment) are designed in a manner to prevent the escape of dust into the work area (i.e., there is no leakage from the equipment).

Handling and Storage:

- Static electricity may accumulate and ignite suspended dust causing an explosion. Provide adequate precautions, such as electrical grounding and bonding, or inert atmospheres.

Sections 9 through 11 and 16 contain other technical and scientific information, such as physical and chemical properties, stability and reactivity information, toxicological information, exposure control information, and other information including the date of preparation or last revision. The SDS must also state that no applicable information was found when the preparer did not find relevant information for any required element.

The SDS must also contain Sections 12 through 15, to be consistent with the UN Globally Harmonized System of Classification and Labeling of Chemicals (GHS), but OSHA will not enforce the content of these sections because they concern matters handled by other agencies.

Regulatory Agencies and Standards

Regulatory agencies like OSHA and standards like NFPA 652 mandate measures to control combustible dust risks. Failure to comply not only endangers lives but also leads to penalties. Training helps organizations stay compliant and avoid legal consequences.

In addition, NFPA 61, Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities, protects lives and property from fires and explosions in wheat facilities handling, processing, or storing bulk agricultural materials, their by-products, or other agricultural-related dust and materials.

Risk Mitigation

Identifying and mitigating dust hazards is central to a safe work environment. Training programs, such as those offered by Dust Safety Science, provide actionable insights to reduce risks through Dust Hazard Analyses (DHA) and preventive strategies.

Employee Safety

Education is key to empowering workers. Through training, employees learn to:

-

Recognize Combustible Dust Hazards.

-

Use properly rated, Combustible Dust Control Equipment, such as Dust Collectors, Dust Control Fans, and Combustible Dust rated Vacuums.

-

Use personal protective equipment (PPE) effectively.

-

Follow emergency procedures during incidents.

Operational Efficiency

Preventing explosions reduces downtime, maintains productivity, and saves costs associated with accidents. Proper training ensures smoother operations and a safer workplace.

Core Elements of Combustible Dust Safety Training

Dust Hazard Analysis (DHA)

A Dust Hazard Analysis, DHA, is the cornerstone of dust safety. A Dust Hazard Analysis involves identifying hazardous zones, evaluating risk severity, and implementing control measures. Training ensures participants can conduct effective DHAs for their facilities.

Housekeeping and Maintenance

Dust accumulation poses a significant risk. Training covers:

-

Effective cleaning techniques to minimize airborne dust.

-

Preventive maintenance schedules for equipment.

-

Targeting hard-to-clean areas where dust tends to settle.

Ventilation and Dust Collection

Proper ventilation and dust collection are critical to control dust at its source. Training addresses:

-

Designing effective dust collection systems.

-

Ensuring ongoing system inspections and maintenance.

-

Educating staff on the proper use of dust collection equipment.

Ignition Source Control

Ignition sources are often preventable. Training programs focus on:

-

Identifying ignition risks, such as open flames, hot surfaces, and electrical faults.

-

Implementing spark detection and suppression systems.

-

Using explosion-proof equipment in high-risk areas.

Emergency Response Planning

When an incident occurs, preparedness can save lives. Training equips workers with:

-

Evacuation procedures and drills.

-

Fire suppression strategies.

-

First aid skills to handle injuries effectively.

Invest in these essential safety components by enrolling in Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Why Choose Dust Safety Science for Dust Explosion Training in Argentina?

Comprehensive Curriculum

The Latin America Dust Explosion training program delves deep into every aspect of combustible dust safety, from understanding explosion mechanics to fundamentals of dust fire and explosion safety and dust hazard analysis. Learn more at Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Expert Instructors

With a team of seasoned professionals, Dust Safety Science brings unparalleled expertise. Their instructors ensure participants receive actionable, industry-specific guidance.

Flexible Training Options

Choose a format that fits your needs:

-

Online Courses: Flexible and accessible.

-

In-Person Training: Hands-on experience for practical learning.

-

Hybrid Options: A blend of convenience and interactivity.

Customized Training Solutions

Every industry faces unique challenges. Dust Safety Science offers tailored training solutions, that address specific risks and compliance needs. Start customizing your training today by visiting Dust Safety Science’s Training Page.

Take Action: Ensure Your Facility’s Safety Today

Combustible dust is an invisible threat with potentially devastating consequences. Comprehensive safety training is not optional—it’s a necessity. Protect your workforce, reduce risks, and ensure regulatory compliance by investing in professional training.

Start your journey toward a safer workplace today by enrolling in Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training. Learn more about their programs and how they can benefit your organization.

Don’t wait until it’s too late. Visit Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training now to secure your facility’s future.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Combustible Dust Incidents in Latin America, with a Podcast. Click on these Podcast Links: Combustible Dust Safety in Brazil and 2020 Conference Review with Monica Remonato and Dust Explosion Prevention and Protection in Brazil with Jay Juvenal

Resources:

Visit: Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Visit: Dust Safety Science’s Training Page

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.