Guest Author: Jeff Nichols

How to keep from blowing up and burning down your wood pelleting operation.

“You know you are making fuel, right?”

This is a question I often found myself asking as new wood pellet and biomass plants started sprouting up all over the Midwest, Northeastern States, and Canada, but especially here in the Southeast United States. And I didn’t say this to be rude, but to point out potential combustible fugitive dust, dust control, and ignition issues, with fine biomass dust.

We have been making wood flour in North America for decades in the forest products, wood products, secondary wood products, and especially in the MDF Medium Density Fiberboard and other biomass dust related industries. Yet there seemed to be little technology transfer. Especially in fire and explosion prevention and protection, and biomass dust control, from fine biomass dust.

Every engineering firm and large equipment manufacturer seemed to think they could build a wood pellet plant better than the last. So, naturally many of the designs are different. Some are efficient, some not so much. Some are built with the proper engineering controls designed in, for others fire and explosion protection seemed to be an afterthought. My job is to help you with dust control, and prevent these fires and explosions. This is what keeps me up at night.

The Problem

In my job, I get the opportunity and privilege of making site visits to many of these pellet operations, as well as many other various types of combustible fugitive dust in biomass plants, the biomass industry, and processes. Often, there is a disconnect from safety theory to actual practice. I go through many variations of safety orientation at these plants, and then will often be walking through a plant and see posters that say “safety first”, all the while walking around on layers of combustible fugitive dust!

What if I told you fugitive dust could be just as flammable or explosive as gasoline? Or, if I told you wood dust bin explosions are just as powerful as grain elevator explosions? Would that change how you view combustible wood or biomass dust? Examples of biomass dust include wood and wood chips, pruning waste, waste from the food industry, animal manure or oil from seeds.

There are established and reputable conveyor companies who dismiss the idea of building a conveyor that is dust tight. However, if a plant had a combustible gas leak they would not continue to operate. Instead, they would shut down and fix the leak prior to starting back up. Or if they had a fuel, gasoline or other flammable liquids spill, they understand that their first responsibility would be to evacuate the area, fix the problem and clean up the mess.

Yet, when it comes to combustible fugitive dust, and biomass dust we seem to be blind to the potential hazard. Because we work around it every day there tends to develop over time a level of complacency. Prolonged or repeated exposure to fine dust, is problematic. So, training and housekeeping become critical to dust control solutions, preventing fires, explosions and catastrophic secondary explosions.

Complacency kills

Another thing that makes me cringe is hearing someone say, “that’s the way we have always done it”, or “we have been running this way for years”, or “fires are just part of the process”. This is complacency, lack of education to the hazard, and really a lack of respect for the danger of combustible fugitive dust and dust control. Plants change. Machinery wears over time, products change, specifications change. Change management is critical to stay on top of safety. So is constant improvement and training.

Combustible fugitive dust and biomass dust layers on dust collection equipment and machinery, walls, floors, on the rafters, cable trays, conduit, and piping are an indication of this disconnect, complacency, and of a potential combustible fugitive dust incident and dust control. Many times after touring biomass plants with layers of combustible fugitive dust around the plant I find they have indeed had previous fires or explosions. Understand, if you are having fires and explosions, no matter how minor, they are potential precursors to a bigger event. You may be witnessing leading indicators of future problems with fine biomass dust control.

A deflagration is simply a fast moving fire. And a combustible fugitive dust fire is simply a failed explosion – you just haven’t gotten the recipe right, yet!

Any time you move or manipulate a combustible product you are creating friction and heat as well as combustible fugitive dust, and therefore have a potential for fires and explosions.

Fire Triangle and Explosion Pentagon in the Biomass Process

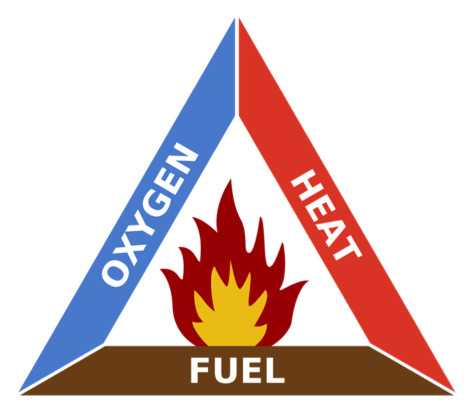

There are three main areas of concern for creating fires in the biomass process – dryers, hammer mills, and pelletizers. Conveyors and other moving machinery such as dust collectors, are also a secondary concern for creating dust emissions with biomass dust, fires, and possible dust explosions. These processes create friction and heat, which is one leg of the Fire Triangle, along with oxygen and fuel. So, you inherently have all the ingredients for a fire in your biomass industry and biomass process.

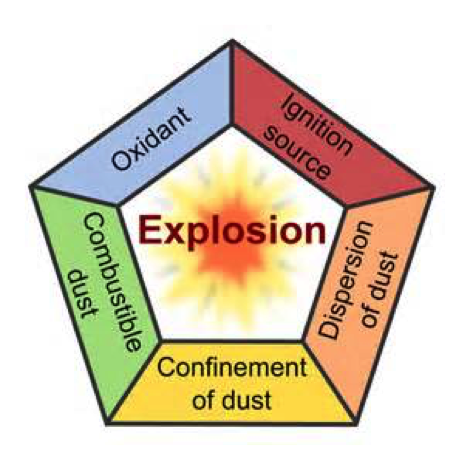

If your biomass dust is in an enclosure that contains dust emissions such as a bin, a dust collector, or dust collection system, you not only have all the ingredients for a dust cloud and fire but have all of the requirements for an explosion.

Having combustible fugitive dust in suspension in a confined area or vessel are the last sides of the dust explosion pentagon. If you are storing wood dust or pellets in enclosures, and/or you have dust collectors, you have all the ingredients necessary for an explosion.

Ignition and Prevention

We see heat, friction, and mechanical sparks as the cause of many of these fires and explosions. According to the 2016 NFPA report “Fires in Industrial or Manufacturing Properties”:

- U.S. fire departments responded to an estimated average of 37,000 fires at industrial or manufacturing properties each year, with annual losses from these fires estimated at 18 civilian deaths, 279 civilian injuries, and $1 billion in direct property damage.

- Structure fires accounted for 20% of the fires, but 47% of civilian deaths, 82% of civilian injuries, and 69% of direct property damage.

- Heating equipment (14% of total) and shop tools and industrial equipment (also 14% of total) were the leading causes of structure fires in industrial or manufacturing facilities.

- A mechanical failure or malfunction was a factor contributing to the ignition of one in four structure fires (24%) in industrial or manufacturing properties, accounting for 23% of civilian injuries and 21% of direct property damage.

The controlling document for protecting wood biomass and wood pellet plants and processes from wood dust, is the NFPA 664 Standard for the Prevention of Fires and Explosions in Wood Processing and Wood Working Facilities.

For agricultural based biomass, see NFPA 61 Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities. NFPA 664 requires a Dust Hazard Analysis (DHA), to identify and mitigate all potential dust collection and ignition hazards, and dust control.

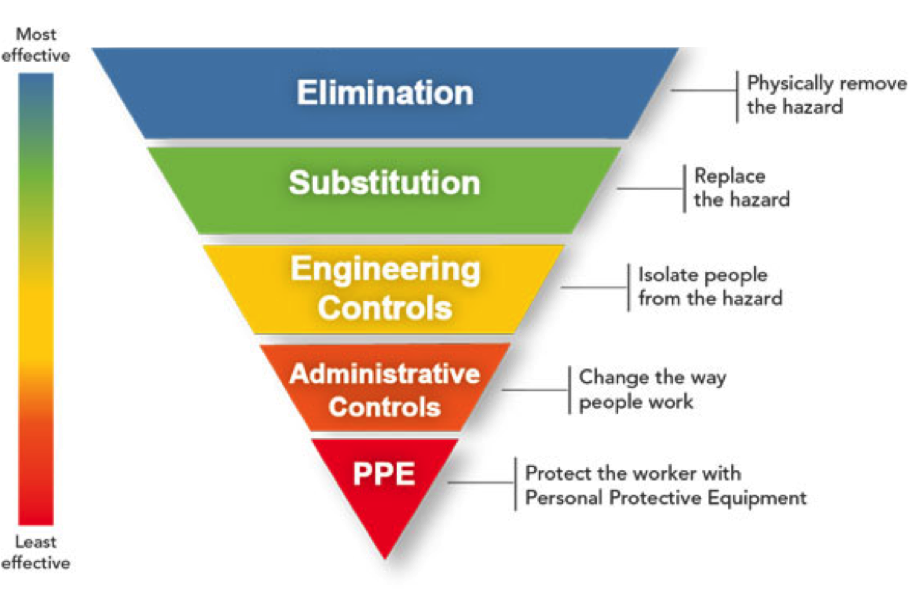

The primary areas of concern for explosions and dust emissions are enclosed vessels such as bins and hoppers, dust collection systems, and storage silos, and secondarily, enclosed conveyors such as bucket elevators. To protect these processes and equipment facilities use a hierarchy of controls, for effective dust management.

The Hierarchy of Controls

The hierarchy of controls includes Elimination, Substitution, Engineering Controls, Administrative Controls, and Personal Protective Equipment (PPE). The last three of these will be discussed further here.

Personal Protective Equipment

PPE, personal protective equipment, and gear are the easiest to apply to keep personnel safe from combustible wood dust and biomass dust. Prolonged or repeated exposure to fine dust from biomass, has an effect on employees’ health. Most of us know that when operating in areas where there are potential fire and explosion hazards, proper PPE must be worn. For example, safety glasses, hard hat, hearing protection, gloves and steel toed boots are the most common. When working around processes where there is potential for wood dust fires and explosions, you should also add FRC’s, fire resistant clothing. While this article focuses on combustible wood dust, this also applies to processes with biomass dust, flammable gasses, other flammable products, and hybrid mixtures.

Administrative Controls

Administrative controls such as housekeeping, hazard communication and management of change (MOC) are a primary level of prevention. For example, changing from softwoods to hardwoods, or adding a dryer to the process, necessitates hazard analysis, hazard communication, and management of change.

Engineering Controls

Engineering controls come in a variety of shapes and sizes. Several specific areas relevant to dust and dust control are discussed here. Area Classification for electrical controls; separation, isolation and segregation of dangerous processes from each other; and layered protection systems including dust collection, dust emissions, dust control solutions, fire prevention, and fire and explosion protection, are the main engineering controls discussed in this article.

Area Classification

Two Documents are used for the Classification of Combustible Dust and Hazardous Locations: NFPA 499 Recommended Practices for the Classification of Combustible Dusts and Hazardous Locations for Electrical Installations in Chemical Process Areas, and NFPA 70, Article 500 of the National Electrical Code (NEC).

Also, refer to NFPA 77 Recommended Practice on Static Electricity, NFPA 79 Electrical Standard for Industrial Machinery, and again NFPA 499 Recommended Practice for the Classification of Combustible Dusts and of Hazardous Locations for Electrical Installations in Chemical Process Areas.

Class/Division Hazardous Location

Hazardous locations are described as locations where electrical equipment might present an ignition hazard. Class II Hazards are locations where combustible or conductive dusts present (or may be present) in quantities sufficient to produce explosive or ignitable mixtures.

Division refers to the probability of hazardous materials and mixtures.

Division 1 has a high probability of producing an explosive or ignitable mixture due to it being present continuously, intermittently, or periodically from the equipment itself under normal operating conditions. Electrical equipment in these areas must meet the criteria for explosion proof rating.

Division 2 has a low probability of producing an explosive or ignitable mixture and is present only during abnormal conditions for a short period of time – such as a container failure or system breakdown. See NFPA 652 Standard on the Fundamentals of Combustible Dust requirement for a DHA Dust Hazard Analysis. NFPA 652 requires all such facilities to perform a dust hazard analysis and risk assessment for each process that handles or creates combustible fugitive dust.

Engineering Principles

An engineering principle outlined in NFPA 664 is to Isolate, segregate and separate the various hazardous parts of the process from each other. As an example, there is one design of hammer mill process that uses a plenum in between the mill and the dust collector, thus creating a bomb. It is preferable to have a choke in between like a screw conveyor or airlock, and to remove the dust collector to a remote location, outside the building, thus isolating a potential explosion or deflagration.

Another principle of design found in NFPA 664 is layered protection systems for fire prevention, fire protection, and explosion protection. NFPA 664 Chapter 8 applies to processes and systems such as mechanical conveyors, pneumatic conveyors, classifying, dust collection systems and dust control. Conveyors and ducts with a fire hazard are required to have fire prevention and/or fire protection.

Fire prevention is typically spark detection. Spark detection and extinguishing systems are a primary tool to prevent sparks from propagating into fires by detecting and suppressing sparks or embers in the incipient stage. Spark detection systems are typically applied to mechanical conveyors, pneumatic conveyors, and dust collection systems.

Fire protection is typical deluge and sprinkler systems. We may also utilize other types of hazard monitoring equipment such as bearing temperature, heat detection, spark, ember, flame, smoke, CO detection, and emissions monitoring, as well as other types of suppression, control and isolation devices. Interlocking machinery, conveyors, fire dumps, and proper sequencing of shutdowns are also critical engineering controls.

Explosion protection includes explosion venting or suppression as well as chemical or mechanical isolation to control and prevent a deflagration from transferring down or upstream, thus preventing catastrophic secondary explosions, and control dust and dust emissions.

Vessels and Venting

Vessels and dust collectors with a deflagration hazard are required to have explosion protection and isolation. Mechanical or chemical isolation of these vessels and collectors is also required. See NFPA 68 Standard on Explosion Protection by Deflagration Venting, and NFPA 69 Standard on Explosion Prevention Systems.

Explosion vents have to be engineered based on the explosive characteristics of the dust, thus dust testing is required. Venting needs to vent to a remote area away from buildings, machinery, and people. Blast radius areas should be defined. Bins inside the building can be vented outside provided the distance to the exterior wall is short enough. Alternately, indoor explosion vents, also called “flameless venting” can be utilized. These flameless vents use a mechanical or chemical flame barrier to suppress the flame front but still emit a pressure wave.

Where explosion venting cannot be used, chemical explosion protection and isolation must be used. Explosion protection systems consist of an optical and or pressure sensor, a control panel and chemical canisters strategically located on the vessel and connected ducting.

Conclusion

After implementing effective dust management above, you have now created layers of protection and dust control, based on the hierarchy of engineering controls, best practices, and applicable national codes and standards, for the biomass industry, biomass plants, and the food industry. You should also consult your insurance company as well as local codes and authorities having jurisdiction (AHJs).

So there you have it. A brief overview of how to protect your wood pellet and biomass operation from fires and explosions with dust control, and prolonged or repeated exposure to fine dust. With proper analysis, design, engineering and administrative controls, dust control solutions, training, and housekeeping, your plant can be made safe.

With these guidelines, you can reduce the probability of risk, control dust safely, as well as the severity of consequences, increase dust control solutions, maintaining safety and business continuity as well as a safe environment for employees and stakeholders, and safeguarding your reputation in the industry.

Questions?

Leave any questions in the comment box at the bottom of the page or reach out to Jeff directly at [email protected] to connect.

Free Download

Download a free copy of Jeff’s book (172 Pages, $17.97 on Amazon) using the link here: “The Ultimate Guide to Fire and Explosion Prevention – How to Keep your Plant from Blowing Up and Burning Down“

Jeffrey C. Nichols is Managing Partner at Industrial Fire Prevention, LLC and has been applying systems for the protection of equipment and personnel in processing industries since 1979. Mr. Nichols is a member of the NFPA 664 technical committee. Through his company, Jeff has been instrumental in bringing protection to many types of processes including drying, milling, grinding, and dust collection systems in industries handling combustible fugitive dust.

Reference Codes and Regulations

- The International Fire Code (IFC)

- The International Building Code (IBC)

- Local building codes

- National Fire Protection Association (NFPA), particularly the following codes:

- NFPA 68, Standard on Explosion Protection by Venting

- NFPA 69, Standard on Explosion Prevention Systems

- NFPA 70, National Electrical Code, (particularly the sections on area classifications)

- NFPA 77, Standard on Static Electricity

- NFPA 499, Recommended Practice for the Classification of Combustible Dusts and of Hazardous Locations for Electrical Installations

- NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids

- NFPA 652, Standard on the Fundamentals of Combustible Dust

- NFPA 664, Standard for the Prevention of Fire and Explosions in Wood Processing and Woodworking Facilities

Other Resources

Insurers such as FM Global have their own requirements. See the following FM Global Property Loss Prevention Data Sheets:

- FM 7-10, Wood Processing and Woodworking Facilities

- FM 7-11, Belt Conveyors

- FM 7-17, Explosion Protection Systems

- FM 7-73, Dust Collectors and Collection Systems

- FM 7-76, Prevention and Mitigation of Combustible Dust Explosions and Fire

- FM 7-78 Industrial Exhaust Systems

- FM 8-27, Storage of Wood Chips