Published November 5, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is Saw Dust Safety?

In the woodworking industry, sawdust is a familiar byproduct, but its safety risks are often underestimated. Fine sawdust particles can pose serious health and safety hazards, increase the risk of fires and explosions, and are subject to strict regulatory oversight. Proper sawdust management is not just a best practice—it’s essential for protecting health and safety in any woodworking environment. This article will walk you through everything woodworkers need to know about sawdust safety, from understanding its properties to implementing preventive and emergency measures.

Sawdust is a fine powder made from small wood particles produced when wood is cut, sanded, or ground. Every woodworking operation—whether from hand saws, power tools, or industrial equipment—generates sawdust. These tiny particles vary in size and shape based on the type of wood and the cutting process, and they can remain airborne, settling slowly over time.

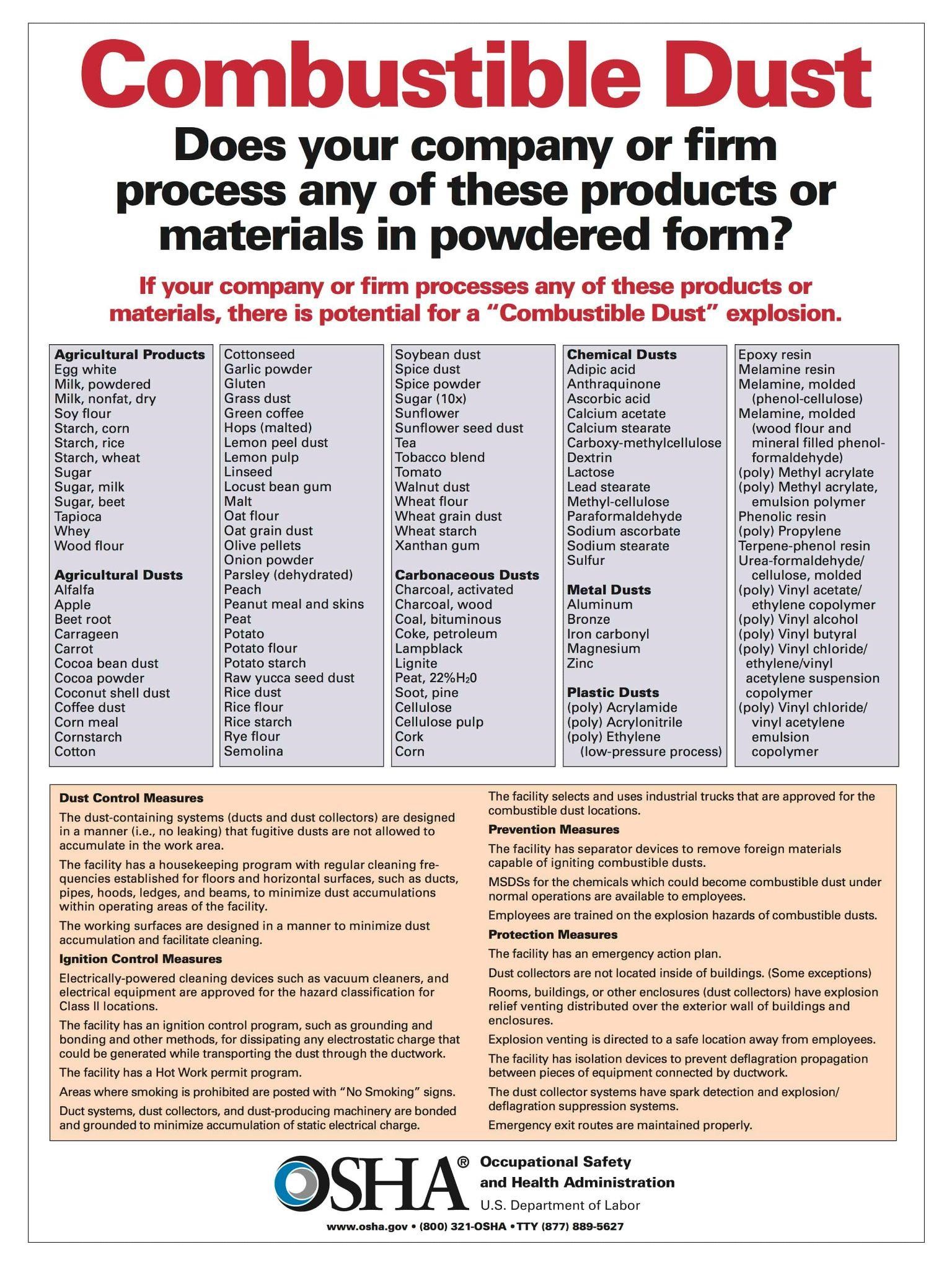

Is Saw Dust Considered Combustible Dust?

Yes, sawdust is considered a combustible dust hazard. Saw dust is lightweight and can easily become airborne. Chemically, sawdust is highly combustible, and in certain concentrations, it can even cause explosions. Different types of wood contain varying levels of oils and resins, which can add to the dust’s flammability or even cause allergic reactions in individuals exposed to it. Sawdust’s fibrous structure can also trap heat, making it susceptible to self-combustion if not stored or managed properly.

Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing.

Combustible dust may seem like an innocuous byproduct of industrial processes, but in certain conditions, it can pose severe risks, including dust explosions and fires. Understanding the formation, identification, and risks associated with combustible dust clouds is crucial for safety management in industries such as manufacturing, woodworking, and metalworking.

A combustible dust cloud consists of fine particles suspended in the air, when exposed to an ignition source, can lead to a fire or explosion. Combustible dust is created from a variety of materials, including organic substances like wood, and grain, as well as metals, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area.

Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as cutting, grinding, or transporting materials. These clouds can accumulate over time in hidden areas such as rafters, ductwork, or equipment, leading to dust explosions.

Health Risks Associated with Saw Dust

- Respiratory Issues: When inhaled, sawdust can damage the respiratory system. The tiny wood particles irritate the mucous membranes in the nose, throat, and lungs, leading to conditions like bronchitis, asthma, and chronic obstructive pulmonary disease (COPD). Prolonged exposure can lead to decreased lung function and even permanent lung damage. Woodworkers should prioritize respiratory protection and adequate dust collection systems to minimize inhalation risks.

-

Eye and Skin Irritation: Sawdust can irritate sensitive areas, especially the eyes and skin. Airborne particles can get into the eyes, causing discomfort, itching, and cause infection. Some wood types contain natural oils and chemicals that cause skin irritation, rashes, or allergies on contact. Wearing protective eyewear and clothing can help mitigate these issues.

-

Long-term Health Effects: Exposure to certain types of wood dust, particularly hardwood dust, has been linked to nasal cancer and other respiratory cancers. The International Agency for Research on Cancer (IARC) has classified wood dust as a Group 1 carcinogen, meaning there is enough evidence to consider it carcinogenic to humans. Understanding the long-term health risks of wood dust exposure reinforces the need for proper safety measures in the workplace.

Regulatory Standards and Guidelines for Saw Dust

The Occupational Safety and Health Administration, (OSHA), has guidelines aimed at minimizing the risks associated with combustible dust, including sawdust. OSHA mandates the use of dust control measures, including dust collection systems and personal protective equipment (PPE). Employers are also required to educate employees about the hazards and proper handling of combustible dust. The National Fire Protection Association, (NFPA), sets standards to prevent saw dust related fires and explosions. Complying with OSHA and NFPA standards is not only a legal obligation but also a key component of effective dust management. Both organizations provide detailed guidelines for managing combustible dust and preventing accidents.

How Compliance with Dust Management Regulations Reduces Risks:

- OSHA’s Combustible Dust National Emphasis Program (NEP): The Occupational Safety and Health Administration, (OSHA), provides Revised Combustible Dust National Emphasis Program guidelines to help industries manage combustible dust hazards.

-

OSHA local exhaust ventilation (LEV) systems for individual machines recommendations

-

NFPA 664, in particular, provides guidelines for the prevention of fires and explosions in woodworking facilities. NFPA standards advise on housekeeping, dust control, and proper ventilation.

- NFPA 652: Standard on the Fundamentals of Combustible Dust: Provides a general framework for managing combustible dust hazards in various industries.

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions: Focuses on the design, construction, and operation of facilities handling combustible dust.

-

National Institute for Occupational Safety and Health, (NIOSH), Control of Wood Dust From Table Saws

- Local Regulations for Compliance: Depending on the location, local governments may have additional requirements for sawdust management. Businesses should check with local authorities or industry-specific agencies to ensure compliance with all applicable regulations.

Managing Saw Dust in the Workplace

Sawdust, an inevitable byproduct of cutting, sanding, and shaping wood, poses significant health and safety risks if not properly controlled. Airborne sawdust can lead to respiratory issues, eye and skin irritation, and long-term health effects like cancer. Additionally, sawdust is highly combustible, and in certain concentrations, it can ignite and cause explosions. Proper management practices are crucial for maintaining a safe workplace. Recommendations for managing saw dust include:

- Dust Hazard Analysis: Dust Hazard Analysis (DHA) is a systematic approach to identifying and addressing dust-related risks in an industrial setting. A Dust Hazard Analysis involves evaluating the types of dust present, the potential ignition sources, and the likelihood of a dust explosion. Regular DHA is essential for keeping facilities compliant with NFPA 652 and other regulatory standards.

- Dust Collection Systems: Investing in a quality dust collection system is one of the most effective ways to manage sawdust. These systems capture dust directly at the source and transport it to a containment area, reducing airborne dust and preventing accumulation. Options include single-stage dust collectors for small shops and multi-stage cyclones for larger, industrial setups.

- Proper Ventilation: Effective ventilation dilutes airborne dust particles and lowers the risk of reaching explosive concentrations. Properly designed ventilation systems, especially in closed workshops, are crucial. This may include adding exhaust fans or air filtration units to further manage air quality. OSHA provides information on local exhaust ventilation (LEV) systems for individual machine recommendations

- Routine Cleaning Protocols: Regular cleaning prevents dust from accumulating on surfaces and equipment. This includes sweeping, vacuuming (with explosion-proof vacuums), and using compressed air safely to blow away dust in inaccessible areas. Establishing a routine cleaning protocol ensures dust levels remain manageable. Good housekeeping is one of the simplest yet most effective ways to prevent dust from accumulating to dangerous levels. A proper cleaning regimen ensures that dust doesn’t collect in areas that are hard to see or reach, which can become potential fire hazards.

- Vacuuming: Always opt for Combustible Dust Rated vacuums equipped with HEPA filters, as they prevent dust from being reintroduced into the air. Avoid sweeping and Compressed Air: Sweeping and compressed air can disperse dust into the air, causing a dust cloud, increasing inhalation risks and the potential for an explosion.

- Dust Control Fans: HazLoc and UL Certified Dust Control Fans, use high-velocity airflow to create an air curtain and air barrier, preventing them from settling and accumulating.

Saw Dust and Personal Protective Equipment (PPE)

- Respiratory Protection: Respirators and masks rated for dust filtration, such as N95 or P100 masks, are essential for woodworkers. These protect against fine sawdust particles that can penetrate deep into the lungs.

- Protective Clothing: Gloves, long-sleeved shirts, and full-coverage eye protection are recommended to protect the skin and eyes from irritation. Some woodworkers may also wear coveralls to limit direct contact with dust on their regular clothes, reducing skin irritation.

- Training and Signage: Employers should provide training on the proper use of PPE and post signage around the workshop to remind employees of the risks associated with sawdust exposure. Proper usage of PPE significantly reduces health risks.

Emergency Response and Preparedness with Saw Dust Safety Incidents

Emergency Planning: Woodworking facilities should have a well-developed emergency response plan for sawdust-related incidents, including fires and explosions. This plan should specify evacuation routes, firefighting procedures, and roles for employees during an emergency.

First Aid Measures: In the event of exposure, it’s crucial to have a basic first-aid protocol. Eye flush stations should be available for those who get dust in their eyes, and respiratory emergencies should be managed with oxygen if available or by seeking immediate medical attention.

Regular Drills and Training: To maintain preparedness, facilities should conduct regular fire drills and safety training sessions. This reinforces the steps employees should take in an emergency and ensures everyone knows how to respond effectively.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), for Saw Dust Safety

Recent advancements in Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) are significantly transforming fire detection and prevention, especially in industries managing combustible sawdust. With AI and ML, systems can now analyze vast amounts of data from various sensors in real time, detecting patterns that indicate potential hazards. For instance, IoT-enabled sensors can monitor dust particle concentration, temperature, and humidity levels, which are critical factors in preventing dust-related explosions. AI algorithms can interpret this data continuously, identifying unusual trends or thresholds that suggest elevated risks and triggering preemptive safety measures, such as activating ventilation or adjusting dust collection systems. This approach offers a proactive layer of protection, allowing facility managers to address hazards before they escalate.

Additionally, ML-driven predictive maintenance is playing an increasingly vital role in sawdust safety. By learning from historical data, ML algorithms can predict when dust collection systems or ventilation equipment might fail, alerting maintenance teams before issues arise. This helps to avoid unexpected downtimes and reduces the likelihood of dangerous dust accumulations due to equipment malfunctions. AI-powered vision systems are also enhancing safety by visually monitoring for dust levels, spark detection, and other signs of potential fire hazards. Together, these technologies are empowering industries to create safer environments by minimizing human error, improving response times, and optimizing equipment performance—all of which are critical steps in reducing the risks associated with combustible saw dust.

Conclusion

Sawdust management is a critical safety concern in woodworking environments, from hobbyist workshops to large-scale industrial settings. By understanding sawdust’s properties and risks, and by implementing robust safety measures, woodworkers can protect themselves and their workplaces from potentially severe health and safety hazards. Following OSHA and NFPA standards, investing in proper dust management systems, and using PPE are all essential practices. By staying vigilant and fostering a safety-conscious workplace, woodworkers can ensure a healthier, safer environment for all.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Saw Dust Safety and Combustible Dust Management, with a Podcast. Click on the latest Podcast Link: Challenges With Educational Wood Shop Dust Collection Systems

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.