Published October 8, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is the Giacomelli’s Bakery Flour Dust Explosion of 1785?

Giacomelli’s Bakery, located in Turin, Italy, was a well-established bakery during the late 18th century. Like many other bakeries at the time, the operation used large quantities of flour daily, and flour dust naturally accumulated throughout the facility. However, the tragic event that unfolded on December 14th, 1785 was a flour dust explosion that would become one of the earliest recorded instances of such a disaster.

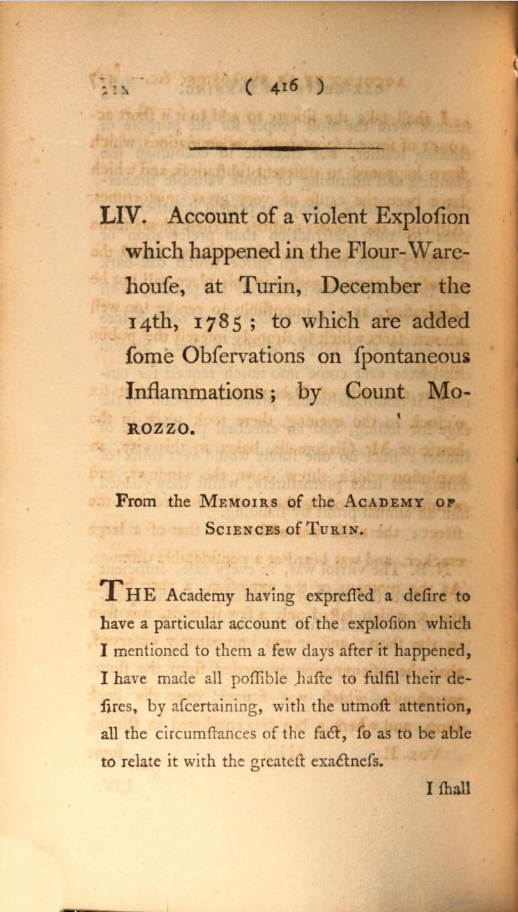

According to historical accounts from The Repertory of Arts and Manufactures, Volume 2, Publisher G. & T. Wilkie., 1795 Original, from the New York Public Library, Digitized Aug 19, 2011, Count Carlo Ludovico Morozzo di Bianzè investigated and recorded December 14th, 1785. The flour dust explosion occurred when one worker, was pouring flour into a bolter, from a second floor level of the bakery. (A bolter, similar to a sieve or sifter, is a device used in a bakery that separates flour into finer and coarser portions, with screens with different hole sizes.) Some of the finer flour spilled out of the bolter. The spilled flour created a flour dust cloud in the air and reacted with an ignition source, a candlelit lamp on the lower level, and ignited the suspended flour dust cloud. The dust explosion devastated the bakery, injuring two workers, and causing significant damage to the surrounding area. The immediate aftermath was shock and confusion, as there was little understanding at the time of the science behind such an explosion.

This event is historically significant because it marked a turning point in recognizing the dangers of airborne dust in industrial settings. The explosion at Giacomelli’s Bakery would prompt an investigation and eventually contribute to the development of early safety measures to prevent similar disasters.

What is a Flour Dust Explosion

Dust explosions have been a significant industrial hazard throughout history, often with devastating consequences. These flour dust explosions are caused by the rapid combustion of airborne dust particles, which can create violent pressure waves and lead to catastrophic destruction. One of the first recorded instances of such a flour dust explosion event occurred at Giacomelli’s Bakery in 1785, a tragedy that not only shocked its time but also laid the groundwork for understanding the dangers of combustible dust.

The Giacomelli’s Bakery explosion holds a special place in the history of industrial safety because it serves as one of the earliest examples of a flour dust explosion. By studying events like this, we gain valuable insights into how dust explosions occur and how to prevent them, making it essential to revisit historical events to inform and shape modern safety protocols.

The Role of Count Morozzo in the Aftermath

Following the explosion, Count Carlo Ludovico Morozzo di Bianzè, a scholar and investigator, played a crucial role in understanding the mechanics behind the tragedy. He was among the first to investigate the relationship between flour dust and explosions, and his work laid the foundation for future studies on combustible dust hazards.

Count Morozzo’s findings helped to highlight the dangers of flour dust in confined spaces, and he recommended more attention be paid to cleanliness and dust management in bakeries and mills. His work was a precursor to the more sophisticated safety practices that would develop in the following centuries. The investigation conducted by Morozzo helped shed light on the importance of managing airborne dust, particularly in industries that work with fine, combustible powders.

Flour Dust as Combustible Dust

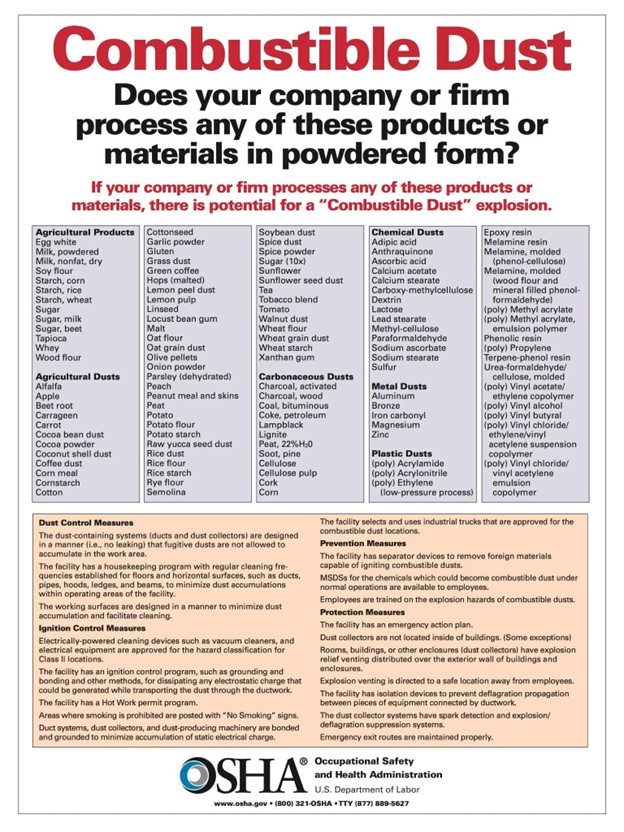

Combustible dust is created from a variety of materials, including organic substances like grain, metals, wood, plastics, and chemicals. For dust to become a significant hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area. Combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing.

Combustible flour dust may seem like an innocuous byproduct of industrial processes, but in certain conditions, it can pose severe risks, including dust explosions and fires. Understanding the formation, identification, and risks associated with combustible dust clouds is crucial for safety management in industries such as agriculture, farming, manufacturing, woodworking, and metalworking.

Dust clouds form when fine particulate matter becomes airborne, often due to industrial activities such as pouring, sifting, cutting, grinding, or transporting materials. These clouds can accumulate over time in hidden areas such as rafters, ductwork, or equipment, leading to dangerous buildup.

Managing combustible dust is identifying where it tends to accumulate. Dust can settle on surfaces such as floors, beams, ledges, and machinery, making it essential to inspect these areas regularly.

Key strategies to identify accumulation points include:

- Perform a Dust Hazard Analysis

- Regular visual inspections.

- Inspect confined spaces, overhead piping, beams, and suspended ceilings.

- Reviewing areas of low airflow, where dust may collect.

- Monitoring facility changes that could increase dust exposure (e.g., changes in production processes).

The Year 1785: Context of the Explosion

The explosion at Giacomelli’s Bakery occurred during a period of political and economic change in Italy. The industrial revolution was slowly transforming Europe, bringing new technologies and processes that increased production but also introduced new hazards. In 1785, Italy was not yet fully industrialized, but many small-scale bakeries, mills, and factories were springing up to meet the growing demand for goods.

Safety practices at the time were rudimentary at best. Workers were often unaware of the dangers associated with dust accumulation, and facilities lacked modern safety measures such as ventilation, dust extraction systems, and explosion venting equipment. This lack of awareness and preparedness was common across many industries, leading to frequent accidents.

Key Risks Associated with Combustible Dust Clouds

Combustible dust explosions occur when a dust cloud encounters an ignition source in a confined or semi-confined space, leading to rapid combustion. The five elements required for a dust explosion are:

- Combustible dust.

- Dispersion of dust particles into the air.

- A confined space.

- Oxygen.

- An ignition source.

Ignition Sources and Dust Cloud Explosion Potential

Identifying and eliminating ignition sources is a critical step in preventing dust explosions. Common ignition sources in industrial settings include:

- Hot surfaces: Machinery and equipment that generate heat can ignite dust clouds.

- Electrical components: Lightbulbs, faulty wiring, sparks from switches, or static discharge can ignite combustible dust.

- Open flames: Candles, lanterns, cigarettes, lighters, Welding and Disk Grinder Sparks, cutting torches, and other open flames are significant risks in areas with high dust levels.

Dust explosions are classified as either primary or secondary. A primary dust explosion occurs when dust suspended in the air is ignited, often by a spark or flame. Secondary dust explosions can follow, triggered by the dust stirred up by the initial blast. These secondary explosions are typically more devastating as they can propagate rapidly throughout an entire facility.

Preventing dust explosions requires stringent control of both dust accumulation and ignition sources.

Accumulated Dust as a Hidden Danger

One of the key contributors to dust explosions is the accumulation of combustible dust on surfaces such as beams, floors, and machinery. In bakeries like Giacomelli’s, flour dust would accumulate over time, forming a layer of powder that could easily become airborne. If not properly cleaned, these dust layers pose a significant risk.

When an initial explosion (primary explosion) occurs, it can disturb accumulated dust, creating secondary explosions that are often more destructive than the first. This danger emphasizes the importance of regular safe cleaning and safe dust control in industrial settings.

Fugitive Dust and Its Contribution to Explosions

Fugitive dust refers to dust particles that escape from machinery or processes and become suspended in the air or settle on surfaces. In industrial settings, fugitive dust can come from many sources, including grinding, sifting, and transporting materials. In bakeries, the handling of flour generates a constant source of fugitive dust.

At Giacomelli’s Bakery, fugitive dust likely accumulated over time, and when it became airborne due to a disturbance, it created an explosive atmosphere. Modern safety practices include the use of dust collection systems and regular cleaning to prevent the buildup of fugitive dust.

Lessons Learned from the Giacomelli’s Bakery Explosion

The tragic explosion at Giacomelli’s Bakery in 1785 serves as an early lesson in the importance of managing combustible dust risks. The key lessons from this historical event include:

- The necessity of understanding how everyday materials like flour can become explosive under the right conditions.

- The importance of regular cleaning and dust management in facilities handling combustible materials.

- The need for recognizing and controlling ignition sources in areas where dust is present.

Modern industries have benefitted greatly from the lessons learned from this event, leading to the development of comprehensive safety standards aimed at reducing the risk of dust explosions.

Legal and Regulatory Framework to Prevent Dust Explosions

The Occupational Safety and Health Administration, (OSHA), provides Revised Combustible Dust National Emphasis Program guidelines to help industries manage combustible dust hazards. OSHA’s General Duty Clause mandates that employers provide a workplace free of recognized hazards, which includes combustible dust explosions. OSHA also conducts inspections and issues citations for non-compliance with safety standards related to combustible dust.

The National Fire Protection Association (NFPA) has developed specific standards that address combustible dust risks. Two key standards include:

- NFPA 652: Standard on the Fundamentals of Combustible Dust: Provides a general framework for managing combustible dust hazards in various industries.

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions: Focuses on the design, construction, and operation of facilities handling combustible dust.

Compliance with these regulations is critical for minimizing risks and ensuring the safety of workers and facilities.

Technology Advances, with the Integration of Artificial Intelligence, (AI), and Machine Learning, (ML), and Preventing Flour Dust Explosions in Bakeries

Recent technological advancements in Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) are revolutionizing fire detection and prevention strategies, especially concerning combustible dust accumulation and dust clouds. AI-powered systems now integrate with dust monitors, which measure airborne dust particles in real time. This allows for an immediate response when high dust levels are detected, minimizing the risk of an explosion. The combination of IoT devices continuously monitoring environmental factors such as temperature, dust particle concentration, and air quality provides real-time alerts to operators and automated safety systems, further enhancing workplace safety. Additionally, dust sampling—collecting and analyzing dust samples to assess particle size, concentration, and flammability—helps create detailed risk profiles, improving the precision of AI-driven early warning systems.

Machine Learning (ML) algorithms play a crucial role by analyzing data patterns from these monitoring tools to predict potential hazards. These algorithms can distinguish between normal operational dust levels and dangerous accumulations, reducing false alarms and enabling a more accurate hazard response. Thermography, another key advancement, aids in detecting heat sources that could ignite dust clouds, further preventing fire incidents. Together, AI, IoT, dust monitors, dust sampling, and thermography create a comprehensive fire detection and prevention system that significantly improves safety protocols in industries handling combustible dust. This integrated approach ensures early detection, quick response, and overall enhanced protection against potential dust explosions or fires.

Conclusion

The Giacomelli’s Bakery explosion in 1785 was a pivotal moment in the history of industrial safety, highlighting the dangerous potential of airborne flour dust. By examining this historical event, we can better understand the risks associated with combustible dust and take proactive steps to prevent similar disasters in modern industries. The importance of proper dust management, identifying ignition sources, and implementing safety protocols cannot be overstated, as these measures are crucial to protecting both workers and facilities.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Flour Dust Explosions, with a Podcast. Click on the latest Podcast Links: Incident Update – 2021 Flour Dust Explosion in Savannah, Georgia

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.