Updated December 19, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is a Combustible Dust Cloud?

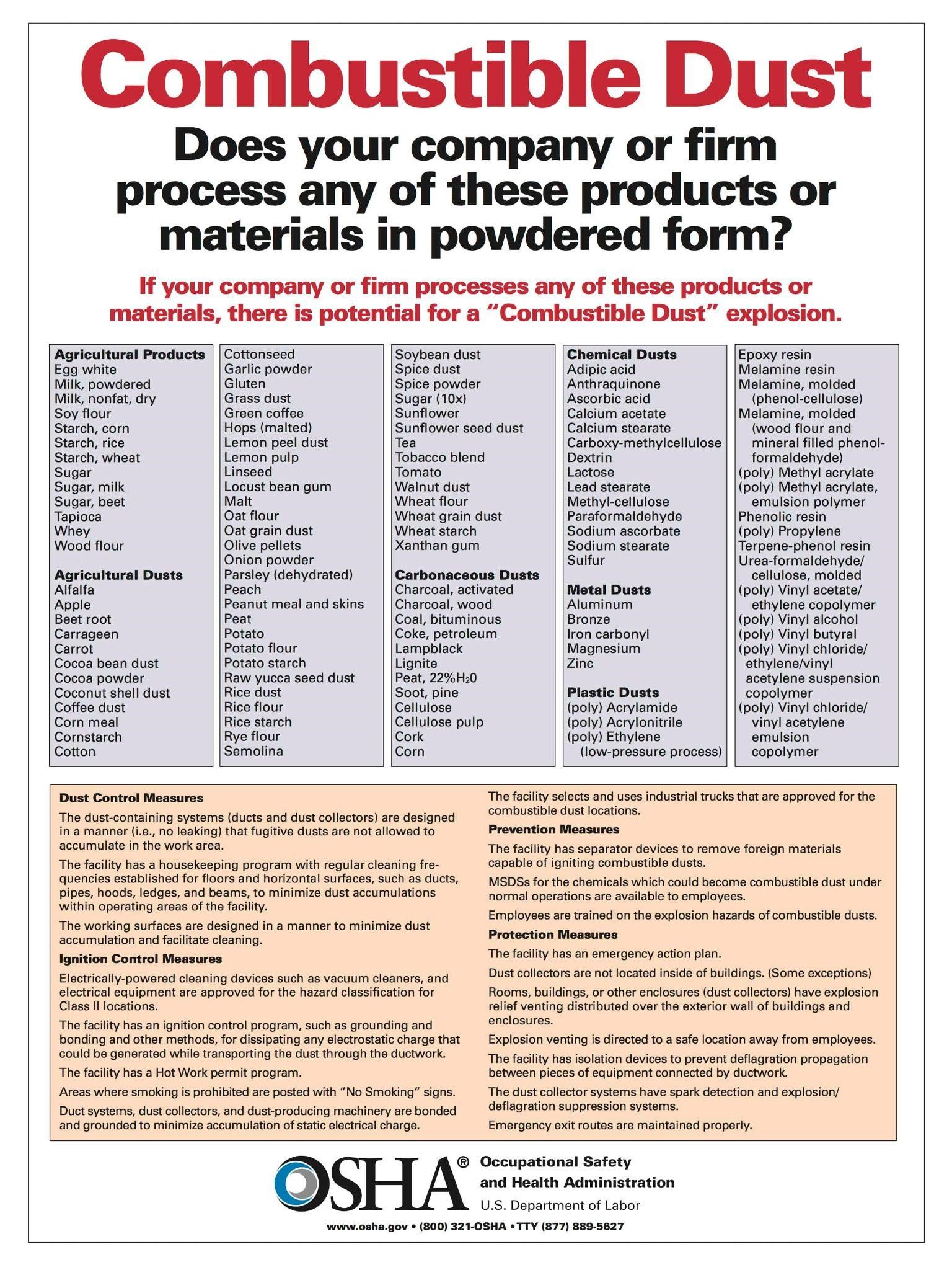

A combustible dust cloud consists of fine particles suspended in the air, when exposed to an ignition source, can lead to a fire or explosion. Combustible dust is created from a variety of materials, including organic substances like wood, and grain, as well as metals, plastics, coal dust, and chemicals. For dust to become a significant explosion hazard, the particles must be the right size, and there must be enough oxygen and a confined space or enclosed area.

Explosive clouds form when fine particulate matter becomes airborne, often due to industrial activities such as cutting, grinding, or transporting materials. These clouds as combustible dust, can accumulate over time in hidden areas such as rafters, ductwork, dust collectors, or production equipment, leading to dangerous buildup, explosion hazard, and combustible dust explosions.

According to the Occupational Safety and Health Administration, (OSHA), combustible dust refers to finely divided solid particles that are prone to ignition and ignition sources such as static electricity, when suspended in the air. These combustible dust particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing, creating possible combustible dust explosions.

Combustible dust may seem like an innocuous byproduct of industrial processes, but in certain conditions, it can pose severe risks, including dust explosions and catch fire and create a flash fire. Understanding the formation, identification, chemical composition, and risks associated with explosive clouds and combustible dust is crucial for safety management in industries such as manufacturing, woodworking, and metalworking.

Several Industries are Particularly Vulnerable to Combustible Dust Hazards, Including:

- Woodworking and Furniture Manufacturing: Sawdust, wood dust, and wood particles can become highly combustible when suspended in the air.

- Grain Handling and Food Processing: Grain dust is one of the most common culprits in explosions due to its fine particle size.

- Metalworking: Metal dust from metals like aluminum and magnesium can ignite easily when exposed to a spark or heat, and cause a combustible dust explosion. Metal dust like zirconium has the highest Kst Value for a very strong explosion and secondary dust explosions.

- Chemical Manufacturing: Fine powders used in chemical processes can become airborne and suspended in air, and cause a combustible dust explosion.

Given the widespread impact across multiple industries, understanding “what is a combustible dust cloud” is essential to ensuring workplace safety, from explosions.

Identification of Explosive Clouds and Recognizing Accumulated Dust

One of the key challenges in managing combustible dust is identifying where combustible dust explosions happen, and where dust tends to accumulate. Dust can settle on surfaces such as floors, beams, ledges, and machinery, making it essential to inspect these areas regularly.

Key strategies to identify accumulation points include:

- Perform a Dust Hazard Analysis

- Regular visual inspections.

- Inspect confined spaces, overhead piping, beams, and suspended ceilings.

- Reviewing areas of low airflow, where dust may collect.

- Monitoring facility changes that could increase dust exposure (e.g., changes in production processes).

Good housekeeping practices are the first line of defense in controlling combustible dust levels. Establishing a consistent cleaning schedule to remove settled dust is critical to minimizing the risk of a cloud forming.

Detecting Fugitive Dust

Fugitive dust is the term used for dust that escapes from its intended containment system during production processes. Even with proper filtration and dust collection systems in place, it’s important to monitor for dust that can escape through cracks in equipment, ventilation leaks, or transfer points.

Strategies for detecting fugitive dust include:

- Perform a Dust Hazard Analysis

- Regular air monitoring to detect dust levels in the environment.

- Inspection of containment systems and ventilation systems for any signs of wear or leaks.

- Using dust sampling and monitoring devices.

Tools and Techniques for Dust Measurement

To effectively manage dust, industries use a variety of tools to measure combustible dust levels and perform a risk assessment. The most common methods include:

- Dust Monitors: These devices measure airborne particles in real time, allowing for immediate response to high levels.

- Dust Sampling: Collecting and analyzing combustible dust samples helps in understanding particle size, concentration, and flammability.

- Thermography: Detects heat sources that could ignite explosive clouds.

By identifying accumulated and fugitive dust and regularly measuring dust levels, companies can maintain a safer working environment and prevent the formation of hazardous, explosive clouds.

Key Risks Associated with Explosive Clouds

Dust explosions occur when a cloud encounters an ignition source in a confined or semi-confined space, leading to rapid combustion, and can catch fire and create a flash fire. The five elements of the dust explosion pentagon required for a dust explosion are:

- Combustible dust.

- Dispersion of dust particles into the air.

- A confined space.

- Oxygen.

- An ignition source.

When these conditions are met, with the dust explosion pentagon, even a small spark can cause an explosion hazard and devastating explosion. Historical events such as the 2008 explosion at a sugar refinery in Georgia, which killed 14 people and injured dozens, demonstrate the catastrophic potential of dust explosions. This event is a prime example of the dangers posed by accumulated dust and emphasizes the importance of proper dust management and monitoring.

Ignition Sources and Cloud Explosion Potential

Identifying and eliminating ignition sources is a critical step in preventing an explosion hazard

and dust explosions. Common ignition sources in industrial settings include:

- Hot surfaces: Machinery and equipment that generate heat can ignite explosive clouds.

- Electrical components: Faulty wiring, sparks from switches, or static discharge can ignite combustible dust.

- Open flames: Welders, cutting torches, and other open flames are significant risks in areas with high combustible dust levels.

Dust explosions are classified as either primary or secondary. A primary dust explosion occurs when dust suspended in the air is ignited, often by a spark or flame. Secondary dust explosions can follow, triggered by the dust stirred up by the initial blast. These secondary explosions are typically more devastating as they can propagate rapidly throughout an entire facility.

Preventing dust explosions requires stringent control of both dust accumulation and ignition sources.

Engineering Controls to Prevent Explosive Clouds

Effective dust control begins with the right engineering solutions. These include:

- Dust collection systems: These are designed to capture airborne dust at the source, preventing it from spreading through the facility.

- Ventilation: Proper ventilation helps dissipate explosive clouds and reduces the chances of explosive concentrations.

- Explosion venting and suppression systems: In high-risk areas, installing explosion venting systems allows pressure from an explosion to be released safely.

Administrative Controls to Prevent Explosive Clouds

Implementing administrative controls ensures that employees understand the risks of combustible dust and follow proper safety procedures. These controls may include:

- Dust hazard training: Employees should be educated on identifying dust risks and proper procedures for handling materials.

- Routine inspections and maintenance: Regular inspections of equipment, dust collection systems, and areas prone to dust accumulation are necessary.

- Clear procedures for handling ignition sources: Workers should be trained to avoid creating sparks or open flames in areas where dust accumulation may occur.

Personal Protective Equipment (PPE) and Explosive Clouds

In addition to engineering and administrative controls, personal protective equipment (PPE) is essential for worker safety in high-risk environments. Workers should wear:

- Respirators to protect against inhalation of fine dust particles.

- Flame-resistant clothing to protect against burns in case of an explosion.

- Eye protection and hearing protection in environments where explosions are a possibility.

Legal and Regulatory Framework to Prevent Explosive Clouds

The Occupational Safety and Health Administration, (OSHA), provides Revised Combustible Dust National Emphasis Program guidelines to help industries manage dust hazards. OSHA’s General Duty Clause mandates that employers provide a workplace free of recognized hazards, which includes combustible dust explosions. OSHA also conducts inspections and issues citations for non-compliance with safety standards related to combustible dust.

The National Fire Protection Association (NFPA) has developed specific standards that address combustible dust risks. Two key standards include:

- NFPA 652: Standard on the Fundamentals of Combustible Dust: Provides a general framework for managing dust hazards in various industries.

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions: Focuses on the design, construction, and operation of facilities handling combustible dust.

Compliance with these regulations is critical for minimizing risks and ensuring the safety of workers and facilities.

Technology Advances, with the Integration of Artificial Intelligence, (AI), Machine Learning, (ML), and Preventing Explosive Clouds

Recent technological advancements in Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) are revolutionizing fire detection and prevention strategies, especially concerning explosive clouds. AI-powered systems now integrate with dust monitors, which measure airborne dust particles in real time. This allows for an immediate response when high dust levels are detected, minimizing the risk of an explosion. The combination of IoT devices continuously monitoring environmental factors such as temperature, dust particle concentration, and air quality provides real-time alerts to operators and automated safety systems, further enhancing workplace safety. Additionally, dust sampling—collecting and analyzing dust samples to assess particle size, concentration, and flammability—helps create detailed risk profiles, improving the precision of AI-driven early warning systems.

Machine Learning (ML) algorithms play a crucial role by analyzing data patterns from these monitoring tools to predict potential hazards. These algorithms can distinguish between normal operational dust levels and dangerous accumulations, reducing false alarms and enabling a more accurate hazard response. Thermography, another key advancement, aids in detecting heat sources that could ignite clouds, further preventing fire incidents. Together, AI, IoT, dust monitors, dust sampling, and thermography create a comprehensive fire detection and prevention system that significantly improves safety protocols in industries handling combustible dust. This integrated approach ensures early detection, quick response to prevent combustible dust explosion, combustible dust incidents, and overall enhanced protection against potential explosions or fires.

Conclusion

Understanding the basics of clouds is essential for anyone working in industries where dust accumulation and ignition are possible with dust present. By identifying the sources of dust, recognizing the risks, and implementing engineering, administrative, and PPE controls, businesses can reduce the likelihood of a catastrophic dust explosion and combustible dust incidents.

Remaining compliant with OSHA and NFPA standards is also key to maintaining a safe working environment. Continuous education and regular safety updates should be part of every organization’s strategy to manage combustible dust hazards effectively.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Explosive Clouds, with a Podcast. Click on the latest Podcast Links: Metal Dust Explosion Loss History, Severity & Practical Considerations

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.