Update October 21, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is a Class B Fire?

According to the NFPA, a Class B fire is flammable liquids (burn at room temperature) and combustible liquids (require heat to ignite). Petroleum greases, tars, oils, oil-based paints, solvents, lacquers, alcohols, and flammable gases. High fire hazard; water may not extinguish. Extinguish by creating a barrier between the fuel and the oxygen, such as a layer of foam. This Class B fire category covers substances like gasoline, oil, alcohol, propane, butane, ether, grease, and solvents, commonly found in industrial and residential environments. The volatility of these materials makes Class B fires particularly dangerous, as they can ignite easily and spread rapidly if not controlled promptly.

The primary characteristic of Class B fires is that they stem from liquid or gaseous fuels, in contrast to solid materials like wood or paper. Once a Class B fire ignites, it is difficult to contain without specialized firefighting equipment designed for liquid and gas-based fires, which are best extinguished by smothering.

The Difference Between Class B and Other Fire Classes

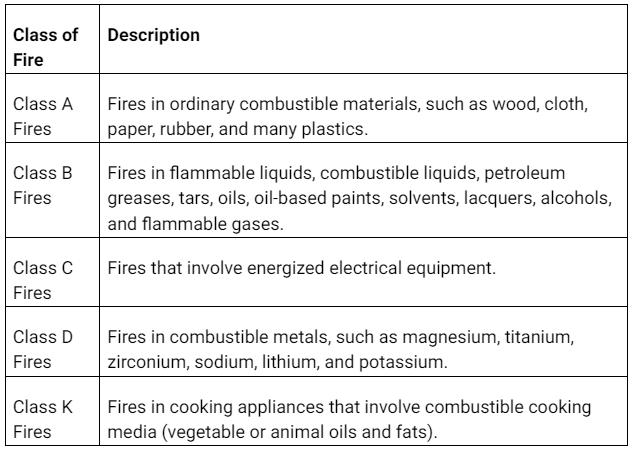

Fires are classified based on the type of fuel involved, and each class requires a different method of extinguishment:

- Class A fires: involve ordinary combustible materials like wood, paper, and fabric.

- Class C fires: are electrical fires, involving energized electrical equipment.

- Class D fires: are fueled by combustible metals such as magnesium or titanium.

- Class K fires: relate to cooking oils and fats, typically in commercial kitchens.

Class B fires differ in that they are fueled by liquids and gases, making them more likely to spread quickly due to the properties of the substances involved. Additionally, water-based methods that are effective on Class A fires may be ineffective or dangerous when applied to Class B fires, as water can spread flammable liquids or cause chemical reactions. Class A fire extinguishers use water, while Class B fire extinguishers use dry chemicals (foam or powder).

Common Causes of Class B Fires

Flammable liquids such as gasoline, diesel, alcohol, and solvents primarily contribute to Class B fires. These liquids have a low flashpoint, meaning they can ignite at relatively low temperatures.

Common Scenarios Where Flammable Liquids May Cause Class B Fires Include:

- Refueling vehicles at gas stations, where gasoline spills or vapor accumulation can ignite.

- Handling chemicals in industrial or laboratory settings, where open flames or sparks may lead to combustion.

- Improper storage of fuels in garages or basements, where leaks and fumes can create fire hazards.

Class B Flammable Gases

Flammable gases, such as propane, butane, and methane, are highly combustible and are often used in residential heating, cooking, or industrial processes.

Common scenarios for gas-related Class B fires include:

- Gas leaks in homes or industrial settings due to faulty appliances or damaged gas lines.

- Improper storage of propane or butane canisters, which, if exposed to high heat or puncture, can lead to explosions.

- Industrial processes that utilize gases for energy or manufacturing, where accidental releases or malfunctions can ignite fires.

Class B Fire Risk Factors

Certain industries face a higher risk of Class B fires due to the frequent handling of flammable liquids and gases. These industries include:

- Oil refineries, where crude oil and its derivatives are processed, create a constant risk of a fire.

- Chemical plants, store and use large quantities of volatile chemicals.

- Automotive industries, where fuel and oil are frequently handled.

Case Studies of Class B Fire Incidents

According to Wikipedia, the 2005 Buncefield Oil Depot fire in the UK, involved a massive explosion caused by fuel vapors igniting. Another incident is the San Bruno pipeline explosion in California (2010), which was caused by a gas pipeline rupture and led to significant loss of life and property damage.

These incidents highlight the volatility of liquids and gases and the severe consequences when safety protocols are not strictly followed.

Dangers and Challenges of Class B Fires

- Rapid Spread and Intensity: Class B fires are known for their ability to spread rapidly due to the flammable nature of the liquids and gases involved. A small spark or open flame can lead to explosive results, especially in enclosed spaces where vapors can accumulate. The intense heat and flames can also cause secondary fires and explosions, posing significant risks to firefighters and nearby structures.

- Health and Environmental Risks: Burning flammable liquids and gases often releases toxic fumes such as carbon monoxide and other harmful pollutants. Prolonged exposure to these fumes can lead to respiratory issues or even death. From an environmental standpoint, water and soil contamination can occur when chemicals from fires seep into the ground, causing long-term ecological damage.

- Difficulties in Extinguishing Class B Fires: The nature of flammable liquids and gases presents unique challenges when extinguishing Class B fires. Traditional water-based extinguishing methods are generally ineffective, as water can spread the burning liquid or even cause the fire to intensify. Using the wrong extinguishing agent can exacerbate the problem, making it crucial to select the correct firefighting equipment.

Extinguishing Techniques for Class B Fires

To effectively combat Class B fires, the following types of fire extinguishers are recommended:

- CO2 Extinguishers: Carbon dioxide works by displacing oxygen and smothering the flames.

- Foam Extinguishers: Foam creates a barrier over the surface of the liquid, preventing the fire from accessing oxygen.

- Dry Chemical Extinguishers: These extinguishers use a chemical powder to interrupt the chemical reaction within the fire.

Each extinguisher has specific advantages depending on the nature of the fire, and it’s important to select the appropriate one.

Step-by-Step Extinguishing Process for Class B Fires

When using a fire extinguisher for a Class B fire, the National Fire Protection Association, (NFPA), recommends using the PASS technique to extinguish fire with a fire extinguisher:

1. Assess the fire: Ensure you have the correct extinguisher and the fire is manageable.

2. Pull the pin: Unlock the extinguisher by pulling the pin.

3. Aim at the base: Direct the nozzle at the base of the fire, not the flames.

4. Squeeze the handle: Release the extinguishing agent.

5. Sweep side to side: Use a sweeping motion until the fire is fully extinguished.

Additional Tips for Using a Class B Fire Extinguisher:

- Before approaching a fire, test the extinguisher to make sure it works.

- Have a reputable contractor inspect your fire extinguishers annually and tag them with the inspection date.

- Look around to Prevent electrical shock from circuit breakers and outlets

- Keep your face away from the top of the extinguisher.

- Some extinguishers may require you to aim up instead of sweeping across the base of the fire.

- Continue to watch the area for a few minutes after putting out the fire in case it re-ignites.

Fire Suppression Systems for Industrial Settings

For high-risk industrial settings, automatic fire suppression systems are crucial. These systems include:

- Foam-based systems: Ideal for areas where large quantities of flammable liquids are present.

- Gas suppression systems: These systems release inert gases or chemicals to suppress fires by reducing oxygen levels or interrupting chemical reactions.

Prevention and Control Measures For Class B Fires

Preventing Class B fires begins with the proper storage and handling of flammable materials. Ensure all containers are sealed properly, and that liquids and gases are stored away from heat sources.

Regular maintenance and inspection of fire suppression equipment are vital for ensuring functionality when needed.

A fire watch refers to a temporary measure implemented to monitor and prevent fires in areas where there is a higher risk of fire incidents, often due to construction, maintenance, or hot work activities (such as welding or cutting). A designated person or team conducts continuous surveillance to identify potential fire hazards, ensure that fire safety measures are in place, and respond immediately if a fire breaks out. Fire watches are particularly necessary when fire protection systems like sprinklers are deactivated or when there is a higher chance of ignition.

A hot work permit is a formal document issued by a regulatory authority or organization that authorizes specific activities that pose a fire risk, such as hot work (welding, cutting, etc.), under strict safety protocols. The permit outlines the safety measures that must be taken during the work and specifies the requirement for a fire watch in areas where there is potential for fire hazards. This permit ensures that personnel understand the risks, and fire classes, use the correct fire extinguishers, have a trained fire watch on-site, and follow prescribed safety guidelines.

Special Considerations for Combustible Dust and Class B Fires

In industrial settings, combustible dust can act as a secondary hazard in Class B fire situations. For example, dust particles can ignite in the presence of a flammable gas fire, leading to dust explosions.

Case Study: Combined Class B and Combustible Dust Incident

According to OSHA, a National Institute for Occupational Safety and Health (NIOSH) report, a fire occurred in a coal bin that fed a boiler, in South Dakota, in 2011. The explosion may have involved combustible dust, flammable gases, steam, or a combination of these factors.

Fine particles, such as combustible dust, can easily ignite and lead to dust explosions, which are often catastrophic. These combustible dust explosions occur when dust accumulates and becomes airborne, creating a dust cloud that can be ignited by heat sources, such as machinery, electrical sources, sparks, friction, or static electricity.

Training and Preparedness for Class B Fires

Regular training in identifying and extinguishing Class B fires is critical for employees and residents. Simulation exercises and fire drills can enhance preparedness and ensure everyone knows how to respond to an emergency and use the correct fire extinguishers.

A solid emergency response plan should include clear evacuation routes, communication protocols, and designated areas for safety equipment, and use the correct fire extinguishers. This plan must be regularly updated and rehearsed.

Creating a Class B Fire Hazard Analysis and Dust Hazard Analysis

A comprehensive Fire Hazard and dust hazard analysis, (DHA), is critical for identifying and mitigating explosion risks. The dust hazard analysis process should involve the following:

- Assessment of Dust Properties: Understanding the explosiveness of the specific dust generated.

- Mapping Hazardous Areas: Identifying areas where dust is likely to accumulate and the potential ignition sources.

- Evaluating Existing Controls: Assessing current engineering and operational controls in place to prevent dust explosions.

- Recommendations for Improvement: Develop action plans to address gaps in safety measures.

The risk assessment team should include facility engineers, safety officers, and operations personnel who understand the plant’s unique processes and hazards.

Regulatory Compliance and Standards

Several safety standards and guidelines govern the handling and processing of combustible biomass dust:

- NFPA Standards: The National Fire Protection Association, (NFPA), provides detailed guidelines in NFPA 652, NFPA 654, and NFPA 664, which focus on the prevention of fires and dust explosions.

- OSHA FireFighting Guidelines: The Occupational Safety and Health Administration (OSHA) enforces standards for managing Firefighting Precautions at Facilities with Combustible Dust

Technology Advances, with the Integration of Artificial Intelligence, (AI), and Machine Learning, (ML), and Preventing Class B Fires

Recent technological advancements in Artificial Intelligence (AI), the Internet of Things (IoT), and Machine Learning (ML) are revolutionizing fire detection and prevention strategies, particularly for high-risk Class B fires involving flammable liquids and gases. AI-powered fire detection systems can now analyze vast amounts of real-time data from sensors and cameras to identify the early signs of a Class B fire, such as heat signatures, carbon dioxide, or gas leaks. These systems can automatically trigger alarms, shut down critical equipment, prevent electrical shock from circuit breakers and outlets, prevent electrical fires, or activate fire suppression systems, minimizing the risk of rapid fire spread. The IoT plays a vital role by integrating connected devices, such as gas sensors, temperature monitors, and smart extinguishers, into a unified network that continuously monitors fire-prone environments, sending immediate alerts to facility managers or emergency responders when hazardous conditions arise.

Machine Learning (ML) is enhancing predictive fire risk assessments by learning from past data to identify patterns that can lead to Class B fires. For example, ML algorithms can analyze historical incidents and identify common risk factors, such as unsafe storage of flammable materials, combustible liquids, or malfunctioning equipment. This allows industries to proactively address these risks before using fire extinguishers and an actual fire occurs. Combined with AI-driven systems, ML enables more precise and efficient fire prevention efforts, improving decision-making in high-risk industrial environments. These technologies significantly enhance safety measures in settings like oil refineries, chemical plants, and manufacturing facilities, where the threat of Class B fires is particularly high, and choosing the correct fire extinguishers.

Conclusion

Class B fires, driven by flammable liquids and gases, pose a unique and serious threat. Understanding their causes, and dangers, and proper fire extinguishers and extinguishing techniques are essential to ensuring fire safety in both industrial and residential environments.

A Class B fire involves flammable and combustible liquids like gasoline, oil-based paints, and grease, which can ignite quickly and spread rapidly. These fires require specialized fire extinguishers, often class B fire extinguishers, designed to combat such hazards effectively. However, using the wrong type of extinguisher, such as one meant for class A fires or ordinary combustibles, can exacerbate the situation. It’s crucial to understand the different fire classes to select the proper fire extinguishers. Engaging the local fire department for assistance ensures that fire safety measures and fire extinguishers are implemented safely when dealing with electrical fires, combustible liquids, flammable substances, grease, and cooking oil. The less commonly used Class F (known in the United States as Class K ) refers to fires involving cooking oil or fat. Often encountered in restaurant settings, these fires pertain to cooking oils. Class A fires and Class B fires can occur at the same time, and Class A fires are more common.

To extinguish a Class B fire, it’s essential to cut off the oxygen supply and suppress the chemical reaction that fuels it. Class B fire extinguishers typically use carbon dioxide or dry powder agents to smother the flames and prevent the fire from reigniting. For effective fire extinguisher training, it’s important to be familiar with the dangers of flammable liquids and the correct handling of portable fire extinguishers in case of fires class B. Unlike class A fires, which involve ordinary combustibles, class B fires are more hazardous due to the rapid spread of flammable and combustible liquids, requiring specialized attention. Class A fire extinguishers use water, while Class B fire extinguishers use dry chemicals (foam or powder).

In some cases, Class B fire incidents can occur near electrical equipment, leading to a mixed hazard with Class C fires. When electrical equipment is involved, using class C extinguishers is necessary to avoid electrical shock from circuit breakers and outlets. Similarly, combustible metals or class D fires also require specific extinguishing techniques to prevent accidents. Properly identifying the fire type and applying the correct extinguisher is crucial for fighting fires effectively, whether dealing with class B extinguishers for combustible liquids or class K fires related to cooking oils. Class K fires originate from cooking oils and fats like vegetable oils or grease. Taking the right fire safety precautions ensures that you handle the situation with minimal risk.

By investing in proper training, fire extinguishers, fire suppression systems, and fire safety prevention measures, individuals and organizations can significantly reduce the risk of Class B fire incidents. Stay compliant with NFPA and OSHA guidelines to prevent dangerous Class B fires, a possible chemical reaction, and explosions.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Fires and Combustible Dust, with a Podcast. Click on the latest Podcast Links: Lessons Learned from Two Sawdust Fires at a New Brunswick Lumber Mill

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.