Updated October 14, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

The Woodworking Industry and Common Sources of Wood Dust Exposure

The woodworking industry is a vibrant and essential sector that plays a significant role in the economy, producing everything from furniture and cabinetry to intricate carvings and musical instruments. However, this industry also presents unique health and safety challenges, primarily due to the generation of wood dust and cumulative exposure to wood dust, during various woodworking processes. Wood dust, a fine particulate matter released when cutting, sanding, or milling wood, is not just a nuisance, it can pose serious health risks, including allergic reactions and lung cancer, to workers if not properly managed.

Understanding the dangers of wood dust exposure, how to avoid wood dust exposure, and how to safely control wood dust is crucial for employers and employees. Prolonged or excessive exposure to dust particles, can lead to various health issues, some of which are severe and potentially life-threatening, including allergic reactions and lung cancer.

Health Risks Associated with Wood Dust Exposure

Prolonged exposure to wood dust can lead to various respiratory conditions. The most common include:

Wood dust is also a common cause of allergic reactions, and skin and eye irritation. Workers exposed to certain types of wood dust, especially hardwoods, may develop dermatitis, a condition characterized by red, itchy, and inflamed skin. Eye irritation is also prevalent, with symptoms such as redness, watering, and a gritty sensation.

- Asthma: Inhalation of wood dust can exacerbate or trigger asthma, leading to symptoms such as wheezing, shortness of breath, and coughing. Workers may develop occupational asthma, a condition directly caused by their work environment.

- Chronic Bronchitis: Long-term exposure to wood dust can inflame the bronchial tubes, leading to chronic bronchitis. Symptoms include persistent cough, mucus production, and difficulty breathing.

-

Hypersensitivity Pneumonitis: This is a rare but serious condition where the lungs become inflamed due to an allergic reaction to wood dust. Over time, exposure to wood dust can cause irreversible lung damage.

Increased Risk of Certain Cancers Associated with Wood Dust Exposure

Long-term exposure to wood dust has been linked to an increased risk of developing certain types of allergic reactions, and cancers, particularly those affecting the nasal cavity, sinuses, and lungs. The International Agency for Research on Cancer, (IARC), classifies wood dust as a Group 1 carcinogen, meaning it is known to cause cancer in humans. Hardwood dust, in particular, is strongly associated with nasal and sinus cancers. Wood dust is one of the oldest occupational exposures known to man, and it’s still very important today for people who work with cabinetry or in mills. According to a study from the Finnish Institute of Occupational Health, Helsinki, Finland, School of Health Sciences, University of Tampere, Tampere, Finland, and the Finnish Cancer Registry, Institute for Statistical and Epidemiological Cancer Research, Helsinki, Finland, Nasopharyngeal Carcinoma and Lung Cancer Wood dust is considered a group 1 carcinogen, meaning that there is much evidence showing a direct link between exposure and cancer risk.

Regulatory Standards and Guidelines for Wood Dust Exposure Limits

To mitigate the risks associated with wood dust, various regulatory bodies have established exposure limits and safety guidelines. In the United States, the Occupational Safety and Health Administration (OSHA), the National Institute for Occupational Safety and Health (NIOSH), and The American Conference of Governmental Industrial Hygienists, (ACGIH). In Great Britain, the Health and Safety Executive, (HSE), provides comprehensive guidelines on permissible exposure limits, (PELs), for wood dust:

- OSHA: Sets the PEL for wood dust at 5 mg/m³ for softwood dust and 1 mg/m³ for hardwood dust over an 8-hour workday.

- NIOSH: Recommends a more stringent limit of 1 mg/m³ for all types of wood dust to minimize health risks.

- The ACGIH has recommended a 0.5 mg/m3 Threshold Limit Value for western red cedar based on its asthma effects. Certain species of hardwood—such as oak, mahogany, beech, walnut, birch, elm, and ash— have been reported to cause nasal cancer in woodworkers. This is particularly true when exposures are high.

- HSE has established WEL limits which must not be exceeded. The exposure limits are as follows:

- Hardwood: 3mg/m3 (based on an 8-hour time-weighted average)

- Softwood: 5mg/m3 (based on an 8-hour time-weighted average)

- Mixtures of hard and softwood: 3mg/m3 (based on an 8-hour time-weighted average)

OSHA and NIOSH provide limits to worker exposures. These limits are crucial for safeguarding workers’ health. The critical metrics used are the Time-Weighted Average (TWA) and Short-Term Exposure Limit (STEL). TWA, typically measured over an 8-hour workday, reflects long-term exposure, while STEL, measured over 15 minutes, addresses the risks associated with short, intense exposure periods.

They recommend an 8-hour time-weighted average (TWA) exposure limit of 5 mg/m3 for most hard and soft wood dusts. However, there are stricter guidelines for some wood species, such as Western red cedar, which has a TWA limit of 2.5 mg/m3. The TWA is a measure that protects workers from the long-term health effects of exposure to hazardous substances by averaging exposure over an entire workday.

Specific Exposure Limits Set for Wood Dust in Different Countries

Exposure limits for wood dust vary by country, reflecting different regulatory approaches:

- European Union: Sets exposure limits through Directive 2004/37/EC on carcinogens or mutagens at work, generally aligning with NIOSH recommendations.

- Canada: Follows a similar standard to the U.S., with the Canadian Centre for Occupational Health and Safety (CCOHS) recommending limits of 1 mg/m³ for hardwood dust.

- Australia: The Australian Safety and Compensation Council sets the exposure limit at 1 mg/m³ for hardwood dust, emphasizing the importance of stringent controls.

Definition and Types of Wood Dust: Softwood vs. Hardwood

Wood dust refers to the tiny particles generated when wood is processed. These particles can vary in size, composition, and toxicity, depending on the type of wood being worked on. Generally, wood dust is classified into two categories: softwood and hardwood.

- Softwood Dust: Produced from coniferous trees such as pine, spruce, and fir, softwood dust tends to be less toxic than hardwood but can still cause respiratory and skin issues.

- Hardwood Dust: Generated from deciduous trees like oak, maple, and birch, hardwood is often more hazardous due to its finer particles and higher concentration of toxic chemicals like tannins and other natural compounds.

Properties of Wood Dust that Contribute to Health Hazards

The health risks associated with wood dust stem from several of its properties:

- Size and Shape: Fine wood dust particles are easily inhaled, reaching deep into the lungs where they can cause respiratory problems.

- Chemical Composition: Certain woods contain natural chemicals that can be irritants or allergens. Hardwood, in particular, may contain carcinogenic compounds. Pressure treated wood can also contain hazardous carcinogenic compounds. Particle board is a waste-wood product made by mixing sawdust with adhesives and resins.

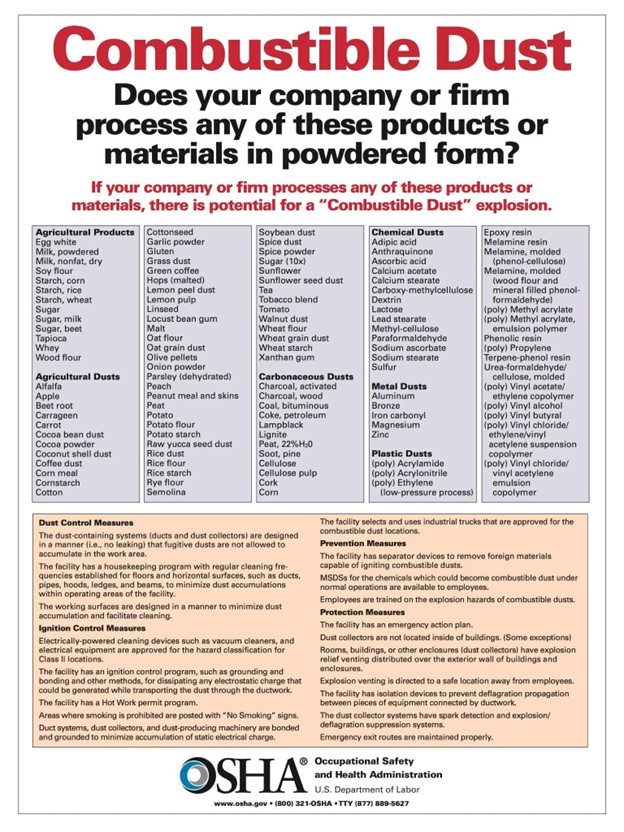

- Flammability: Wood dust is highly combustible, especially when airborne, posing a significant risk of explosions in industrial settings.

The Combustion Properties of Wood Dust in Industrial Settings

In addition to health concerns, wood dust presents a fire and explosion hazard. When suspended in the air, wood dust can form explosive clouds that, if ignited by a spark or heat source, can lead to devastating industrial accidents. The finer the dust, the more explosive it becomes, making proper dust management critical in woodworking facilities.

Wood Dust Combustion and Explosive Risks

Wood dust’s combustibility adds another layer of risk in the woodworking industry. Fine particles, such as combustible dust, can easily ignite and lead to dust explosions, which are often catastrophic. These combustible dust explosions occur when dust accumulates and becomes airborne, creating a dust cloud that can be ignited by heat sources, such as machinery, electrical sources, sparks, friction, or static electricity.

Techniques for Measuring Wood Dust Concentration and Exposure in the Air

Accurately assessing wood dust levels in the workplace is essential for maintaining a safe environment. Several techniques are employed to measure dust concentration:

- Gravimetric Sampling: Involves collecting air samples using filters and weighing the dust collected to determine concentration levels.

- Real-Time Monitoring: Uses devices such as dust monitors that provide immediate readings of dust levels in the air, allowing for quick adjustments to safety practices.

Tools and Technologies Used for Monitoring Air Quality and Wood Dust Exposure, in Real-Time

Advanced technologies have made real-time monitoring more accessible and effective. Tools like laser photometers and direct-reading instruments offer continuous monitoring of particulate levels, helping employers maintain compliance with exposure limits.

Importance of Conducting Regular Risk Assessments

Regular risk assessments are critical in identifying potential hazards and ensuring that control measures are effective. These assessments should include:

- Air Sampling: Conducted periodically to ensure that dust levels remain within safe limits.

- Equipment Checks: Regular maintenance and testing of dust collection and ventilation systems to ensure they function correctly.

- Employee Health Monitoring: Routine health check-ups for workers to detect any early signs of respiratory or skin conditions related to wood dust exposure.

Best Practices for Reducing Wood Dust Exposure

Employers can significantly reduce wood dust exposure by implementing several control measures:

- Engineering Controls: These include installing proper ventilation systems and dust collector units designed to capture dust at the source. Local exhaust ventilation (LEV) systems are particularly effective in preventing dust from becoming airborne.

- Work Practice Controls: Encourage employees to adopt practices that minimize dust generation, such as using tools with dust collection attachments. In addition, cleaning work areas regularly with ATEX and UL-rated vacuum systems for combustible dust, instead of compressed air, or shop vacs, which can disperse dust, and cause an explosion.

- Personal Protective Equipment (PPE): Providing PPE like respirators, goggles, and protective clothing is essential. PPE should be used as a last line of defense after engineering and work practice controls are in place.

Incidents Caused by Excessive Wood Dust Exposure

There have been numerous wood dust incidents, where inadequate control of wood dust has led to serious health issues and catastrophic explosions:

- The Great Boston Fire (1872): According to Wikipedia, One of the most infamous fires in American history, the Great Boston Fire of 1872 was fueled in part by a combination of combustible dust from Woodworking industries, manufactured Dry Goods, and Gunpowder. The fire started in a basement on Summer Street and quickly spread due to the abundance of wood structures and wooden mansard roofs, as they were a common architectural trend of the time. In addition, the warehouses stored Dry Goods in the eaves of the roofs, as additional sources of combustible dust.

- New England Wood Pellet (October 2011): A dust explosion occurred at the New England Wood Pellet manufacturing company. An inspection by OSHA’s Concord Area Office conducted in response to that incident identified numerous fire and explosion hazards stemming from the absence of protective devices, which were exacerbated by a buildup of sawdust on surfaces throughout the plant.

Lessons Learned from Industrial Accidents Involving Wood Dust Explosions

These incidents underscore the importance of stringent dust management practices and the need for continuous monitoring and maintenance. Key lessons include the necessity of:

- Regular Cleaning: Preventing dust accumulation is crucial in reducing explosion risks.

- Proper Ventilation: Ensuring that ventilation systems are well-designed and maintained.

- Employee Training: Workers should be educated on the dangers of wood dust and the importance of following safety protocols.

Steps for Developing an Effective Wood Dust Exposure, Management Plan

Creating a comprehensive wood dust management plan is essential for ensuring workplace safety. Key steps include:

- Risk Assessment: Identify all potential sources of wood dust and assess the associated risks, including a Dust Hazard Analysis, (DHA).

- Control Measures: Implement engineering controls, work practices, and PPE to minimize exposure.

- Monitoring and Review: Regularly monitor dust levels and review control measures to ensure they remain effective.

Integration of Artificial Intelligence (AI) and Machine Learning (ML) and Wood Dust Exposure

The integration of Artificial Intelligence (AI) and Machine Learning (ML), IoT (Internet of Things), and smart technologies is revolutionizing safety in the woodworking industry by significantly reducing wood dust exposure. AI and ML algorithms can analyze vast amounts of data from sensors and monitoring devices, identifying patterns and predicting potential hazards before they become critical.

These technologies enable the development of adaptive dust control systems that learn from real-time data, optimizing ventilation and filtration processes to maintain safe air quality levels. Furthermore, AI-powered predictive maintenance can anticipate when dust collector equipment is likely to fail, allowing for timely repairs and reducing downtime. By harnessing AI and ML, woodworking facilities can achieve more precise control over wood dust exposure, leading to enhanced worker safety, improved compliance with regulatory standards, and overall operational efficiency.

Conclusion

Wood dust exposure is a serious concern in the woodworking industry, with significantly increased risk ranging from allergic reactions, and skin irritation to respiratory problems, cancer risk, and explosive hazards. Understanding these dangers and implementing effective control measures are crucial for protecting workers and ensuring a safe work environment. Exposure to wood dust, especially in wood dust associated occupations like furniture making, can pose significant risks to worker health. Studies in occupational and environmental medicine show that high wood dust concentrations increase cancer risk, particularly for head and neck cancer and lung cancer.

The World Health Organization has identified cumulative exposure to both softwood dust and hardwood particulates as carcinogenic, especially in industries that heavily rely on woodworking equipment that generates dust. Prolonged contact with wood particles can lead to respiratory irritation, skin irritation, and more serious conditions like chronic obstructive pulmonary disease, (COPD), and developing lung cancer.

The risks of high wood dust exposure are also linked to respiratory symptoms, with common occupations linked to these conditions found in industries like furniture making, carpentry, and sawmills. These dust associated occupations may involve exposure to airborne dust and dust concentrations that vary significantly based on the type of wood being worked, whether it’s primarily softwood dust or hardwood. Dust control strategies, such as using dust collection systems and dust collectors, are essential to capture dust and remove dust from the air, thereby reducing carcinogenic risks. Proper protective measures, such as ensuring a tight seal with personal protective equipment and adhering to exposure limits, are critical to protect workers from occupational hazards and reduce the chances of developing respiratory diseases or lung-related cancers.

In Nordic countries and regions with large deciduous trees or hardwood trees, regulations often enforce stricter control measures due to the moderate evidence of lung cancer related to wood dust exposure levels. These measures aim to ensure that worker health is prioritized and occupational exposure is minimized in environments where wood particles and airborne dust are prevalent. According to the Occupational and Environmental Medicine 2015;72:889-898, a slightly reduced risk of lung cancer was noted in people in Nordic countries who were exposed to primarily softwood dust.

Employers must prioritize ongoing education, regular risk assessments, and the adoption of the latest dust control technologies to minimize exposure. By doing so, they can safeguard their employees’ health and well-being, reduce the risk of costly accidents, and ensure compliance with regulatory standards and environmental health.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional information on Wood Dust Exposure, with a Podcast. Click on the latest Podcast Links: WPAC Audit Tool for Managing Wood Dust Mitigation & Control

Resources:

Visit: Fire and Explosion Protection Equipment Providers

Visit: Risk Assessment & Dust Hazard Analysis Providers

Visit: Combustible Dust Testing Providers

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our FREE, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.