Published July 16, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

How Long Does It Take For Dust to Form?

Dust is an omnipresent substance that plays a crucial role in various environments, from households to industrial settings. Understanding how long it takes for dust to form is essential for maintaining cleanliness, ensuring safety, and preventing health hazards. In industrial environments, in particular, knowing the rate of dust formation can help in planning maintenance schedules and implementing effective dust control measures. This article will explore the factors influencing dust formation times, focusing on different types of dust such as wood dust, metal dust, and agricultural dust.

Definition of Dust and the Basics of Dust Formation

Dust consists of fine particles that originate from various sources. In industrial contexts, dust is often generated from processes such as cutting, grinding, and handling materials. Environmental dust can come from natural sources like soil erosion, pollen, and volcanic activity.

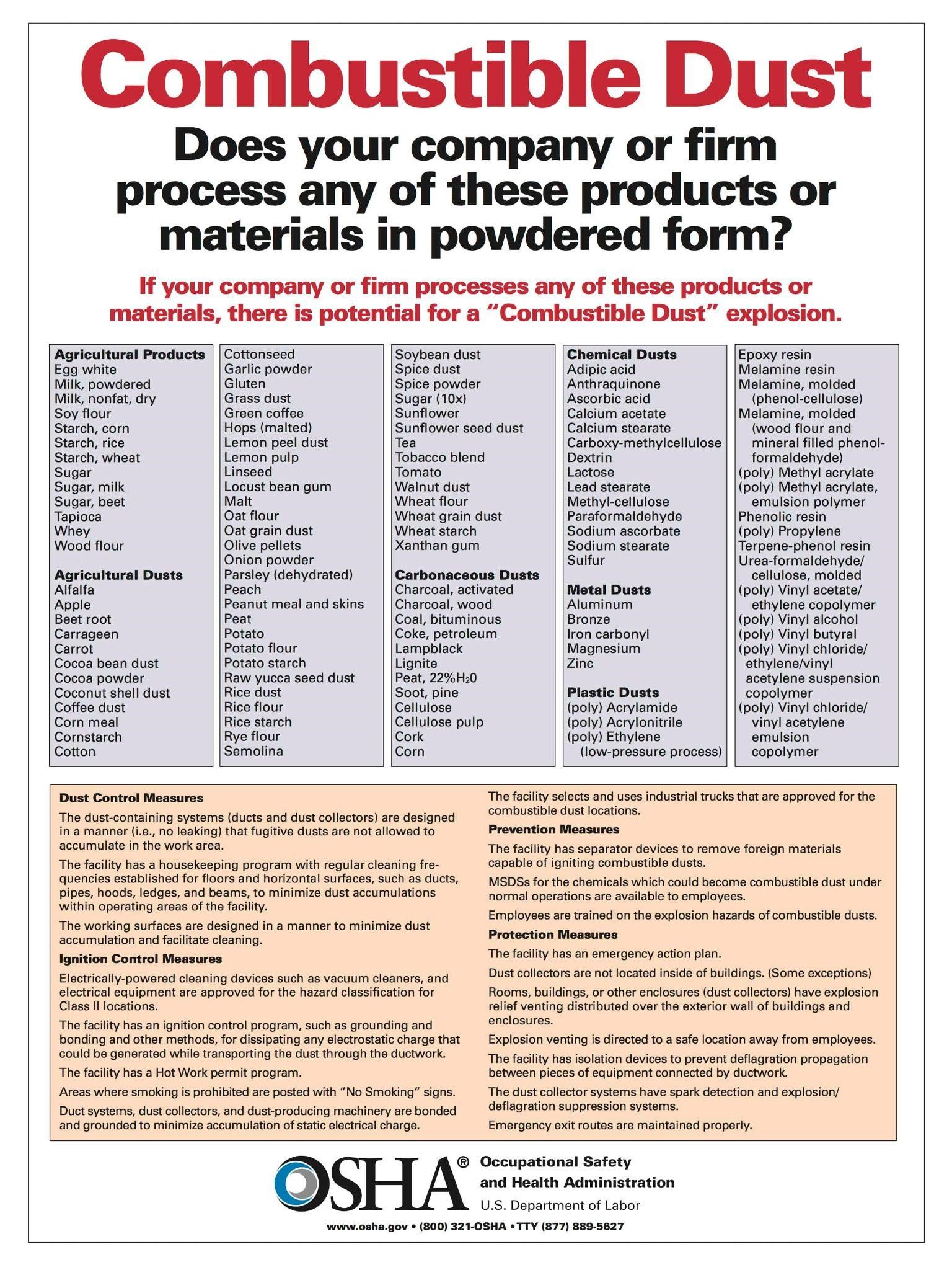

Combustible dust refers to finely divided solid particles that are prone to ignition when suspended in the air. These particles can originate from various materials and industries, including agriculture, manufacturing, and chemical processing. The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations”.

Dust qualifies as combustible when it possesses specific characteristics that make it prone to ignition and combustion when suspended in the air, and as a result, create a dust explosion. These key attributes include particle size, concentration, and chemical composition. Fine particles, often smaller than 420 microns, are more likely to ignite due to their increased surface area.

Additionally, clouds from dust must reach a certain concentration level in the atmosphere to become combustible. The chemical composition of the dust is another crucial factor, as certain materials have inherently flammable properties. Understanding these characteristics is vital for identifying and managing the risks associated with combustible dust, ensuring workplace safety and compliance from dust explosions.

Common Sources of Dust

- Manufacturing Plants: Operations involving cutting, sanding, and grinding materials like wood, metal, and plastic.

- Agricultural Operations: Activities such as plowing, harvesting, and grain handling.

- Natural Environments: Wind erosion of soil, volcanic ash, and pollen dispersion.

Physical Process of Dust Particle Separation

Dust particles are typically formed through physical processes such as abrasion, where material surfaces are worn down by friction, and fragmentation, where larger particles break into smaller ones. The process depends on the material’s properties and the forces acting upon it.

Factors Influencing Dust Formation Rate

Different materials produce dust at varying rates due to their physical properties:

- Wood: Softwoods tend to generate more dust than hardwoods due to their lower density.

- Textiles: Fabrics made from natural fibers like cotton produce more dust than synthetic fibers.

- Metals: Machining operations on softer metals like aluminum produce more dust compared to harder metals like steel.

- Organics: Agricultural products such as grains and dried plants create dust during handling and processing.

Environmental Conditions Influencing Dust Formation Rate

- Humidity: High humidity can cause dust particles to clump together, reducing airborne dust but increasing surface accumulation.

- Temperature: Higher temperatures can increase the rate of dust generation by causing materials to dry out and become more friable.

- Airflow: Increased airflow can disperse dust particles, making them more likely to become airborne.

Operational Factors Influencing Dust Formation Rate

- Machinery Operation: The type and condition of machinery can significantly influence dust production. Well-maintained equipment generates less dust.

- Production Rates: Higher production rates typically result in more dust generation due to increased material handling.

- Maintenance Routines: Regular and safe cleaning and maintenance can reduce the accumulation of dust.

Seasonal and Geographical Variations Influencing Dust Formation Rate

- Weather Changes: Dry and windy conditions can increase dust formation, while wet weather can reduce it.

- Location-Specific Factors: Areas with high industrial activity or natural dust sources like deserts experience higher dust levels.

Techniques Measuring and Predicting Dust Formation and Dust Levels

- Gravimetric Sampling: Collecting dust on filters and measuring its weight.

- Light Scattering: Using devices that measure the scattering of light by dust particles to estimate their concentration.

- Direct-Reading Instruments: Real-time monitoring devices that provide immediate dust level readings.

Predictive Models and Tools to Measure Dust Formation Rate

Predictive models use historical data and environmental conditions to estimate future dust formation rates. These models can be tailored to specific industries and environments, helping to forecast dust accumulation and plan control measures.

- Manufacturing Plants: Regular monitoring of dust levels in woodworking shops can help in scheduling cleaning and maintenance to prevent excessive buildup

- Agricultural Operations: Using predictive models to estimate dust levels during harvest seasons allows for the timely implementation of dust control strategies.

Hazards of Dust Formation and Accumulation

Dust accumulation poses several safety risks, including:

- Combustibility: Certain dust types, like wood and grain dust, are highly combustible and can cause explosions if not properly managed.

- Health Hazards: Inhalation of dust particles can lead to respiratory issues, skin irritation, and other health problems.

A Dust Hazard Analysis, (DHA), should be completed in each manufacturing facility and is a systematic review to identify and evaluate the potential fire, flash fire, or explosion hazards associated with the presence of one or more combustible particulate solids in a process or facility (NFPA 652-19).

The goal of a Dust Hazard Analysis is to identify fire, flash-fire, and explosion hazards that pose a risk to people and property.

Excessive dust formation can have significant economic impacts, including:

- Cleaning Costs: Increased frequency and intensity of cleaning efforts.

- Maintenance Expenses: Wear and tear on machinery due to dust infiltration.

- Downtime: Operational interruptions for cleaning and maintenance.

Regulatory Compliance of Dust Formation and Accumulation

Adhering to regulations, standards, and compliance, regarding permissible dust levels is crucial for workplace safety. Key standards include:

- OSHA (Occupational Safety and Health Administration): Sets limits on occupational exposure to dust.

- NFPA (National Fire Protection Association): Provides guidelines and standards, for preventing dust-related fires and explosions.

Prevention and Best Practices for Controlling Dust Formation and Accumulation

- Housekeeping: Regular safe cleaning to prevent dust buildup in confined spaces, and regular removal of dust from high surfaces to prevent dust resuspension.

- Ventilation: Ensuring adequate ventilation to disperse airborne dust.

- Enclosures: Using enclosed systems to contain dust at its source.

- Dust Collectors: Devices that capture dust at the source before it becomes airborne.

- Wet Suppression: Use water sprays to keep dust particles from becoming airborne (Disclaimer: But not for Metal Dusts and other mixing Hazards).

- Electrostatic Precipitators: Using electrical charges to remove dust particles from the air.

- Filter Replacement: Ensuring dust collection systems are functioning effectively.

Dust collector explosions are a serious hazard in many industries, including manufacturing, woodworking, food processing, and pharmaceuticals. Combustible dust in these environments creates a significant risk of explosion, which can result in severe damage, injuries, and even fatalities. To mitigate these dust collectors’ risk, it’s essential to implement comprehensive dust collection and dust explosion protection strategies. The US Chemical Safety Board, CSB, found that in all industries, dust collectors are the equipment most often involved in incidents; similarly, Zalosh et al. (2005) report that dust collectors account for more than 40 percent of all dust explosions.

Conclusion

Understanding how long it takes for dust to form and accumulate is essential for maintaining safety, efficiency, and regulatory compliance in various environments. Different materials and conditions influence dust formation rates, and measuring these rates can help in implementing effective dust control strategies. Proactive dust management not only mitigates health and safety risks but also reduces economic burdens associated with excessive dust. Continuous education and adherence to best practices are vital for ensuring a safe and clean environment.

About Dust Safety Science

Dr. Chris Cloney, of Dust Safety Science, provides additional Dust Formation and Accumulation information, with a Podcast. Click on the latest Podcast Link: Common Challenges in Combustible Dust Incident Investigation

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art fire and explosion protection.