Updated November 27, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What are Combustible Materials?

Combustible materials are substances that can easily catch fire and burn. Understanding these materials is crucial for maintaining safety in various environments, from homes to industrial settings. This article describes what constitutes combustible materials, their classifications, examples, and safety guidelines provided by reputable organizations such as OSHA, (Occupational Safety and Health Administration), and NFPA (National Fire Protection Association). Flammable and combustible materials, including combustible liquids, can be tested at an ISO/IEC 17025:2017 accredited dust & testing laboratory and can help you define whether or not you have combustible substances in your process. Noncombustible materials refer to construction materials that will not ignite, burn, or release flammable vapors. The use of noncombustible materials plays a role in the type of construction. Examples of non-combustible materials include steel, concrete, masonry, glass, and some insulating materials

Combustible Materials Scientific Composition

Combustible materials ignite and burn when exposed to an ignition source. These materials are prevalent in everyday and industrial settings, making it imperative to understand their properties and how to manage them safely. The ability of a material to combust depends on its chemical composition, physical state, and environmental conditions such as temperature and oxygen availability.

Types of Combustible Materials

Combustible materials are categorized based on their physical state: liquids, solids, gases, and dust. Each category has specific characteristics and safety considerations.

Flammable Liquids

Flammable liquids are among the most common combustible materials. Flammable liquids have a flash point, the lowest temperature at which they can vaporize to form an ignitable mixture in air, of less than 100°F (37.8°C). Examples of Flammable liquids include gasoline, acetone, and alcohol. These flammable liquids and substances can ignite and cause intense fires, making proper storage and handling crucial. The OSHA Laboratory Standard defines “Flammable liquids as: [A]ny liquid having a flash point below 100 °F. (37.8 °C.), except any mixture having components with flashpoints of 100 °F. (37.8 °C.) or higher, the total of which make up 99 percent or more of the total volume of the mixture.” Combustible Liquids as: “[A]ny liquid having a flash point at or above 100 °F. (37.8 °C.).”

Combustible Solids

Combustible solids encompass various materials, from wood and paper to plastics and textiles. These materials can catch fire when exposed to a heat source. The rate of combustion and the intensity of the fire can vary depending on the material’s properties and conditions.

Flammable Gases

Flammable gases, such as propane, methane, and hydrogen, can ignite and burn rapidly when mixed with air in certain concentrations. These gases are often used in industrial processes, heating systems, and household applications. Proper ventilation and leak detection are essential to prevent hazardous situations.

What is Combustible Dust

The NFPA, defines combustible dust as “a combustible particulate solid that presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape.”

Combustible particulates with an effective diameter of 420 μm or smaller are generally considered combustible dust. The vast majority of natural and synthetic organic materials, and some metals, can form combustible dust. The NFPA’s Industrial Fire Hazards Handbook states, “Any industrial process that reduces a combustible material and some normally non-combustible materials to a finely divided state presents a potential for a serious fire or explosion.”

Combustible dust refers to fine particles that, when suspended in the air, can ignite and cause explosions. Common examples include flour, sugar, and wood dust. Combustible dusts are often harmless in bulk form but can become hazardous when finely divided and dispersed in the air.

What Causes a Dust Explosion?

Combustible dust refers to fine particles suspended in the air, capable of igniting under certain conditions, leading to fires or dust explosions. When these particles and hazardous materials accumulate on surfaces and suspended ceilings and encounter an ignition source, the resulting dust explosion can be devastating. These airborne particles can ignite with a spark or flame, leading to combustion and potentially causing a fire or dust explosion.

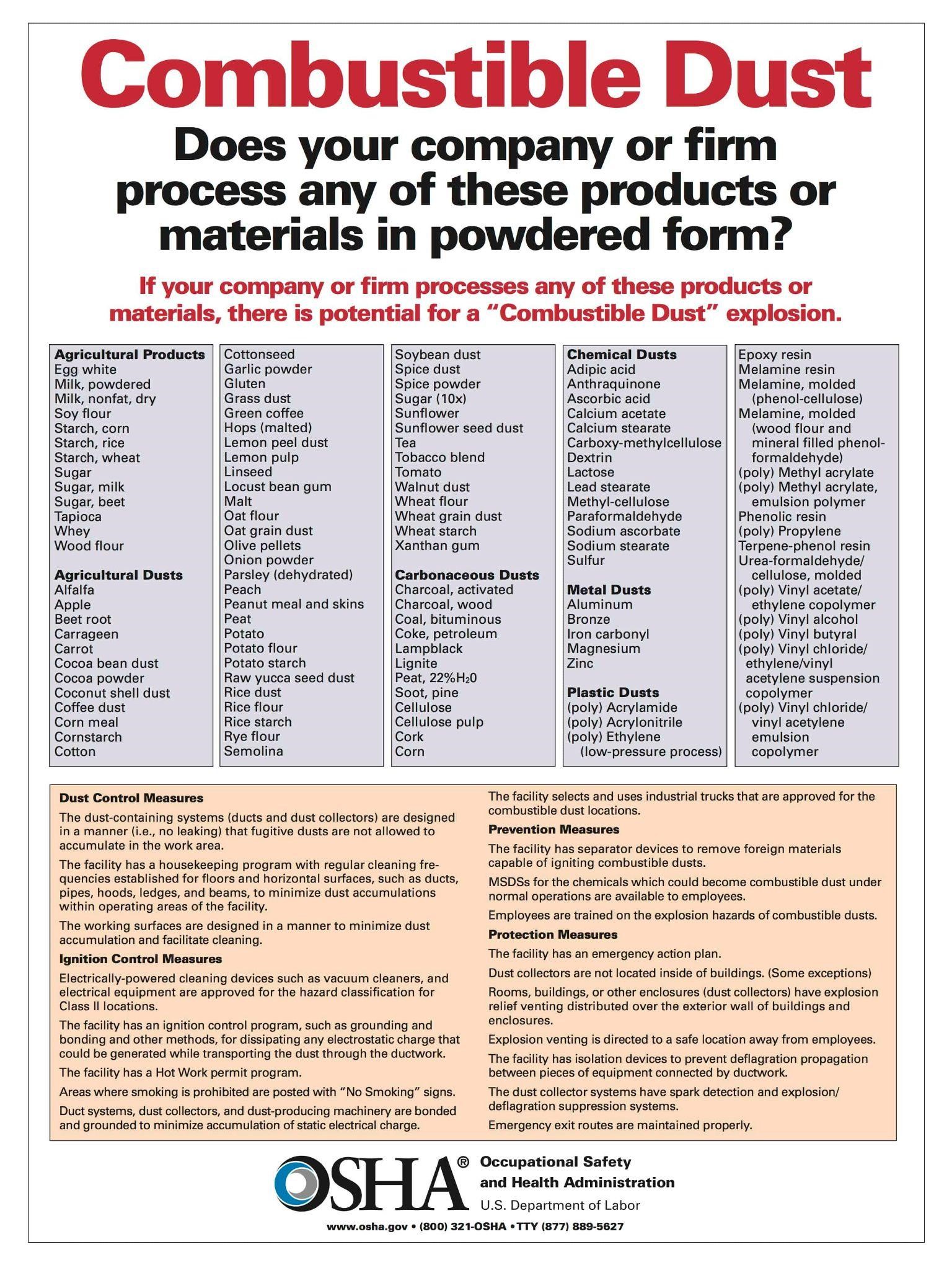

Other examples of combustible materials and products, such as grain dust, flour, paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are non combustible material in larger pieces but can be when pulverized to fine dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials. Various materials can produce combustible dust. Some common combustible materials include:

- Metals: Aluminum, magnesium, titanium

- Organic materials: Wood, grain, sugar, flour

- Chemicals: Pharmaceuticals, certain plastics, coal

Factors Influencing Combustibility

Several factors affect the combustibility of materials, including:

- Chemical Composition: The elements and compounds in a material determine its flammability.

- Surface Area: Materials with a larger surface area relative to their volume can ignite and catch fire more easily.

- Oxygen Availability: Combustion requires oxygen, and the amount available can influence the intensity and speed of a fire.

- Temperature: Higher temperatures can lower the ignition point of materials, making them more prone to combustion.

- Humidity: Moisture content can affect the combustibility of materials, with lower humidity often increasing flammability.

Safety Guidelines and Regulations

Various organizations provide guidelines and standards to manage flammable and combustible materials safely. Adhering to these regulations is crucial to prevent accidents and ensure workplace safety.

The Occupational Safety and Health Administration, OSHA, provides comprehensive guidelines for handling combustible materials in workplaces. Key regulations include:

- Hazard Communication Standard (HCS): Requires employers to inform and train workers about hazardous chemicals.

- Process Safety Management (PSM): Addresses processes involving highly hazardous chemicals to prevent accidental releases.

- Combustible Dust National Emphasis Program (NEP): Focuses on identifying and reducing combustible dust hazards.

The NFPA sets standards for fire safety and prevention, and a risk assessment, including those related to flammable and combustible materials. Important NFPA standards include:

- NFPA 30: Flammable and Combustible Liquids Code, which provides guidelines for the storage and handling of flammable liquids.

- NFPA 70: National Electrical Code, addressing electrical safety in environments with combustible materials.

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids.

Preventing Combustible Material Related Incidents

Preventing incidents involving flammable and combustible materials, and other hazardous substances and hazardous materials, requires a combination of proper storage, safe handling, transferring flammable liquids, flash point and vapor pressure awareness, and fire safety practices. Here are some key strategies for a risk assessment:

- Safety Data Sheets (SDS): Refer to the Safety Data Sheets (SDS) for each product and chemical used or stored on-site. The SDS will provide specific information about the product or chemical’s properties, health hazards, a flash point, protective measures, and safety precautions for handling, storing, and transporting the chemical.

- Segregate Flammable Materials: Store flammable materials, such as flammable liquids, solids, and gases separately to prevent cross-contamination and reduce fire risk, from flammable material.

- Use Approved Containers: Ensure that storage containers are designed for the specific type of flammable or combustible material and are properly labeled.

- Maintain Ventilation: Proper ventilation can prevent the accumulation of flammable vapors and gases.

- Training and Education: Workers should be trained on the properties of combustible materials, flammable and combustible substances, and any flammable liquid, and hazardous substances, with safe handling procedures.

- Use of Personal Protective Equipment (PPE): Appropriate PPE, such as flame-resistant clothing and gloves, should be used when handling combustible materials and a flammable liquid.

- Regular Maintenance: Equipment and storage areas should be regularly inspected and maintained to prevent leaks and other hazards, from flammable or combustible materials.

- Control Ignition Sources: Identify and control potential ignition sources, such as sparks, open flames, and hot surfaces, to prevent incidents from flammable or combustible materials.

- Implement Fire Detection Systems: Install fire alarms, smoke detectors, fire extinguishers, and sprinkler systems to quickly detect and suppress fires, from combustible and flammable materials.

Develop Emergency Plans: Establish and regularly practice emergency response plans to ensure a swift and effective reaction to fire incidents, from combustible and flammable materials.

Conclusion

Combustible materials are part of many environments, from industrial settings to everyday households and building materials. Understanding material properties, classifications, and the factors that influence their combustibility is crucial for maintaining fire safety, and the flammable materials of your building could pose a significant fire risk. By adhering to guidelines and standards set by organizations such as OSHA, and NFPA, individuals and businesses can effectively manage the risks associated with these flammable and combustible materials, and flammable and combustible liquids.

Implementing a risk assessment, with proper storage, handling, and fire prevention measures with combustible materials, and any flammable material, can significantly reduce the likelihood of combustion-related incidents, ensuring a safer environment for everyone. Stay informed, stay prepared, and prioritize safety when dealing with flammable materials and combustible materials.

Additional References:

National Fire Protection Association (NFPA): Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids

OSHA Grain Handling Safety: Combustible Materials and Combustible Dust Poster

Dust Safety Science: Examples of Combustible Dust: Where Can They Be Found?

Wikipedia: Combustion

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible Materials, visit this Podcast: Adding Combustible Dust Information to Material Safety Data Sheets

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art fire and explosion protection.