Updated December 24, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

What is the Definition of Combustible?

A combustible material is any substance that can catch fire and burn. These combustible materials can be solid, liquid, or gas. The key factor is that they require a heat source to ignite and oxygen to sustain the fire. According to Wikipedia, a combustible material is a material that can burn (i.e., sustain a flame) in the air under certain conditions. A material is flammable if it ignites easily at ambient temperatures. In other words, a combustible material ignites with some effort and a flammable material catches fire immediately on exposure to flame. According to Merriam-Webster.com, the definition of combustible is capable of combustion, highly combustible materials, and easily ignited such as paper, leaves, and sawdust. Dictionary.com, a free dictionary, states: “Combustible: capable of catching fire and burning.”

In addition, chemical manufacturing facilities also deal with combustible liquids and flammable liquids. According to Vocabulary.com, When the adjective combustible first entered the English language in the sixteenth century, it was used to describe things that burn easily. Combustible liquids, unfortunately, might be stored together with dusts, causing many hazards, and a combustible mix. A combustible substance, such as combustible liquids and dusts must be made aware to facility personnel, and the personnel must have safety training provided. A highly combustible substance can cause a catastrophic explosion.

What is Combustible Dust

The National Fire Protection Association, (NFPA), defines combustible dust as “a combustible particulate solid that presents a deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape.”

Combustible particulates with an effective diameter of 420 μm or smaller are generally considered combustible dusts. The vast majority of natural and synthetic organic materials, and some metals, can form dust. The NFPA’s Industrial Fire Hazards Handbook states, “Any industrial process that reduces a combustible material and some normally non-combustible materials to a finely divided state presents a potential for a serious explosion.” Explosive dusts are fine particles that present an explosion hazard when suspended in air under certain conditions, and set fire risks. A dust explosion can cause catastrophic loss of life, injuries, and destruction of buildings.

The Occupational Safety and Health Administration defines Combustible dust “is defined as a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations. Combustible dusts are often either organic or metal dusts that are finely ground into very small particles, fibers, fines, chips, chunks, flakes, or a small mixture of these.” Common examples include flour, sugar, and wood dust. These combustible materials are often harmless in bulk form but can become hazardous with a combustible temper, when finely divided and dispersed in the air.

In 2015, OSHA adopted the Globally Harmonized System, (GHS), of classification and labeling of chemicals. This change removed the term “combustible” from liquids, regarding OSHA standard 29 CFR 1910.106.

What Causes a Dust Explosion?

Combustible dusts refers to fine particles suspended in the air, capable of igniting under certain conditions, leading to fires or dust explosions. When these particles accumulate on surfaces and suspended ceilings and encounter an ignition source, catching fire, and the resulting dust explosion can be devastating. These airborne particles can ignite with a spark or flame, leading to combustion and potentially causing a dust explosion.

Other highly combustible materials and products, such as grain dust, flour, paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are not combustible in larger pieces but can be when pulverized to fine dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials. Various bulk materials can produce dust during handling, moving, and processing. Some common combustibility examples include:

- Metals: Aluminum, magnesium, titanium

- Organic materials: Wood, grain, sugar, flour

- Chemicals: Pharmaceuticals, certain plastics, coal

The Chimney Effect: How Fires Spread

The chimney effect, also known as the stack effect, describes how fire and smoke travel through vertical structures like chimneys, stairwells, and elevator shafts. The chimney effect plays a significant role in the propagation of dust explosions and supporting combustion. When a confined space, such as a silo or duct, experiences a dust explosion, the rapid expansion of a dust cloud or gases can create an upward draft, intensifying the fire and spreading it to other areas. This chimney effect process can lead to secondary explosions, making the initial incident even more catastrophic.

As hot air rises, it creates an upward draft, drawing more oxygen into the fire and spreading flames more quickly. Key factors of the Chimney Effect include:

- Height of the Structure: Taller structures can enhance the chimney effect, leading to more rapid fire spread.

- Temperature Difference: The greater the difference between the hot air inside and the cooler air outside, the stronger the chimney effect.

- Openings and Ventilation: Openings at different levels of the structure can facilitate the chimney effect, acting as entry and exit points for airflow.

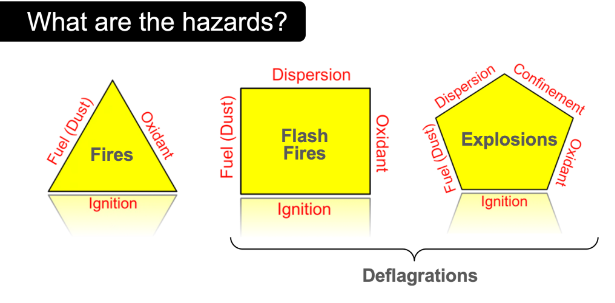

The Dust Explosion Pentagon

The Dust Explosion Pentagon illustrates the five elements necessary for a dust explosion:

- Fuel: Combustible dust particles.

- Oxygen: Present in the air.

- Heat Source: An ignition source like a spark, hot surface, or flame.

- Dispersion: Dust particles must be suspended in the air.

- Confinement: The dust and or dust cloud must be within an enclosed or semi-enclosed space.

Removing any one of these elements can prevent a dust explosion.

Combustible Dust Standards and Regulations

The Occupational Safety and Health Administration, OSHA, sets forth regulations related to grain handling facilities in the United States. These regulations, outlined in OSHA’s Grain Handling Facilities Standard (29 CFR 1910.272), cover requirements for:

- Housekeeping: Mandating regular cleaning to control dust accumulation.

- Grain Dryer Safety: Establishing guidelines for the safe operation of grain dryers.

- Preventative Maintenance: Requiring regular inspection and maintenance of equipment.

- Emergency Planning: Ensuring facilities have emergency action plans in place.

The National Fire Protection Association, NFPA, provides guidelines for the prevention of dust explosions in agricultural and industrial settings. NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities, includes recommendations for:

- Dust Control: Implementing measures to minimize dust generation and accumulation.

- Ignition Source Control: Identifying and mitigating potential ignition sources.

- Explosion Protection: Installing explosion protection systems to mitigate the impact of explosions.

Combustible Dust Explosion Prevention

Preventing dust explosions requires a multi-faceted approach:

- Housekeeping: Regular cleaning to prevent dust accumulation.

- Ventilation: Proper ventilation to avoid dust suspension.

- Dust Collection Systems: Installing dust collection systems to capture and contain dust.

- Ignition Control: Eliminating or controlling potential ignition sources.

Smoldering Fires: A Hidden Danger

Unlike open flames, smoldering fires burn slowly at the surface of combustible materials without visible flames. These fires can persist for long periods, producing smoke and potentially igniting a full-blown fire if disturbed.

Combustible Dust Examples in Industry

Different industries face varying levels of risk from dust and combustible matter. Here are some dust examples from various sectors:

In agriculture, grain dust from crops like wheat, corn, and soybeans are combustible capable and can create explosive atmospheres with a combustible temper, in silos and storage facilities. The handling and processing of these materials must be managed carefully to prevent dust accumulation.

Woodworking operations, including sawmills and furniture manufacturing, generate large amounts of wood dust. Proper dust collection systems and regular cleaning are crucial to minimize risks.

Chemical manufacturing plants often deal with powders and granules that can produce dust as a combustible substance. Ensuring proper handling and storage, along with effective dust control measures, is essential for safety. In addition, chemical manufacturing facilities also deal with combustible liquids and flammable liquids. Examples of combustible liquids include Diesel fuel, Engine oil, Fuel oil, Acetic acid, Kerosene, Linseed oil, Ethylene glycol. According to the Occupational Safety and Health Administration, OSHA, combustible liquids are “Any liquid having a flash point at or above 100 °F. (37.8 °C.).” Flammable liquids are “any liquid having a flash point below 100 °F. (37.8 °C.), except any mixture having components with flashpoints of 100 °F. (37.8 °C.) or higher, the total of which make up 99 percent or more of the total volume of the mixture.” Flammable liquids have a vapor pressure not exceeding 40 pounds per square inch (absolute) at 100 °F.” The definitions for combustible liquids and flammable liquids different under OSHA’s construction and general industry standards. The National Fire Protection Association defines the different classes of flammable and combustible liquids in its Flammable and Combustible Liquids Code, also known as NFPA 30.

Food processing facilities, processing ingredients like sugar, flour, and spices must be vigilant about dust control. Even small quantities of dust can create dangerous conditions if allowed to accumulate. In the year 2008, the Imperial Sugar Company refinery in Georgia experienced a catastrophic dust explosion. The incident resulted in 14 fatalities and 36 injuries, highlighting the severe risks associated with combustible capable dust. The dust explosion was triggered by the accumulation of sugar dust in confined spaces, which ignited and caused a chain reaction of explosions.

Metalworking processes, such as grinding and cutting, can generate fine metal dust that poses a significant explosion risk. Proper ventilation and dust collection systems are vital in these environments.

Conclusion: Staying Safe with Combustible Materials

When we think of fire hazards, we often consider open flames and obvious sources of heat. However, many combustible materials around us, including dusts, as a combustible substance, and combustible liquids are of particular concern in a work environment, and can pose significant risks under the right conditions. Combustible liquids, unfortunately, might be stored together with dusts, causing many hazards, and a combustible mix. The definition of combustible materials and combustible matter, explores concepts like the chimney effect and the dust explosion pentagon and addresses critical safety measures.

Understanding the combustible definition and the associated risks is crucial for maintaining safety in various industries. From the chimney effect and dust explosion pentagon to specific hazards like flour and magnesium fires, awareness and proactive measures can prevent disasters.

Additional References:

National Fire Protection Association (NFPA): NFPA 654

National Fire Protection Association NFPA 30 Flammable and Combustible Liquids Code, is used to classify flammable liquids and offers comprehensive requirements to help safeguard against fire and explosion hazards while storing, dispensing, handling, transferring, and using flammable and combustible liquids.

Occupational Safety and Health Administration, OSHA: Combustible Dust National Emphasis Program (NEP)

Chemical Safety Board (CSB): Imperial Sugar Company Dust Explosion

Dust Safety Science: Understanding the Dust Explosion Pentagon

NIOSH: Preventing Combustible Dust Explosions

About Dust Safety Science

For more from Dr. Chris Cloney on Gas and Dust Flames, visit this Podcast: Fundamental Differences Between Gas and Dust Flames

Resources:

Visit Latin America Dust Explosion Safety and Dust Hazard Analysis Demystified Online Training

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the-art in fire and explosion protection.