Updated November 20, 2024 Authored by Dr. Chris Cloney and Jon Barrett of Dust Safety Science

Powdered sugar, raw sugar, refined sugar, granulated table sugar, and a sugar cube are common ingredients in kitchens, in a sugar refinery, and food processing plants worldwide and can seem like a harmless sweetener. However, the sugar molecules flammability is an important aspect to consider, and requires safety measures. Like many organic substances, sugar is combustible and can catch fire under certain conditions. When sugar particles and sugar dust are dispersed in the air, they can form explosive mixtures that are highly flammable. These airborne particles can ignite if exposed to a small spark or flame, leading to a fire or explosion. Sugar and many other carbohydrates become explosive when dispersed into the air as dust. Like any organic matter, table sugar is combustible if ground down finely enough into sugar dust, increasing the surface area. Wood (made of cellulose, or lots of sugar molecules linked together), is another organic material that can cause an explosion hazard. If the concentration of airborne sugar dust is just right, and the dust is in a confined area, a simple spark could cause a large explosion, just like the Imperial Sugar refinery dust explosion.

Table sugar dust particles, and sugar molecules, when dispersed in the air in sufficient quantities, can form explosive mixtures that are highly flammable. These airborne particles and sugar molecules can ignite with a spark or flame, leading to combustion and potentially causing a fire or explosion. An electrical spark from a motor, a pump, or from ball bearings rubbing together, static electricity, or even from a light switch on a wall can set off an explosion. Other materials and products, such as paper, wood, metal, coal, plastic, cotton, and rubber that may combust in powdered form are extensive and include a wide range of materials. Some materials, such as Zinc or Potatoes are not combustible in larger pieces but can be when pulverized to fine dust. The US Occupational Safety and Health Administration (OSHA) maintains a comprehensive list of combustible materials.

The National Fire Protection Association, NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, provides guidance on dust suppression and dust control. The NFPA 654 Standard is referenced by OSHA’s Combustible Dust National Emphasis Program (NEP) to identify dust hazards and define mitigation strategies that help protect life and property. The standard provides industry-recognized safety practices for facility and systems design, process equipment protection, fugitive dust control and housekeeping, ignition source identification and control, fire protection, training and procedures, inspection, and maintenance.

The Occupational Safety and Health Administration (OSHA) in the United States defines explosive dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations.” Understanding these characteristics is vital for identifying dust hazards, managing the risks associated with dust, ensuring workplace occupational safety and compliance, and preventing a dust explosion.

Sugar is Combustible and is an Explosion Hazard

The explosive nature of sugar is primarily due to the presence of finely dispersed particles in the air. When table sugar is handled, processed, or disturbed, such as during mixing or pouring, it can release these particles into the environment. What makes sugar explode? If the concentration of sugar particles in the air reaches a critical level and encounters an ignition source, such as a spark, flame, or even static electricity, it can lead to a rapid release of energy, resulting in an explosion. A sugar refinery, may grind sugar to make confectionary powder, creating dust clouds, and cause an explosion. Grinding breaks down sugar crystals into powder, increasing the surface area of molecules. The action multiplies the surface area and presents larger surface area for combustion. A previous explosion incident at Imperial Sugar, a sugar refinery, where the processing and equipment provided an environment, that makes sugar explode. The accumulated refined sugar and powdered sugar dust, at Imperial Sugar, created a chain reaction, causing a catastrophic explosion incident. Factors like particle size, humidity levels, and the presence of other combustible materials can influence the likelihood and severity of a sugar explosion. The phenomenon of sugar dust particles exploding primarily stems from the presence of finely dispersed particles in the air. When sugar is handled, processed, or disturbed, during mixing or pouring, this process can release fine dust particles into the surrounding environment. Determining the combustibility of dust present in your facility requires professional evaluation through laboratory testing. This process involves igniting a sample of the dust in a controlled environment and analyzing key parameters to assess the potential explosion risks.

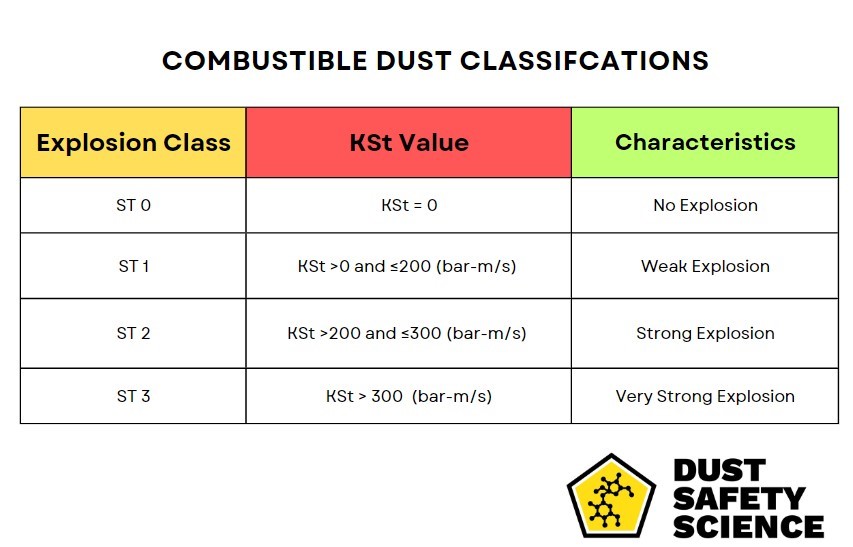

Two critical elements of this analysis are the Kst value and the Pmax value. The Kst value measures the severity of an explosion that could occur if the dust ignites, with factors such as particle size, shape, and moisture content. Meanwhile, the Pmax value indicates the maximum pressure generated by a potential explosion.

Does Sugar Explode in the Microwave?

While sugar is indeed flammable, the risk of it exploding in a microwave is relatively low compared to other cooking methods. When sugar is exposed to high temperatures in a microwave, it can heat up and potentially caramelize or burn if exposed to a spark or flame. However, the enclosed nature of the microwave and the absence of open flames or sparks typically reduce the risk of a sugar explosion. Nevertheless, caution should still be exercised when using sugar in microwave cooking.

What Other Food Dust Explodes?

Sugar is not the only food ingredient that poses a risk of explosion when dispersed as dust particles in the air. Several other food items, particularly those with high carbohydrate or sugar content, can also exhibit flammable properties under certain conditions. Flour, for example, is a well-known substance that can form explosive dust clouds when finely ground and dispersed. Other food items known to explode in dust form include powdered milk, cocoa powder, and starches such as cornstarch or potato starch. Like sugar, these substances can ignite when exposed to a spark or flame, leading to potentially dangerous explosions. Use special caution with roasting marshmallows, in camp fires as well, with the burning sugar, and ignites and burns like a torch. According to Wikipedia, Rocket candy processing includes mixing potassium nitrate and sugar, which is very explosive. In dry compression, the sugar and potassium nitrate are individually ground as finely as possible, creating an explosive environment.

Mitigating the Risks with Sugar Dust

To minimize the risks associated with sugar and other flammable food dust, various preventive measures can be implemented. In industrial settings such as food processing plants, sugar refineries such as Imperial Sugar, or other facilities handling sugar such as bakeries, proper ventilation systems should be in place to control airborne particles and reduce the likelihood of dust explosions. The explosion incident at Imperial Sugar, a sugar refinery, was a catastrophic, explosion incident to learn from. When sugar is exposed to high temperatures in a microwave, or other ignition sources, a hazardous situation can occur. Regular cleaning and maintenance of equipment can also help prevent the accumulation of dust, and a possible explosion, similar to the sugar dust at the Imperial Sugar refinery.

About Dust Safety Science

For more from Dr. Chris Cloney on Dust Suppression, visit this podcast episode: Dust Explosion And Combustion Test Methods With Dr. Ashok Dastidar.

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training, and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Complimentary, Dust Safety Science Monthly Journal

Subscribe to our Complimentary, Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on dust safety.