Updated November 5, 2024 Authored by Chris Cloney and Jon Barrett

Key Takeaways:

- Effective Combustible Dust Control: Learn how to implement robust combustible dust cleaning solutions to enhance workplace safety and prevent hazardous incidents.

- Combustible Dust Management Techniques: Explore a variety of strategies and methods for the cleaning of combustible dust, safeguarding your facility from potential ignition sources.

- Compliance and Best Practices: Stay up-to-date with industry compliance requirements and discover best practices to maintain a combustible dust-free environment, promoting a secure and efficient workspace.

Table of Contents:

- What is a Combustible Dust Explosion?

- What is Fugitive Combustible Dust Accumulation

- How to Develop a Combustible Dust Control Management Plan

- Contracting Combustible Dust Cleaning Services

- Achieving Regulatory Compliance with Combustible Dust Cleaning Services

- Different Types of Combustible Dust Cleaning Procedures

- Safe Combustible Dust Cleaning Techniques

- Explosion Proof and ATEX rated Vacuum Systems, for Combustible Dust

- Conclusion

What is a Combustible Dust Explosion?

A combustible dust explosion can be a catastrophic event, and understanding its fundamentals is paramount to workplace safety. Such explosions occur when fine particles of combustible materials, often invisible in the air, ignite in a confined space. To prevent these disasters, effective combustible dust containment, collection, and cleaning practices are essential.

Combustible dust, when suspended in the atmosphere and ignited, can lead to a rapid release of energy, resulting in devastating explosions. Our comprehensive guide will walk you through the intricacies of combustible dust explosion prevention, highlighting the importance of proactive measures in safeguarding lives and assets.

What is Fugitive Combustible Dust Accumulation

Fugitive combustible dust accumulation refers to the presence of fine particulate materials within an industrial or commercial setting that can ignite and result in hazardous explosions or fires. These dust particles, often produced during manufacturing or processing operations, can accumulate in hidden or hard-to-reach areas such as rafters, HVAC system, ventilation systems, and equipment surfaces. When left unaddressed, fugitive dust poses a significant risk to the safety of workers and the facility. A deep cleaning may be required of a combustible dust management program.

To mitigate the dangers of fugitive combustible dust, it is crucial to adopt proper housekeeping practices and establish a comprehensive combustible dust management program. This includes regular cleaning, inspection, and maintenance procedures, as well as the installation of dust collection systems, to reduce the potential for dust to become suspended in the air. Employers must also provide adequate training for their staff to recognize and handle fugitive dust hazards, as well as develop safety protocols to minimize the risk of ignition sources, such as sparks or hot surfaces, coming into contact with the accumulated dust.

In summary, fugitive combustible dust accumulation is a critical safety concern in various industries, as it can lead to catastrophic incidents if not properly managed. Effective preventive measures and stringent safety practices are essential for ensuring workplace safety and reducing the potential for dust-related accidents.

How to Develop a Combustible Dust Control Management Plan

Creating a robust combustible dust control management plan is essential for industries where fine particulate materials pose explosion and fire risks. This plan outlines proactive measures to prevent the accumulation of combustible dust and mitigate potential hazards. Key steps in developing a comprehensive dust control management plan include:

Identifying Hazards: Start by identifying the sources of combustible dust in your facility. This includes understanding the materials, processes, and equipment that generate dust.

Risk Assessment: Evaluate the severity of potential dust-related hazards, considering factors like dust concentration, ignition sources, and process conditions. This assessment informs the level of control measures needed, and to keep the work area safe, and safe work environment.

Housekeeping and Inspection: Implement regular housekeeping practices to minimize dust accumulation. Inspect areas where dust can collect, such as rafters, HVAC systems, ducts, light fixtures, window sills, ceiling fans, exhaust fans, wall hangings, wall cavities, hard to reach places, and equipment, and clean them as necessary. A deep cleaning may be required regularly, including wall cleaning, ceiling cleaning, and HVAC systems.

Dust Collection Systems: Install appropriate dust collection systems, like industrial vacuum cleaners, cyclone separators, or baghouses, to capture and contain dust at the source.

Preventive Maintenance: Establish maintenance routines to ensure the proper functioning of equipment, including dust collectors and ventilation systems, to prevent dust from escaping into the environment.

Ignition Source Control: Identify potential ignition sources, such as hot surfaces or electrical equipment, and implement safety measures to minimize the risk of sparks or flames coming into contact with combustible dust.

Training and Education: Train employees on the hazards of combustible dust and the proper use of control measures. Create a culture of safety awareness within the organization.

Emergency Response Plan: Develop a clear emergency response plan to address dust-related incidents, including procedures for evacuations, fire suppression, and medical assistance.

Documentation and Records: Maintain records of dust control activities, inspections, and training, ensuring compliance with relevant regulations.

Regulatory Compliance: Stay informed about local, state, and federal regulations related to combustible dust and ensure your plan aligns with these requirements.

Contracting Combustible Dust Cleaning Services

Selecting the right combustible dust cleaning service is crucial for maintaining safety and compliance in industrial settings. Consider the following steps to choose the most suitable professional cleaning service provider, contractor, or vendor:

- Expertise and Experience: Look for a professional cleaning service company with a proven track record and substantial experience in combustible dust cleaning. Check their credentials, certifications, and past projects to ensure they specialize in this specific field.

- Safety Protocols and Compliance: Ensure the company follows strict safety protocols and adheres to industry standards (like NFPA guidelines). Verify their compliance history and commitment to safety during cleaning processes.

- Cleaning Techniques and Equipment: Inquire about the cleaning methods and equipment used. Effective cleaning of combustible dust requires specialized tools and techniques, so ensure the company employs industry-standard tools and technologies.

- Training and Qualified Staff: Confirm that the cleaning staff are well-trained, experienced, and knowledgeable about combustible dust hazards. Ask about their training programs and certifications.

- References and Reviews: Seek references from other industrial facilities or check online reviews/testimonials to gauge the company’s reputation and reliability.

- Past Project Performance: Evaluating past performance allows you to gauge their expertise, adherence to timelines, safety protocols, equipment used for combustible dust cleaning, Personal Protection Equipment, (PPE), and overall quality of work, ensuring a reliable partnership for combustible dust cleaning projects. Scrutinize the contractor’s safety protocols and measures implemented during past projects. Focus on their strategies for mitigating combustible dust risks, utilization of safety equipment, employee training, and compliance with industry standards and regulations.

- Customized Solutions: A reliable service provider should offer customized solutions tailored to your facility’s specific needs and challenges. They should conduct a thorough assessment before proposing a cleaning plan.

- Insurance and Liability Coverage: Verify their insurance coverage and liability policies to ensure protection in case of accidents or damage during the cleaning process.

- Experience Modification Rate, (EMR), Safety Ratings: EMR is a numerical representation that indicates a company’s safety record concerning worker injuries and related compensation claims. A lower EMR signifies better safety performance, while a higher EMR may imply increased risk and potential safety concerns. Before engaging a vendor, review their safety records, including EMR ratings and past incident reports. This assessment helps gauge their commitment to safety standards and their track record in handling combustible dust cleaning tasks safely and efficiently.

- Cost and Value: While cost is a factor, prioritize the value and quality of service over price. Compare quotes from multiple contractors/vendors, and consider the overall package, including their expertise and services offered.

- Communication and Support: Opt for a company that values communication and provides ongoing support. They should be responsive to queries, offer maintenance advice, and be available for any follow-up assistance.

- Contractual Agreements and Guarantees: Review the terms of the contract thoroughly. Look for guarantees, warranties, and clarity regarding the scope of work, timelines, and responsibilities.

Achieving Regulatory Compliance with Combustible Dust Cleaning Services

Ensuring regulatory compliance is paramount when dealing with combustible dust in industrial settings. Here’s how engaging professional combustible dust cleaning services can enhance safety standards and regulatory adherence:

- Understanding Regulatory Frameworks:

Various regulatory bodies set stringent guidelines to mitigate hazards related to combustible dust. Compliance with standards like NFPA, OSHA, ATEX, and others is crucial to maintaining a safe work environment and preventing catastrophic incidents.

- Expertise in Compliance Measures:

Professional combustible dust cleaning services specialize in understanding and implementing these regulatory standards. They possess the expertise and knowledge required to ensure adherence to specific guidelines while performing cleaning tasks.

- Rigorous Cleaning Methodologies:

These combustible dust cleaning services utilize advanced cleaning methodologies that align with regulatory requirements. Their processes are designed to effectively remove combustible dust while maintaining safety standards and preventing dust re-accumulation.

- Trained and Certified Personnel:

The personnel employed by these combustible dust cleaning services undergo rigorous training and hold certifications necessary to handle combustible dust safely. Their expertise ensures compliance with safety protocols during cleaning operations.

- Enhanced Safety Measures:

Engaging professional combustible dust cleaning services not only ensures compliance but also elevates safety measures beyond minimum requirements. They go the extra mile in implementing preventive measures, risk assessments, and continual improvements to enhance workplace safety.

- Mitigating Risk of Incidents:

By aligning with expert combustible dust cleaning services that prioritize regulatory compliance, industries reduce the risk of accidents, fires, and explosions associated with combustible dust. This proactive approach safeguards both personnel and facilities.

- Continuous Improvement Culture:

Professional services often foster a culture of continuous improvement, staying updated with evolving regulations and best practices. This proactive stance ensures ongoing compliance and a commitment to elevating safety standards.

Selecting a professional combustible dust cleaning service not only ensures compliance with safety regulations but also enhances safety measures, mitigates risks, and fosters a culture of continual improvement. It’s a proactive step towards safeguarding workplaces and personnel from the hazards of combustible dust.

Different Types of Combustible Dust Cleaning Procedures

Combustible dust poses a significant safety risk in industrial settings, and adopting appropriate cleaning procedures is essential for mitigating this hazard. Different types of combustible dust cleaning procedures are designed to remove and control combustible dust accumulation, reducing the potential for explosions or fires.

Various cleaning methods and their key characteristics are given below:

Dry Cleaning: This method involves using tools like brooms, brushes, or compressed air to remove loose dust from surfaces. While cost-effective, dry cleaning can sometimes disperse dust into the air, potentially increasing the hazard if not controlled carefully. Cleaning with compressed air in particular has caused devastating explosions in the past and NFPA 652 and other standards have very stringent guidelines on when this type of cleaning is performed.

Wet/Misting/Ultra Low Volume Fogging Cleaning: Wet/Misting/Ultra Low Volume Fogging cleaning employs water or other liquid agents to suppress dust while cleaning. This method can be effective in preventing dust resuspension and is particularly useful in areas with potentially explosive dust.

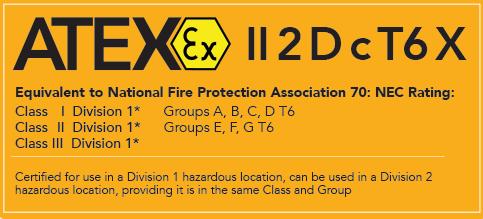

Vacuum Cleaning: Industrial vacuum cleaners designed for combustible dust removal use specialized filters and containment systems to capture dust. Vacuum cleaning is efficient, especially when equipped with HEPA filters, which can handle fine particles without releasing them back into the environment. All Vacuums must be Explosion-Proof, Anti-Static Vacuum Cleaners, Hoses and Tools, and ATEX Certified for use in National Fire Protection Association (NFPA) 70: NEC rating Class I, Division 1 (Zone 1 only), Groups A, B, C, D T6 and Class II, Division 1, Groups E, F, G T6.

Enclosure Cleaning: Enclosure cleaning systems capture dust at the source for equipment and processes that generate dust. These enclosures can be custom-designed to control dust emissions efficiently.

High-Efficiency Particulate Air (HEPA) Cleaning: HEPA filters are highly efficient at capturing fine particles, including combustible dust. When used in vacuum cleaners or air filtration systems, HEPA filters and HEPA technology significantly reduces the risk of dust accumulation and dispersal.

Dust Containment Systems: Install dust containment systems in areas where dust generation is common. These systems can isolate the dust and prevent it from spreading throughout the facility.

Regular Cleaning Schedules: Implementing a proactive and regular cleaning schedule is essential to keep dust accumulation under control. Regular cleaning reduces the risk of dust reaching hazardous levels.

Training and Safety Measures: Properly train workers in cleaning procedures and safety measures to minimize the risk of incidents during the cleaning process. Ensure that workers use appropriate personal protective equipment when dealing with combustible dust.

Safe Combustible Dust Cleaning Techniques

A Dust Hazard Analysis should be used as a first step, to safely assess whether your combustible dust exists in your manufacturing facility. Cleaning combustible dust demands meticulous methods that prioritize safety to prevent potential hazards. Here are the safest approaches, excluding compressed air and broom sweeping, commonly used in industrial settings:

Industrial Vacuums with HEPA Filtration:

Utilize industrial-grade vacuums equipped with HEPA filters specifically designed for combustible dust. These vacuums effectively capture fine particles without creating airborne dust, reducing the risk of ignition.

Wet Cleaning Techniques:

Implement wet cleaning methods using appropriate cleaning agents or dampened cloths. This technique ensures dust particles are captured and don’t disperse into the air, thereby minimizing the risk of combustion.

Localized Vacuum Systems:

Employ localized vacuum systems directly attached to machinery or workstations to capture dust at the source. This approach prevents dust from spreading and accumulating, reducing the risk of ignition in critical areas.

Scrubbers and Wet Dust Collectors:

Utilize scrubbers or wet dust collectors in areas where feasible. These systems employ water or other liquid agents to trap and remove combustible dust particles, preventing their dispersion and reducing the risk of combustion.

Non-Sparking Tools and Equipment:

When cleaning or performing maintenance in combustible dust environments, ensure the use of non-sparking tools and equipment to minimize ignition risks.

Regular Inspections and Maintenance:

Conduct routine inspections of cleaning equipment to ensure proper functioning and adherence to safety standards. Regular maintenance prevents equipment malfunction that could lead to hazardous situations.

Employee Training and Awareness:

Provide comprehensive training to employees regarding the hazards of combustible dust and the safe cleaning procedures to follow. Heightened awareness promotes a safety-conscious culture within the workplace.

Specialized Cleaning Services:

Consider engaging specialized cleaning services experienced in handling combustible dust. These professionals possess the expertise and equipment necessary to execute safe and efficient cleaning procedures.

By employing these safest cleaning practices, excluding the use of compressed air and broom sweeping, industries can significantly reduce the risk of combustible dust-related incidents. Prioritizing safety measures ensures a secure work environment while effectively managing combustible dust hazards.

Explosion Proof and ATEX rated Vacuum Systems, for Combustible Dust

In industrial settings where combustible dust poses a substantial safety hazard, specialized vacuum systems play a pivotal role in ensuring workplace safety and efficient dust control. This summary explores three critical categories of vacuum systems—anti-static, explosion-proof, and ATEX rated—and highlights their essential features.

Anti-Static Vacuum Systems:

- Purpose: Anti-static vacuum systems are designed to eliminate the risk of static electricity buildup, which can ignite combustible dust during the collection process.

- Key Features: These systems feature components and materials that dissipate static charges, preventing sparking or explosions. Conductive hoses, grounded attachments, and anti-static filters are commonly employed.

- Applications: Anti-static vacuum systems are versatile and are suitable for various industrial environments where combustible dust is a concern. They are particularly beneficial in situations where static electricity is a significant risk.

Explosion-Proof Vacuum Systems:

- Purpose: These vacuum systems are engineered to operate safely in potentially explosive atmospheres where combustible dust concentrations are prevalent.

- Key Features: Explosion-proof systems utilize non-sparking materials, sealed motors, and other safety measures to prevent ignition sources from contacting the collected dust. They are constructed to withstand the hazards of combustible dust environments.

- ATEX Certification: Many explosion-proof vacuum systems adhere to ATEX directives, ensuring compliance with European standards for equipment used in explosive.

ATEX Rated Vacuum Systems:

- Scope: ATEX-rated vacuum systems comply with ATEX regulations, which are widely adopted in Europe and other regions. These systems are certified for safe operation in areas where explosive dust is present.

- Compliance: ATEX-rated vacuum systems are designed to meet specific safety standards and categorization based on the likelihood of explosive atmospheres. Different zones are defined to classify the presence of combustible dust.

- Safety Measures: These vacuum systems incorporate features to prevent sparking and static electricity buildup, meeting the rigorous safety requirements outlined by ATEX directives.

Anti-static, explosion-proof, and ATEX rated vacuum systems are indispensable tools in industries facing the risks associated with combustible dust. Each category serves a distinct purpose, addressing static electricity concerns, potential ignition sources, and regional compliance standards. The choice of vacuum system depends on the specific needs and regulatory environment of the industrial setting.

Conclusion

This ultimate guide provides a comprehensive and up-to-date resource for understanding and managing the critical aspects of combustible dust cleaning services in various industries. The guide underscores the importance of proactive measures in preventing dust-related incidents and creating safer working environments.

Throughout this guide, we have explored the intricacies of combustible dust, including its origins, hazards, and the devastating consequences of neglecting safety. We delved into various collection and cleaning strategies, emphasizing the importance of proper housekeeping, system design, and preventive maintenance. The guide also elucidated the significance of efficient dust collection systems and their various types, as well as the benefits of using anti-static, explosion-proof, and ATEX-rated equipment in high-risk environments.

Combustible dust is a serious hazard in many industrial environments, and regular cleaning is essential for maintaining safety and compliance. Safe, high dusting and vacuum services specialize in removing dirt and debris from high surfaces like ceiling fans, light fixtures, and wall hangings, which can accumulate combustible dust. By regularly vacuum cleaning and dusting these areas, businesses can reduce fire risks and improve air quality. Using the right cleaning products and equipment, a professional cleaning company can target hard to reach places and high surfaces that may be overlooked during routine maintenance, such as ceiling beams and furniture tops.

A full cleaning approach also includes taking care of all the dust that settles on high surfaces, such as light fixtures, and lower surfaces, such as floors and walls. Many companies provide free quotes, and offer high-level dusting combined with services to wash floors, clean walls, with safe cleaning products, and vacuum dust on a ceiling fan, and around industrial facility furniture. This comprehensive cleaning routine is key to preventing dust buildup in industrial spaces, and on wall hangings, and ceiling fans. Ensuring that all high places and surfaces are kept dust-free, including a ceiling fan, reduces maintenance costs in the long term, while also creating a cleaner and safer environment for workers. For companies seeking excellent results, these services can be tailored to meet specific needs, and many providers even offer free quotes, safe cleaning products, and combustible dust rated equipment, to help determine the most effective cleaning plan.

When it comes to managing combustible dust, it is crucial to enlist experts who understand the unique needs of industrial facilities. Whether the job requires high dusting in hard to reach places, wall hangings, or a thorough cleanup of floors and equipment, hiring a specialized cleaning company ensures that the hard work is done with precision and care, and removing all the dust that accumulates. Businesses can contact these specialized cleaning services and professionals to receive customized services that address their specific dust challenges, from cleaning high level dusting areas and high surfaces on a ceiling fan, to vacuuming the floor and tackling other essential tasks. By keeping dust levels in check, companies can protect their assets and maintain a safe, efficient workspace.

In the article we discussed the array of cleaning procedures available, highlighting the importance of selecting the appropriate method based on dust characteristics and operational needs. This guide underscored that regular cleaning, maintenance, and operator training are indispensable for dust management.

About Dust Safety Science

For more from Dr. Chris Cloney on Combustible Dust Collection Systems, visit this podcast episode: Challenges With Educational Wood Shop Dust Collection Systems with Greg Slavin

Resources:

Visit Dust Safety Science (Global Incident Tracking)

Visit Dust Safety Academy (Resources, Training and Events)

Visit Dust Safety Professionals (Need Help? Get Support Today!)

Visit Dust Safety Journal for the Dust Safety Science Monthly Journal

Subscribe to our Dust Safety Science Newsletter at Dust Safety Science Newsletter

Visit the Dust Safety Science blog for written articles on combustible dust safety including the latest research, expert opinions, and state-of-the art in fire and explosion protection.